CNC Machining in Medical Device Manufacturing: An Introduction

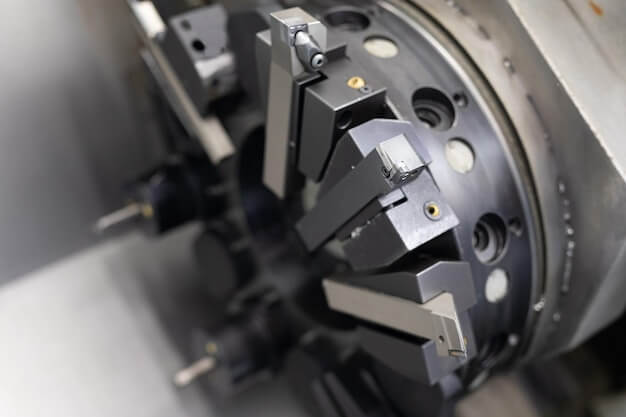

Computer Numerical Control (CNC) machining is a critical practice within the field of medical device manufacturing. This advanced technology allows for precision-engineering, ensuring anatomically correct and functional devices. CNC machining uses pre-programmed computer software to guide machinery which cuts, shapes, and forms the raw materials into final products.

The chief allure of this process lies in its precision and repeatability. It can fabricate intricate and complex medical components with high accuracy that few other methods can rival. Be it something as tiny as dental implants or larger constructs like prosthetic limbs; CNC machining can handle various scales effortlessly. Above all, the quality control is consistent throughout production, irrespective of volume.

- Titanium:Used frequently due to its durability, corrosion resistance, and compatibility with the human body. It’s favored in joint replacements, screws for fractures, bone plates, and cranial plates for neurosurgery.

- Stainless Steel:An alternative choice for surgical instruments, orthopedic devices, needles, and tubes due to its strength, corrosion resistance, and cost-effectiveness.

Overview of Materials: Titanium and Stainless Steel

Titanium, a lustrous transition metal with low density and high strength, is renowned in the medical field for its fantastic biocompatibility. This property makes it a perfect choice for orthopedic implants such as hip joints or dental implants. Furthermore, it’s resistant to corrosion and has great heat endurance.

On the other hand, stainless steel, an alloy of iron and at least 10.5% chromium content by mass, exhibits unique properties that make it essential in various industries, including medicine. Some of these key properties include resistance to both stains and rusting due to the protective oxide layer present on its surface. It also imparts excellent mechanical properties, making it a viable material for devices such as surgical instruments, cardiac stents, and bone fixation screws.

In comparing titanium and stainless steel, both offer unparalleled benefits towards specific needs within the medical sphere. While titanium outshines with great biocompatibility and less probability of rejection by the body, stainless steel proves its worth in terms of durability and cost-effectiveness. Therefore, the selection between the two depends greatly on the required application in the medical device industry.

Importance of Material Selection in Medical Devices

Choosing the right material for manufacturing medical devices is a critical decision that directly impacts the functionality and performance of these tools. The specific properties of different materials, such as tensile strength, resistance to corrosion, or biocompatibility can greatly influence how a device operates within a patient’s body.

An example of this would be hip joint replacements which are often made from either titanium or stainless steel. These two metals have distinct differences in their physical properties: Titanium, being lighter and stronger than stainless steel, provides higher durability while at the same time reducing risk of allergy and reactions as it is more bio-compatible with human tissue. On the other hand, Stainless Steel, offers high impact toughness making it resistant to cracking upon installation and use. Therefore, the choice of material utilised in the production of a particular medical device fundamentally determines its functionality and long-term success rate, painting a clear picture on why thorough understanding and careful selection of materials is vital in producing effective medical devices.

Leveraging CNC Machining for Titanium

Titanium is a highly valuable material in the field of CNC machining, especially for medical devices. Here are some key points to consider when leveraging CNC machining for titanium:

1. Properties of Titanium

- Strength-to-Weight Ratio: Titanium has an excellent strength-to-weight ratio, making it lightweight yet strong.

- Corrosion Resistance: Titanium exhibits exceptional corrosion resistance, making it suitable for medical applications.

- Temperature Resistance: Titanium can withstand high temperatures without significant deformation or loss of strength.

2. Medical Device Applications

Titanium is widely used in the manufacturing of medical devices due to its biocompatibility and strength. It is commonly used for implants, surgical instruments, and prosthetics.

3. CNC Machining Considerations

When machining titanium, several factors should be considered. Titanium has poor thermal conductivity and is challenging to machine. Specialized cutting tools and techniques are required to achieve optimal results. Additionally, proper cooling and lubrication are crucial to prevent overheating and tool wear.

4. Benefits of CNC Machining Titanium

- Precision and Accuracy: CNC machining offers high precision and accuracy, ensuring that complex titanium medical parts are manufactured to tight tolerances.

- Design Flexibility: CNC machining allows for the production of intricate and customized titanium medical components, meeting the specific requirements of medical devices.

- Efficiency and Cost-Effectiveness: CNC machining provides efficient production processes, reducing lead times and overall costs for titanium medical device manufacturing.

By leveraging CNC machining for titanium, manufacturers can harness the unique properties of this material to produce high-quality medical devices. To learn more about CNC machining services, you can explore the online CNC service provided by our trusted partner.

Leveraging CNC Machining for Stainless Steel Medical Devices

Stainless steel is often chosen as the material of choice when manufacturing medical devices using Computer Numerical Control (CNC) machining. This selection is not without justification; stainless steel has numerous advantages that are particularly suited to the stringent requirements of the medical sector. For instance, its exceptional strength and durability make it ideal for producing long-lasting surgical equipment, which can be subjected to heavy usage and high-stress environments. Additionally, one of its biggest benefits is its inherent resistance to corrosion – a critical characteristic for tools that will be in frequent contact with bodily fluids and sterilizing solutions.

- The strength of stainless steel provides long-term durability even in high-stress situations.

- Resistance to corrosion ensures safety and prolongs device lifespan.

However, like any material, there may be certain challenges posed by the adoption of stainless steel into your medical production line. Its hardness, although advantageous from an endurance standpoint, could lead to potential issues during the machining process. The toughness of the material might necessitate more powerful cutting tools or slower speeds – both factors contributing to increased manufacturing times and costs. Despite these possible challenges, with forward planning and right strategies, they can be effectively addressed and mitigated, rendering stainless steel’s pros continue to outweigh the cons in medical CNC machining applications.

- The hardness of stainless steel could increase manufacturing times and costs.

- Strategic planning can counteract these potential setbacks.

How Manufacturers Choose Between Titanium and Stainless Steel

In the field of medical device manufacturing, material selection is a crucial decision-making process. The choice often boils down to either titanium or stainless steel, largely due to their superior durability, biocompatibility, and corrosion resistance. However, manufacturers have to carefully weigh numerous factors when making this key decision.

- Firstly, they consider the intended use of the medical device. For instance, if it’s for implantation within the body or proximity to harsh biochemicals, then titanium, given its excellent biocompatibility and corrosion-resistant properties, may be the preferred option over stainless steel.

- The second factor usually taken into account involves cost-effectiveness. Although titanium offers commendable benefits, it generally commands higher costs. As such, stainless steel would be an affordable option while still retaining good levels of strength and wear-resistance.

- Finally, manufacturers inevitably factor in specifics of fabrication – machinery compatibility and ease of assembly are just as important considerations. Despite having greater strength-to-weight ratio, titanium can pose more challenges during machining compared to stainless steel due to its markedly increased hardness.

A real-world example of this deliberative process involved an orthopedic implant manufacturer. In order to ensure longevity coupled with high mechanical performance required by such implants, the company chose titanium despite the higher production cost. This decision embodies how the pivotal catalyst in choosing between these materials ultimately hinges on the functional requirements of the final product.

Conclusion

In the discussion of leveraging CNC machining for medical devices, the choice between titanium and stainless steel materials holds significant implications. We have established that both metals offer unique benefits; while stainless steel boasts cost-effectiveness and durability, titanium stands out with remarkable biocompatibility and corrosion resistance. However, shifting trends towards personalized patient care are gradually pushing manufacturers towards the use of titanium despite its costly nature.

Future challenges may include the navigation of increased costs while ensuring optimal production efficiency. As the demand for more intricate and biocompatible devices rises, manufacturers must invest in innovative machining strategies to fully exploit these materials’ potential. Thus, the success within this industry is increasingly tied to technological advancements in CNC machining processes.

Other Articles You Might Enjoy

- CNC Machining in the Watchmaking Industry: Stainless Steel vs. Titanium Cases

CNC Machining and its Role in the Watchmaking Industry In the world of horology, CNC machining has proven itself to be an invaluable tool. This modern method allows custom parts…

- Stainless Steel vs. Aluminum in CNC Machining: Pros and Cons

CNC Machining: The Role of Stainless Steel and Aluminum Computer Numerical Control (CNC) machining is a groundbreaking method in manufacturing that involves precise computer commands to manipulate and control tools…

- CNC Machining in the Watchmaking Industry: Stainless Steel vs. Titanium Cases

CNC Machining and its Role in the Watchmaking Industry In the world of horology, CNC machining has proven itself to be an invaluable tool. This modern method allows custom parts…