CNC Machining and its Role in the Watchmaking Industry

In the world of horology, CNC machining has proven itself to be an invaluable tool. This modern method allows custom parts to be generated with extraordinary precision – a key requirement in the construction of high-quality timepieces. Within this manufacturing process, materials play a crucial role in determining the quality and performance of the watch. Specifically, stainless steel and titanium are two such materials popularly used for watch cases.

- Stainless Steel: Favored for its resistance to corrosion and aesthetic appeal, stainless steel offers impressive durability that can withstand years of wear and tear. Its superior material strength also boasts remarkable scratch resistance.

- Titanium: While slightly less common than stainless steel, Titanium is renowned for being exceptionally lightweight while maintaining significant strength and resilience. It is more hypoallergenic than most other metals, making it an excellent choice for consumers with sensitive skin.

The choice between these two materials greatly influences how a final product perform and endure over time, indicating that careful consideration must be given to their selection during the design stage. CNC machining provides the capability to work seamlessly with variety of materials like these to yield exceptional watches.

Understanding CNC Machining in Watchmaking

In the watchmaking industry, CNC machining plays a crucial role in the production of high-quality watch cases. Let’s explore the importance of CNC machining in watchmaking:

1. Precision Manufacturing:

- CNC machining offers precise manufacturing capabilities, allowing watchmakers to create intricate and detailed watch cases.

- The use of advanced CNC machines ensures accuracy and consistency in the production process, resulting in high-quality watch cases.

- With CNC machining, watchmakers can achieve complex designs and precise dimensions, meeting the demanding requirements of the watchmaking industry.

2. Material Selection:

- The choice of materials for watch cases is crucial in achieving the desired aesthetics and functionality.

- Materials like stainless steel and titanium are commonly used in watchmaking due to their durability, corrosion resistance, and aesthetic appeal.

- CNC machining allows watchmakers to work with these materials, shaping them into intricate and precise watch cases.

3. Finishing Options:

- After the CNC machining process, watch cases can undergo various finishing options to enhance their appearance and functionality.

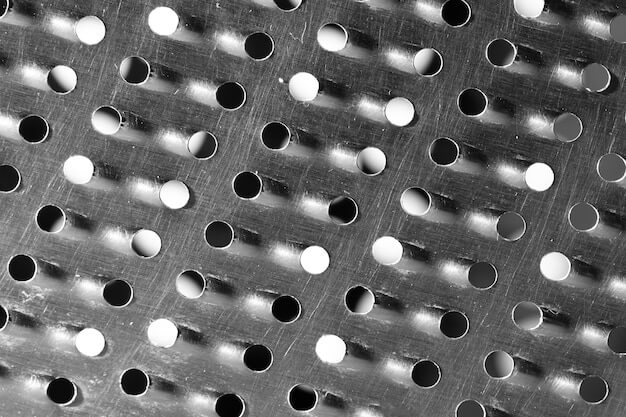

- Finishing techniques such as polishing, brushing, or sandblasting can be applied to achieve the desired surface texture and finish.

- These finishing options, combined with the precision of CNC machining, result in visually appealing and high-quality watch cases.

Understanding CNC machining in watchmaking is essential for producing exquisite timepieces. For professional CNC machining services and expert advice on watch case manufacturing, you can rely on our online CNC service.

Stainless Steel Cases: Pros and Cons

Known for its robust durability, stainless steel is a widely popular material within watchmaking industry. An alloy of iron and carbon, it embodies an optimal balance between strength and malleability, making it highly suited as a foundation for timepieces.

- Advantages: Stainless steels’ resilience to wear, tear and corrosion makes it stand apart in the field, guaranteeing long-term performance of the watches. Its ability to resist extreme environment conditions ensures the longevity of colour and shine, requiring minimal maintenance. In terms of production advantages, stainless steel’s versatility enables manufacturers to achieve intricate designs effortlessly, contributing to both aesthetic appeal and functionality of the watch cases.

- Challenges: Despite numerous advantages that stainless steel brings, there are also few drawbacks associated with its usage. One of them being its heaviness compared to alternative materials like titanium or aluminium. This might result in discomfort when worn for extended periods. Furthermore, despite its awesome resistance properties, stainless steel is not completely scratch-proof. Over time minor scratches could accumulate, thus necessitating polishing or refinishing works.

Titanium Cases: Pros and Cons

Within the watchmaking industry, titanium emerges as a viable alternative to stainless steel for CNC machined cases. Being 45% lighter than its counterpart while maintaining formidable strength, titanium proves to be more comfortable and easier on the skin due to its hypoallergenic properties.

- Merits: Titanium exhibits high corrosion resistance against acids, chlorides, and saltwater, enhancing longevity of the timepiece. It also secures higher scratch resistance than stainless steel, providing a robust exterior over time.

- Potential Complications: Despite these advantages, titanium isn’t devoid of drawbacks. Its grayish hue, compared to the brilliant sparkle of stainless steel, can limit aesthetic appeal. Furthermore, refinishing issues in case of damage pose another challenge with titanium since it requires specific techniques unlike ordinary metal-cased watches.

The choice between stainless steel or titanium is largely dependent upon a wearer’s preferences around weight, skin sensitivity, durability requirements, color, and budget constraints. Both elements present their own unique set of characteristics that contribute towards creating distinguished pieces of horology.

Stainless Steel vs. Titanium Cases: A Comparative Analysis in CNC Machining

The application of Computer Numerical Control (CNC) machining in the watchmaking industry varies greatly with the choice of materials. Particularly, Stainless steel and titanium cases have notable differences when it comes to durability, weight, comfort, and hypoallergenic properties. For example:

- Durability: While both stainless steel and titanium offer significant toughness, stainless steel typically excels in scratch resistance.

- Weight: When it comes to weight considerations in designing watches, titanium is often preferred due to its remarkable light-weight nature.

- Comfort: Here, again, titanium’s lighter weight can translate to greater comfort for wearers than its stainless-steel counterpart.

- Hypoallergenic Properties: For individuals hypersensitive to certain metals, titanium offers substantial benefits owing to its higher hypoallergenic properties compared to stainless steel.

In essence, where durable and scratch-resistant timepieces are sought-after, the use of stainless-steel cases have an edge. Conversely, titanium surpasses as a material of choice when lightweight, comfortable-to-wear, and hypoallergenic wristwatches are the main criteria.

The Impact of Material Choice on the Watchmaking Industry

Choosing between stainless steel and titanium can have a profound impact on the watchmaking industry, particularly affecting market prices, demand, and overall trends. Stainless steel is typically more affordable, which usually leads to higher demand. On the other hand, titanium watches command premium rates due to their enhanced durability and lightweight properties. For instance:

- Rolex, a prominent brand in the industry, leverages the affordability and versatility of stainless steel for majority of its models. This strategic choice contributes significantly to Rolex’s renown as a manufacturer of high-quality yet reasonably priced timepieces.

- In contrast is Tudor, who chose to be one of the pioneers in utilizing titanium cases for their Pelagos line. The use of this novel material has garnered praise from critics for their innovative approach and increased Tudor’s standing amongst luxury brands despite its relatively steeper price point.

Both examples illustrate how material choice not only influences the pricing strategy, but also shapes consumers’ perception and dictates future trends within the watchmaking industry.

Other Articles You Might Enjoy

- Leveraging CNC Machining for Medical Devices: Titanium vs. Stainless Steel Materials

CNC Machining in Medical Device Manufacturing: An Introduction Computer Numerical Control (CNC) machining is a critical practice within the field of medical device manufacturing. This advanced technology allows for precision-engineering,…

- Stainless Steel vs. Aluminum in CNC Machining: Pros and Cons

CNC Machining: The Role of Stainless Steel and Aluminum Computer Numerical Control (CNC) machining is a groundbreaking method in manufacturing that involves precise computer commands to manipulate and control tools…

- Leveraging CNC Machining for Medical Devices: Titanium vs. Stainless Steel Materials

CNC Machining in Medical Device Manufacturing: An Introduction Computer Numerical Control (CNC) machining is a critical practice within the field of medical device manufacturing. This advanced technology allows for precision-engineering,…