Machining Copper vs Aluminum: The Basics and Significance

The machining process, which centers around cutting or shaping a material using controlled removal techniques, undergoes distinctive characteristics when dealing with aluminum compared to copper. Understanding these differences is pivotal since aluminum and copper are two globally-significant metals utilized across diverse industries. Each has unique properties that impact not just the machining parameters but also influence their preferable application areas. For instance, aluminum’s lightweight yet durable nature makes it favorable in the automotive industry, while copper’s impressive conductivity results in its widespread use in electrical applications.

- Aluminum: Known for being lightweight and having high corrosion resistance. This metal’s machinability allows it to adopt complex shapes, making it ideal for creating parts in automobiles and airplanes.

- Copper: Notable for excellent electrical and thermal conductivity. However, its softness presents some challenges during the machining operation, such as sticking to cutting tools, thus asking for meticulous control over the processing parameters.

Copper and Its Properties

Copper, chemically represented as Cu, is a reddish-brown metal that ranks high in electrical conductivity. This noble metal stands out due to its unique physical properties including thermal characteristics and excellent ductility. It features an atomic number of 29 and exists naturally in a directly usable metallic form (native metals).

- Copper’s Electrical Conductivity: Copper’s role in manufacturing can be significantly attributed to its unprecedented electrical conductivity. Owing to this property, copper has become indispensable in producing electrical wires and cables.

- Thermal Characteristics: Copper also possesses great heat transfer capabilities making it a preferred choice for cookware, heat sinks, and heat exchangers.

- Ductility and Strength: In addition to being highly conductive, copper is exceptionally malleable and ductile, which allows it to be stretched into thin wire without breaking. This attribute is particularly beneficial in the construction and plumbing industries where pipes and tubes are produced extensively from copper.

Aluminum and its Properties

Aluminum, a metallic element, is third most abundant in the earth’s crust. Renowned for its lightweight characteristic, it is approximately one-third the weight of steel or copper, making it an ideal choice in manufacturing processes. In terms of physical properties, aluminum exhibits high strength versatility, exceptional thermal conductivity, natural resistance to corrosion, and durability.

- Lightweight: Aluminum weighs about 0.0975 grams per cubic centimeter, which contributes significantly to fuel efficiency in vehicles and reduces load in structures where weight plays a critical role.

- Thermal Conductivity: It carries heat well, marking its important position in cooling systems, from electronics to industrial equipment to air conditioners.

- Corrosion Resistance: Upon exposure to air, it forms an oxide layer that prevents further oxidation, providing inherent protection against corrosive environments.

- Durability: Despite being lightweight, aluminum can bear substantial loads and resist wear and tear over time, enhancing its lifespan.

The extensive use of aluminum in manufacturing covers sectors like automotive, aerospace, construction, packaging, and household items due to these unique attributes.

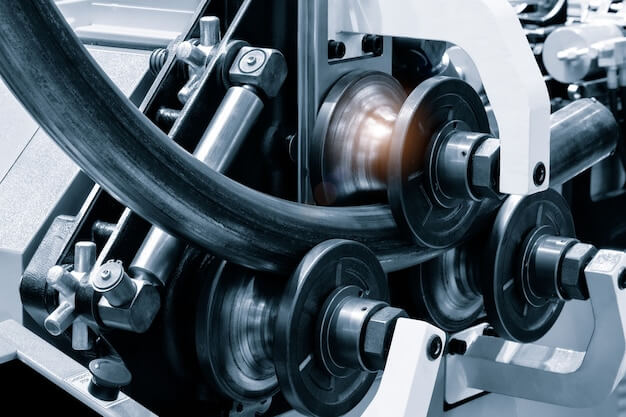

Machining Copper: Process and Challenges

Free-machining coppers are commonly used in CNC machining and rapid prototyping processes. They are suitable for electrical systems and welding torch tips. When choosing the right grade of copper for CNC machining, factors such as ductility or machinability, non-corrosive property, and general applications should be considered. The extremely high level of precision needed within the aerospace industry makes CNC machining a suitable manufacturing process for the sector. For more information on CNC machining services, you can visit the online CNC service.

Machining Aluminum: Process and Issues

The process of machining aluminum begins with the selection of the right tool. The machine operator must choose a cutting tool that is specifically designed for aluminum to ensure efficient material removal while minimizing heat generation. One of the major challenges in machining aluminum is its high thermal conductivity which can lead to rapid tool wear if not properly managed, necessitating frequent tool changes and causing delays in production runs. Further complicating the issue is the relatively soft nature of aluminum; excessive pressure during machining and improper feed rates could easily deform the workpiece. As an illustrative example, consider the plane manufacturers who require precise and intricate parts machined from aluminum. In such contexts, any aforementioned issues can result in increased production costs or even dangerous structural imperfections.

Comparison Between Machining Copper and Aluminum

The machining processes of copper and aluminum exhibit distinct differences due to the inherent characteristics of these metals. Copper, being a softer metal with a relatively high ductility, requires more care while machining as it tends to stick on cutting tools leading to smearing and elongation problems. On the other hand, Aluminum, owing to its lower strength and lesser abrasion resistance, empowers easier chip breaking making it less labor-intensive to machine.

- Differences Existence: These disparities exist primarily because of the varying physical properties like hardness, tensile strength, thermal conductivity which influence how well the metal responds in a machining environment.

- Copper Strengths & Drawbacks: Copper shines in electrical conductivity, corrosion resistance, and fantastic heat transfer attributes which make it desirable for specific applications but suffers from galling issues during machining. It also has a propensity to create long stringy chips requiring regular tool cleaning.

- Aluminum Strengths & Drawbacks: Aluminum, renowned for its lightweight nature, excellent machinability, and good corrosion resistance proves beneficial in many operations particularly where weight saving is essential. A notable drawback though is its lower resistance to wear and tear necessitating careful handling during machining.

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Online CNC Machining Quote for Precision Brass Parts

Introduction to CNC Machining and Precision Brass Parts CNC machining, or Computer Numerical Control machining, is an automated process utilized in the manufacturing industry that involves several sophisticated software-controlled machines…