Introduction to Precision CNC Machining and its Importance in High-Volume Copper Production

CNC machining refers to the process where pre-programmed computer software, known as Computer Numerical Control (CNC), dictates the movement of factory machinery and tools. This precision engineering eliminates the risk of human error, allowing a single set of manufacturing instructions to be executed with high precision. In sectors such as automotive, aerospace and electronics, CNC machining plays an instrumental role in enhancing productivity.

Effectiveness in large-scale manufacturing is best illustrated through the ability of CNC Machines to handle high-volume copper production – a critical part of many industrial processes. The use of CNC machines not only streamlines proceedings but also maintains accuracy, regardless of the quantity of copper produced. This level of precision is especially valuable in industries that require complex parts made of copper such as heat sinks for electronic devices or components for electrical systems.

Understanding Precision CNC Machining Services

Precision CNC (Computer Numerical Control) machining services play a pivotal role in high-volume copper production. These state-of-the-art technological procedures offer unparalleled accuracy, consistency and versatility in manufacturing numerous parts with complex geometries.

- The core principle of precision CNC machining revolves around computer-controlled systems that perform intricate operations, actually eliminating the possibility of human errors.

- What makes this service unique is its ability to replicate exact copies of a digital CAD model while maintaining precise measurements throughout mass production runs.

- Another notable aspect of precision CNC machinery is their automated nature – they operate round-the-clock requiring minimum intervention.

- This not only increases efficiency but also reduces production costs due to less labor involvement and reduced waste.

In summary, Understanding Precision CNC Machining Services provide significant benefits for bulk copper production; from flawless replication of intricate designs to consistent quality output and operational efficiencies.

Key elements involved in precision CNC machining service for high-volume copper production:

- Material Selection: Choosing the right grade of copper for CNC machining involves considering factors such as ductility, machinability, non-corrosive properties, and general applications.

- Production Volume: Large orders can significantly affect the cost of CNC milling services, as economies of scale reduce the cost per milled item, making it more cost-effective for high-volume copper production.

- Quality Assurance: Precision CNC machining services should prioritize quality assurance to ensure that high-volume copper production meets industry standards and requirements.

Precision CNC Machining: An Indispensable Element in High-Volume Copper Production

In the landscape of high-volume copper production, precision CNC machining holds substantial relevance. This is primarily due to its capability to deliver consistent quality and uniformity at a scale that fits large output requirements. The inherent characteristic of precise computer-guided toolpaths enables it to reproduce parts with incredible accuracy, reducing instances of wastage and reworks caused by inaccurate cuts or misalignments.

- The first advantage is operational efficiency. By utilizing computer numerical control (CNC), manufacturers can automate much of the copper manufacturing process increasing throughput rates while minimizing errors.

- Secondly, Precision CNC machining’s exceptional repeatability ensures every copper component produced matches exact specifications, crucial for massive production runs where consistency is vital.

- Lastly, investment in this technology results in significant cost savings over time through reduced labor costs, minimized material waste, and faster production cycles.

Given these benefits, the place of precision CNC machining in high-volume copper production is not only justified but also indispensable.

Key Elements Involved in Precision CNC Machining Service

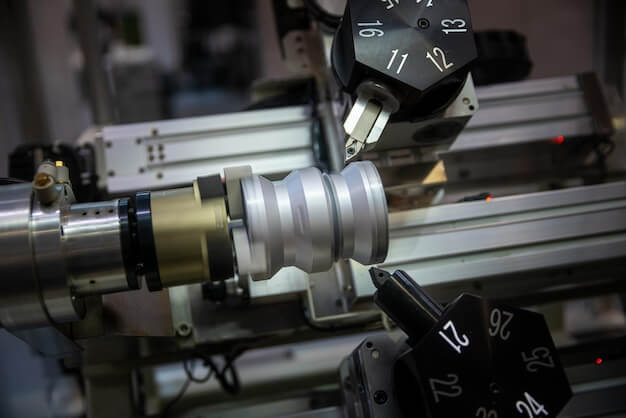

Precision CNC machining services involve several key elements crucial for high-volume copper production. Firstly, the Computer Numerical Control (CNC) system is vital to automating precise machine movements with software commands. This eliminates human errors while improving efficiency and speed. Secondly, cutting tools such as lathes, mills or drills are used under computerized control that cuts into the copper components resulting in intricately designed products.

- The choice of materials also plays a significant role; High-strength copper alloys utilized ensure durability and resilience against wear-and-tear during production processes.

- Software platforms and simulation algorithms ensure precision by mapping out complex pathways and providing real-time feedback on possible collision points, torque constraints, and optimization routes prior to actual operations.

- Maintenance practices assure sustained operation & longer service life of the machines. Regular inspection helps detect any challenges early enabling proactive problem-solving without disruptive effect on output quality or volume.

In conclusion, these elements seamlessly work together in precision CNC machining to drive efficient and high-quality copper production liberating industries from labor-intensive traditional methods thus, enhancing productivity.

Understanding CAD and CAM in CNC Machining

In Precision CNC machining, Computer-Aided Design (CAD) plays a pivotal role. The designing process begins with CAD where engineers create a 3D model of the part to be manufactured. This digital model serves as a virtual blueprint and accompanies every step of the manufacturing journey. By using CAD software, intricate details can be added onto the design enhancing its precision. Furthermore, due to its digital nature, design modifications can be made effortlessly whenever required.

- The CAD process starts with drafting a basic geometric shape of the component part.

- Gradually, more specific details like dimensions, surface textures are added onto the design.

- Digital simulation tools allow visualization of how the part will function which helps in prediction and elimination of any possible errors upfront.

Following the completion of the design process via CAD, the production is handled by Computer-Aided Manufacturing (CAM). The 3D models created through CAD are fed into the CAM system, and their input initiates the actual machine movements during production. It translates the digital model into G-code – a specialized language that instructs the CNC machines about tool paths, cutting speeds etc. Hence, ensuring an efficient and error-free manufacturing process.

- CAM analyses the most efficient sequence and method for machine operations

- G-Codes generated by CAM directs machinery on what cuts to make and where to position – guaranteeing precision

- It also assist in managing resources and controlling quality checks throughout the process

Pros and Cons of Using Precision CNC Machines for Copper Production

The use of precision CNC machines in copper production offers several advantages. Primarily, they offer high-volume production due to mechanized operations that result in minimal human intervention and subsequently fewer errors. High-level accuracy and consistency are other notable benefits brought about by these advanced pieces of machinery. An ideal scenario demonstrating this is the manufacture of precision parts required in aerospace equipment; even small deviations from specified parameters can lead to catastrophic failures but with precision CNC machines ensuring consistent output, such risks are significantly mitigated.

- Benefits:

- High volume production due to mechanized operations

- Consistency and accuracy in production

However, there are potential challenges linked to relying on precision CNC machining services for copper production. The initial cost investment in these sophisticated machines can be hefty, which may not be feasible or practical for all businesses. Additionally, skilled operators are needed to manage these complex systems properly, leading to increased overhead costs. Lastly, while their automation reduces labor intensity, it also presents a dependency issue whereby if the machine breaks down, production is halted.

- Drawbacks:

- High initial investment cost

- Crucial requirement for skilled operators

- Potential stoppage of production during machine breakdowns

Efficiency Factors: Enhancing High Volume Production Via Precision CNC Machining Services

The efficiency of high-volume copper production can be significantly enhanced through the use of Precision CNC machining services. These technologically advanced machines streamline processes and improve productivity by carrying out complex tasks in a shorter time span compared to traditional manufacturing methods. The precision inherent in CNC machining minimizes errors, ultimately resulting in less waste – an important factor when dealing with volumes of costly raw materials such as copper.

- CNC machines automates tasks which reduces operator intervention, thereby decreasing chances of human error and increasing speed of production.

- Precision CNC machining follows exact instructions from digitized plans, meaning every cut or move is accurate and consistent down to the minutest detail. This not only leads to consistency across high-volumes but also eradicates wastage that may occur due to inaccuracies or irregularities.

In essence, the unrivaled accuracy, speed and automation offered by Precision CNC machining service providers equate to efficient high volume copper production with almost zero margin for error. For instance, a fabrication company producing thousands of identical copper components was able to double their output while reducing material costs by opting for Precision CNC machining over conventional alternatives. Hence, it’s evident that investing in these services are detrimental for businesses aiming at optimizing their production line and maximizing profit.

Cost Implications: An Analysis of Affordability

In the initial phase, the expenses associated with the installation, maintenance, and training for Precision CNC Machining Services might appear steep in contrast to manual labour costs. However, a detailed cost comparison highlights how this upfront investment can offer significant financial benefits in the long run.

- Affordability: When compared to manual labour, the costs of running CNC machinery may be equivalent or slightly higher due to electricity consumption and machine maintenance. Yet, the real value emerges over time as these machines are capable of operating around the clock with minimal downtime, unlike human labour constrained by working hours and breaks, leading to increased productivity.

- Long-term Financial Benefits: Precision CNC machining offers clear advantages for high-volume copper production. It reduces waste and material costs through precise, repeatable cuts which minimises errors, rework and scrap that would otherwise be common with manual intervention. In addition, it lowers labour costs because fewer workers are needed to operate the systems. Over time, these savings contribute significantly to bottom-line profitability.

Hence, companies must take into account these vital considerations when assessing the cost-effectiveness and affordability of adopting precision CNC machining services versus relying on manual labour.

Final Outlook on Precision CNC Machining Services for High Volume Copper Production

The paramount importance and significant benefits of employing precision CNC machining services in high volume copper production cannot be understated. This advanced technology ensures efficient, accurate, and quick manufacturing processes that guarantee excellent quality products which meet the stringent standards expected in various industries. The introduction of precision CNC machining has revolutionized copper production by providing supreme accuracy, consistency, and repeatability- attributes critical for meeting bulk orders without compromising on product quality.

- Efficiency: Integrating these services into your manufacturing process can significantly enhance productivity by reducing manual labor and downtime, thereby saving costs.

- Accuracy: These machines perform tasks with incredible precision, leading to a reduction in errors and waste materials. This boosts overall profitability while maintaining top-tier quality.

- Consistency: When dealing with large-scale productions, achieving consistency can often pose challenges. However, precision CNC machining guarantees uniformity regardless of the volume, enhancing customer satisfaction and brand reputation.

In tandem with the rapid evolution of technological advancements, it is highly encouraged for stakeholders within the manufacturing industry to embrace and seamlessly integrate precision CNC machining services within their operations. Harnessing this innovative advancement not only aids in bolstering efficiency within the workspace but also sets forth market competitiveness and future business growth.

Other Articles You Might Enjoy

- Unlocking New Possibilities in CNC Machined Titanium Medical Devices

Introduction to CNC Machined Titanium Medical Devices The prevalence of CNC machined titanium medical devices in the healthcare sector demonstrates their immense significance and usefulness. This technology furnishes an essential…

- CNC Aluminum Machining Services: Advanced Techniques for Perfect Parts

CNC Aluminum Machining Services In the current manufacturing landscape, CNC aluminum machining services play a pivotal role. CNC which simply translates to 'Computer Numerical Control', is an advanced technique used…

- Hastelloy vs. Stainless Steel in Chemical Processing Equipment: CNC Machining Perspectives?

Hastelloy vs. Stainless Steel in Chemical Processing Equipment: An Introduction In the realm of chemical processing equipment, two commonly used materials include Hastelloy and stainless steel. Hastelloy, a reputed superalloy…