Introduction:

As an engineer who’s spent years designing thermal solutions for data centers and renewable energy systems, I’ve seen firsthand how a large heat sink can make or break a project. From stabilizing CPUs in high-performance servers to ensuring IGBTs in solar inverters don’t overheat under scorching desert conditions, a large heat sink is the unsung hero of modern electronics. In this guide, I’ll share my insights, blending technical analysis with practical experiences, to help you master the art of thermal management using large heat sinks. We’ll explore thermodynamics, material science, advanced manufacturing like CNC machining, and system design, all grounded in lessons I’ve learned in the field.

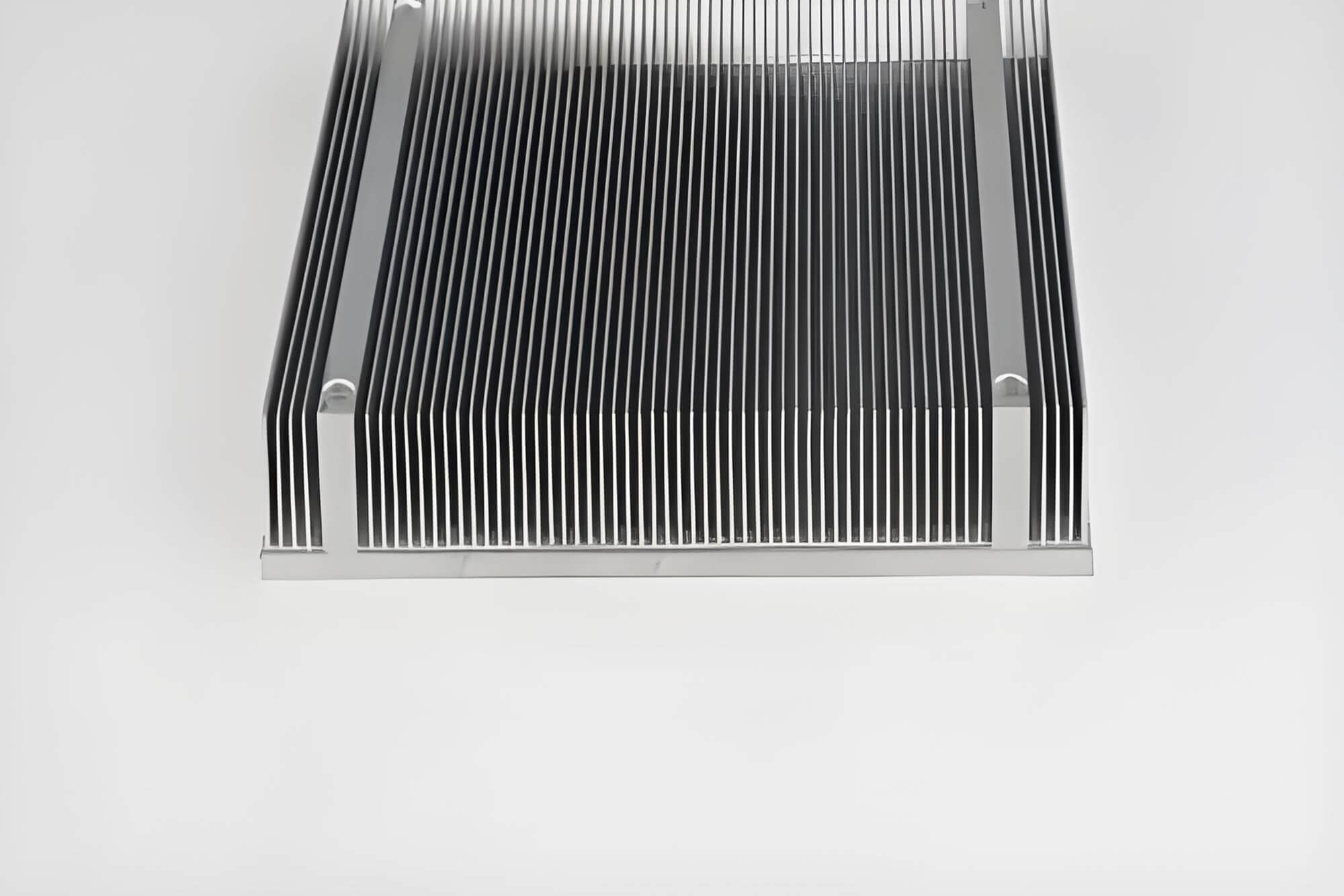

The Foundational Role of Large Heat Sinks in Thermal Management

I’ve always viewed a large heat sink as more than just a chunk of metal—it’s a meticulously engineered system that absorbs and dissipates massive amounts of waste heat to keep critical components at safe temperatures. Whether it’s cooling telecommunications equipment or high-performance computing clusters, a large heat sink is my go-to solution for preventing performance throttling or catastrophic failure. Early in my career, I underestimated their importance, but after a server rack overheated during a critical test, I learned that a well-designed large heat sink is non-negotiable for reliability.

Defining Large: Thermal Capacity Over Physical Size

From a thermodynamic perspective, a large heat sink acts like a heat reservoir, soaking up significant heat with minimal temperature rise. In my work on electric vehicle (EV) charging stations, I’ve designed large heat sinks—often shaped with CNC machining for precision—to handle the intense thermal loads of power modules. For instance, in a 150 kW charger, a large heat sink with ample surface area ensured MOSFETs stayed below 85°C, even in 40°C ambient conditions. This experience taught me that size isn’t just about dimensions; it’s about thermal capacity tailored to the application.

The Core Laws of Heat Transfer: Conduction, Convection, and Radiation

The performance of a large heat sink hinges on three heat transfer mechanisms, which I’ve wrestled with in countless designs:

- Conduction: Heat flows from the component through the large heat sink base. I once overlooked the importance of a high-quality thermal interface material (TIM), resulting in a 15°C temperature spike due to poor contact. Lesson learned: never skimp on TIM quality.

- Convection: This is where a large heat sink shines, transferring heat to air via natural or forced airflow. In a data center project, switching to forced convection with fans slashed the R_th of a large heat sink by nearly 70%, saving the design.

- Radiation: In passive large heat sinks, radiation can be a game-changer. I recall a telecom project where black anodizing, applied during CNC machining, boosted radiative heat loss by 25%, allowing a passive large heat sink to handle a 100W load without fans.

The Critical Metric: Calculating Thermal Resistance (R_th) for Large Heat Sinks

Thermal resistance (R_th, in °C/W) is the North Star for evaluating a large heat sink. It measures how much the temperature rises per watt of heat dissipated—lower is better. The total thermal resistance (θ_JA) includes:

- θ_JC (junction to case)

- θ_CS (case to large heat sink, via TIM)

- θ_SA (large heat sink to ambient)

To calculate the required R_th for a large heat sink, I use:

Rth=(Tcasemax−Tambientmax)/Pdissipated

For example, in a 5G base station project, I needed a large heat sink to manage a 120W IGBT with a max case temperature of 90°C in a 45°C environment. The math pointed to an R_th of 0.375°C/W, which guided my selection of a CNC-machined large heat sink with optimized fins. My advice? Always check manufacturer R_th curves against your system’s airflow—ignoring this once cost me a redesign when a large heat sink underperformed at low airflow.

Material Selection: The Backbone of Large Heat Sink Performance

Choosing the right material for a large heat sink is a balancing act I’ve navigated many times, weighing thermal conductivity, weight, cost, and manufacturability. CNC machining has been a lifesaver for creating tailored designs that maximize performance.

Aluminum vs. Copper: Lessons from the Field

- Aluminum: My default for most large heat sinks due to its lightweight nature, solid conductivity (~201 W/mK for alloy 6063), and affordability. In a wind turbine controller, I used an aluminum large heat sink machined via CNC machining to save weight without sacrificing cooling.

- Copper: Its superior conductivity (~400 W/mK) makes it ideal for compact large heat sinks in high-heat-flux scenarios, like GPU cooling. But copper’s weight and cost can be brutal—I once swapped a copper large heat sink for aluminum to cut costs by 40% without performance loss.

Aluminum Alloys for Large Heat Sinks

- 6063/6060: My go-to for extruded or CNC-machined large heat sinks due to their balance of conductivity and formability.

- 6061: Stronger and corrosion-resistant, perfect for large heat sinks in harsh environments like marine inverters.

- 1050A/1100: High-conductivity alloys for large heat sink spreaders, often shaped via CNC machining for precision.

Here’s a table I often reference when selecting materials:

| Property | Aluminum (Alloy 6063-T5) | Copper (CDA 110) | Key Considerations |

| Thermal Conductivity (W/mK) | ~201 | ~400 | Copper excels in heat spreading but is costlier. |

| Density (g/cm³) | ~2.7 | ~8.9 | Aluminum is ideal for weight-sensitive designs. |

| Relative Cost (Raw Material) | 1.0x (Baseline) | ~3.0x+ | Aluminum suits large-scale production. |

| Specific Heat Capacity (J/kg⋅K) | ~900 | ~385 | Aluminum absorbs more heat, great for transient loads. |

| Manufacturing | Excellent for extrusion and CNC machining | Difficult to machine; no extrusion | Aluminum enables complex, cost-effective designs. |

Manufacturing Processes: Crafting Large Heat Sinks with Precision

The way a large heat sink is made defines its performance and cost. I’ve worked with various methods, each with trade-offs:

- Extrusion: My first choice for cost-effective aluminum large heat sinks in high-volume projects like consumer electronics. But its fin geometry limits pushed me to explore alternatives for high-power applications.

- Skiving: Creates high-density fins for compact large heat sinks, perfect for server GPUs where space is tight.

- Bonded-Fin: I’ve used this for hybrid large heat sinks in telecom systems, combining copper bases with aluminum fins for optimal heat spreading and dissipation.

- CNC Machining: My go-to for prototypes or mission-critical large heat sinks. In an aerospace project, CNC machining allowed me to integrate cooling channels into a large heat sink, boosting performance by 20%.

Here’s a table I use to guide manufacturing decisions:

| Manufacturing Method | Thermal Performance | Fin Density / Aspect Ratio | Design Flexibility | Relative Unit Cost (at scale) | Ideal Applications |

| Extrusion | Low to High | Limited | Moderate | Low | General-purpose, consumer electronics, industrial power supplies |

| Skiving | High to Very High | High | Moderate | Medium | High-power density servers, GPUs, compact electronics |

| Bonded-Fin | High to Very High | Very High | High | High | Very large power modules, telecom, renewable energy systems |

| CNC Machining | Very High | Very High | Very High | Very High | Prototypes, aerospace, highly complex or integrated designs |

System-Level Cooling Architecture: Passive, Active, and Liquid Solutions

Passive Cooling with Large Heat Sinks

I’ve always appreciated the simplicity of passive large heat sinks—no moving parts, no noise, just pure reliability. In a rural telecom enclosure, a CNC-machined large heat sink used natural convection and radiation to cool a 75W module silently, a lifesaver in a dust-prone environment. But their large volume makes them impractical for high-density systems.

Active Air Cooling for Large Heat Sinks

Adding fans to a large heat sink is like turbocharging your cooling. In a data center retrofit, I paired a large heat sink with 400 LFM fans, cutting R_th by 60% and saving a rack from overheating. The trade-off? Fan noise and maintenance, which I’ve learned to plan for.

Liquid Cooling with Large Heat Sink Radiators

For extreme cases, like a supercomputing cluster, liquid cooling with a large heat sink radiator is unmatched. I once designed a CNC-machined large heat sink for a liquid-cooled system handling 600W, keeping junction temperatures below 70°C. The complexity is daunting, but the results are worth it.

Hybrid Cooling Systems

My favorite approach is hybrid cooling, blending passive and active modes. In an automotive radar project, I used a large heat sink for passive cooling during standby, with fans kicking in during peak loads. This balance saved power and kept noise low, a win for both performance and user experience.

Advanced Design and Optimization for Large Heat Sink Performance

Optimizing Fin Geometry in Large Heat Sinks

Fin design is where I spend hours tweaking:

- Shape: Straight fins for forced convection, pin fins for passive large heat sinks. I learned this the hard way when a pin-fin large heat sink outperformed straight fins in a low-airflow test.

- Spacing: Too tight, and airflow chokes; too wide, and you lose surface area. I aim for 2–6 mm spacing in forced convection designs.

- Height/Length: Longer fins add area but hit diminishing returns. CNC machining lets me sculpt precise fin profiles to sidestep thermal boundary layer issues.

Simulation Tools: I rely on CFD software like ANSYS Fluent to simulate airflow and heat transfer, saving me from costly prototyping errors when designing large heat sinks.

The Role of Thermal Interface Materials (TIMs)

Early in my career, I underestimated TIMs, thinking any thermal paste would do. A 10°C temperature spike in a GPU test taught me otherwise. Now, I insist on high-quality TIMs, like graphene-enhanced pastes, to minimize θ_CS between the component and the large heat sink.

A Practical Framework for Selecting Your Large Heat Sink

Here’s the process I’ve honed over years:

- Define Thermal Requirements: Calculate R_th for the large heat sink using the equation above, factoring in worst-case conditions.

- Assess Constraints: Evaluate space, weight, airflow, and noise limits. I once scrapped a design because a large heat sink was too heavy for a portable device.

- Evaluate Trade-Offs: Choose materials and methods like CNC machining for precision or extrusion for cost, based on project goals.

- Specify and Source: Work closely with suppliers, demanding R_th curves and material certifications to ensure the large heat sink performs as expected.

My Tip: Collaborate with manufacturers early. In a recent project, co-designing a CNC-machined large heat sink with a supplier shaved 15% off production costs while meeting thermal targets.

Conclusion:

Designing large heat sinks has taught me to respect the interplay of science, engineering, and practical constraints. Whether it’s a CNC-machined large heat sink for a prototype or an extruded one for mass production, the right choice can transform a system’s performance. I hope my experiences and this guide empower you to build robust, reliable thermal solutions for your next project.

FAQ:

1. What is a large heat sink, and why is it critical for high-power electronics?

A large heat sink is a thermal management component designed to absorb and dissipate significant waste heat from high-power devices like CPUs, IGBTs, or LEDs. In my experience designing data center cooling systems, a large heat sink prevents overheating, ensuring performance and longevity. Its large surface area and mass, often shaped via CNC machining, make it ideal for applications like renewable energy inverters or 5G base stations, where thermal stability is non-negotiable.

2.What materials are best for large heat sinks, and when should I choose aluminum over copper?

Aluminum and copper are the primary materials for large heat sinks. Aluminum (e.g., alloy 6063) is lightweight, cost-effective, and great for extrusion or CNC machining, making it my default for applications like EV chargers. Copper, with ~400 W/mK conductivity, suits compact large heat sinks in high-heat-flux scenarios, but its weight and cost are drawbacks. In a GPU cooling project, I switched from copper to aluminum to save 30% on costs without compromising performance.

3. What manufacturing methods are used for large heat sinks, and how do they impact performance?

Common methods include extrusion, skiving, bonded-fin, and CNC machining. Extrusion is cost-effective for aluminum large heat sinks in mass production, but limited in fin density. Skiving creates high-density fins for compact designs, while bonded-fin allows hybrid large heat sinks for high-power telecom systems. CNC machining, my go-to for prototypes, offers precision for complex large heat sinks, like those in aerospace with integrated cooling channels.

4. When should I use passive cooling versus active cooling with a large heat sink?

Passive cooling, relying on natural convection and radiation, is silent and reliable but requires a bulky large heat sink. I used a CNC-machined large heat sink for a rural telecom enclosure, cooling a 75W module without fans. Active cooling, with fans, slashes R_th for compact large heat sinks in data centers but adds noise and maintenance. Choose based on space, noise tolerance, and power density—hybrid systems often give the best of both worlds.

5. How do thermal interface materials (TIMs) affect large heat sink performance?

TIMs fill microscopic gaps between a component and the large heat sink, reducing thermal resistance (θ_CS). Early in my career, I used a low-quality TIM, causing a 10°C spike in a GPU test. Now, I opt for high-performance TIMs, like graphene-enhanced pastes, which can cut junction temperatures by up to 15°C in high-power large heat sink applications, such as LED modules.

6. Can CNC machining improve the design of large heat sinks?

Absolutely. CNC machining allows for intricate geometries and tight tolerances in large heat sinks, ideal for prototypes or mission-critical systems. In an aerospace project, I designed a CNC-machined large heat sink with integrated liquid cooling channels, boosting thermal performance by 20%. While costly, CNC machining is unmatched for custom large heat sinks in demanding applications like supercomputing or radar systems.

7. What are the trade-offs between liquid cooling and air cooling with large heat sinks?

Liquid cooling, using a large heat sink radiator, handles extreme heat fluxes (e.g., 500 W/cm² in supercomputers) but is complex and risks leaks. Air cooling with a large heat sink and fans is simpler and more common in data centers, but it’s noisier. In a liquid-cooled cluster I worked on, a CNC-machined large heat sink radiator kept temperatures below 70°C, but air cooling was sufficient for less demanding server racks.

Reference:

https://www.perplexity.ai/search/sustainable-manufacturing-ngPRpcaXShCjotg5IgNxOA;

https://en.wikipedia.org/wiki/Heat_sink;

https://www.energy.gov/energysaver/geothermal-heat-pumps;

Other Articles You Might Enjoy

- What Quality Control Measures Should Be in Place for CNC Machining of Copper Heat Sinks?

Understanding the Technical Challenges in CNC Machining Copper Heat Sinks Machining copper heat sinks presents several challenges due to the material’s softness, tendency to adhere to tools, and high thermal…

- Why Custom Aluminum Heat Sinks Are Best Made with CNC Machining

In today's advanced electronics and mechanical systems, aluminum heat sinks play a crucial role in thermal management, helping to dissipate heat and maintain optimal operating temperatures for components. As systems…

- How to Choose the Right CNC Machining Service for Precision Copper Heat Sinks?

Understanding the Technical Challenges in Machining Copper Heat Sinks Copper heat sinks are crucial in various electronic applications because of their superior thermal conductivity. However, this same property makes copper…

- How to Choose the Right CNC Machining Partner for Manufacturing Copper Heat Sinks?

What Technical Expertise Should You Look for in a CNC Machining Partner for Copper Heat Sinks? CNC machining of copper heat sinks presents unique technical challenges due to the material's…

- What Should Buyers Look for in a CNC Machining Company for Precision Copper Heat Sinks?

Understanding the Global Technical Challenges of Machining Copper Heat Sinks Global buyers seeking CNC machining suppliers for copper heat sinks face unique challenges due to variations in technical expertise, machinery…

- Why Custom Heatsink with CNC Machining Deliver Better Cooling

Introduction As someone who has worked closely with both CNC machining and thermal management solutions for high-performance electronics, I’ve seen firsthand how effective cooling systems can make or break a…