CNC Machining and the Importance of Tool Steel

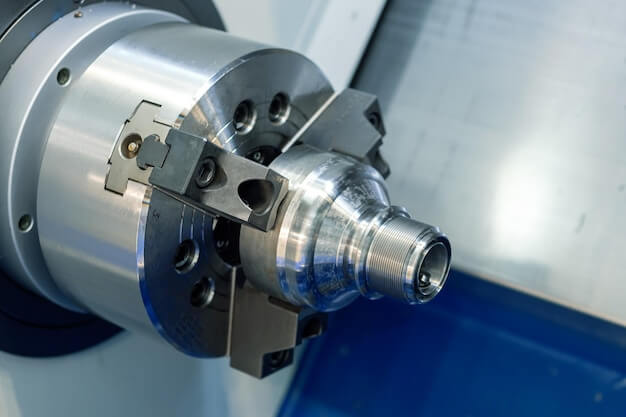

Computer Numerical Control, commonly referred to as CNC machining, is a high-precision manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It plays an instrumental role in creating complex three-dimensional shapes that would otherwise be impossible or highly tedious via manual manipulation. Within this advanced realm of production, tool steel emerges as a remarkably significant element for it forms the cutting mechanisms within these digitally directed machines.

- The A2 and D2 variants of tool steel particularly stand out due of their superior durability and performance levels, thus proving their indispensability within manufacturing processes.

A comparison between these two types becomes essential for manufacturers to ascertain which one suits best for their intended purposes and offers optimal returns on investment.

Understanding Tool Steels: D2 vs A2

In the vast arena of CNC machining, tool steels form a crucial part. To begin with, let’s focus on D2 tool steel which is preferred for its excellent abrasion resistance and high carbon content that amplifies hardness. For instance, this particular strength makes it ideal in manufacturing industrial cutting tools like punches and dies as they can maintain their sharp edges even in high stress.

-

D2 Tool Steel

D2 tool steel is essentially a high carbon, high chromium air-hardening steel known for its superior hardenability and abrasive wear resistance. It retains its stability even under extended exposure to high temperatures. Also, it holds up really well against distortion during heat treatment processes leading to better functional performance in various applications including long run stamping and forming dies, blanking reamers, hob cutters and shear blades among others.

-

A2 Tool Steel

Moving forward, we have another popular grade of tool steel – A2. Characterized by good machinability, its distinctive feature lies in higher toughness compared to other tool steels in spite of its relatively low levels of wear resistance. In real life application, consider how A2 steel would be an excellent choice for making injection moulds because these require high impact resistance without compromising on dimensional stability. This allows the moulds made from A2 steel to withstand the repeated pressure and temperature variations associated with plastic injection molding processes.

Manufacturing Process of D2 and A2 Tool Steel in CNC Machining

In the realm of Computer Numeric Control (CNC) machining, tool steels like D2 and A2 play integral roles. Let’s delve into how each is utilized.

D2 tool steel offers exceptional resistance to wear due to its higher carbon and chromium content. This makes it a suitable choice for long-production runs where durability is key. It’s commonly used in milling, turning, drilling, and grinding operations within CNC processes. Its superior hardness endows machined parts with high precision and excellent surface finish.

On the other hand, A2 tool steel has outstanding dimensional stability and good machinability properties. Thanks to its lower carbon content, it withstands distortions effectively during heat treatment, maintaining accuracy in dimensions more efficiently than D2. CNC machine operators frequently use A2 in applications requiring comprehensive heat treatments or ones that need strong resistance against deformations. The robust toughness ensures reliable performance even in aggressive machining conditions.

Durability Comparison: D2 vs. A2 Tool Steels

D2 and A2 tool steels are both popular choices in CNC machining due to their durability and performance. D2 steel offers high wear resistance and retention of hardness, making it suitable for applications requiring long tool life. On the other hand, A2 steel provides excellent toughness and impact resistance, making it ideal for applications involving heavy cutting forces and shock loads.

Performance Comparison: D2 vs. A2 Tool Steels

In an analytical comparison between D2 and A2 tool steels, the performance attributes of each reveal distinct advantages. The D2 steel is renowned for its exceptional wear resistance due to its high chromium content, which imbues it with superior hardness and edge retention capabilities.

- D2 Steel has a rockwell hardness range of 55-62 HRC, making it distinctly harder than other steel types

- This steel type also exhibits remarkable stability, retaining its toughness even in extreme temperatures such as -20 degrees Celsius

On the other hand, A2 tool steel holds prominence for its impressive dimensional stability. This ability makes it a preferred choice when precision applications are paramount. It is less likely to shrink or expand under different temperature variations, therefore maintaining tighter tolerances during heat treatment processes. Moreover, while A2 may not offer the same degree of hardness as D2, it compensates by its excellent combination of good wear resistance and robustness.

- A2’s Rockwell hardness typically falls within a 57-62 HRC range, slightly softer compared to D2 but still remarkably hard and durable

- The key strength lies in its superb impact resistance which yields longer tool life.

“

D2 vs. A2 Tool Steel in CNC Machining: Pros and Cons

The use of D2 tool steel in CNC machining offers significant advantages, mainly due to its exceptional wear resistance and hardness qualities. It usually stands out for its ability to maintain sharp edges even under intense operations that can significantly extend the lifespan of tools. However, there is a downside – it tends to be challenging to machine and requires more effort to shape or form. Furthermore, it has somewhat reduced toughness compared to other types of tooling materials which could make it less durable in heavy-duty applications.

On the other hand, A2 tool steel provides a balanced combination of good wear resistance, excellent dimensional stability, and some degree of toughness. This allows for easy machinability and makes it suitable for a range of general-purpose tasks. Nevertheless, while A2 betters than D2 on machinability aspect, it didn’t offer the same level of wear resistance as D2, which might mean shorter tool life in high-wear situations. Additionally, it may be slightly costlier than alternative options, adding expense to your overall production budget.

“

Conclusion

In the exploration of tool steel in CNC machining, the focus has been on comparing the durability and performance between D2 and A2. An understanding of their unique properties can guide one’s decision-making process based on specific needs. While both types exhibit exceptional shock resisting characteristics, heat treatment processes offer D2 a slight edge in terms of hardness as against A2.

However, It would be imprudent to overlook the impressively high wear resistance offered by A2 steel, emphasizing its suitability for longer-term application scenarios. There may not be an overall winner considering the variability of projects and their requirements; thus:

- D2 could be an ideal fit in scenarios where optimal hardness is critical over more extended periods,

- A2 would be favorable under conditions requiring exceptional toughness and phenomenal dimensional stability after undergoing heat treatment.

To conclude, the challenge lies in analyzing your specific project demands and aligning them with these tool steels’ strengths- thereby optimizing for best results.

Other Articles You Might Enjoy

- Exploring Bead Blasting in CNC Machining(cnc machining services china Nicole)

Bead blasting is a process used extensively in the world of computer numerical control (CNC) machining. A standard part of many businesses, bead blasting enriches various products that we use…

- Unveiling the Brilliance of Bead Blasting in CNC Machining(cnc machining services china Elijah)

Bead blasting is an outstanding technique used extensively in most industries that demand a high-quality finish, encompassing those as diverse as auto manufacturing to aerospace. This article aims to shed…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…