In the dynamic world of CNC machining, the ability to safely and efficiently interrupt a machining process is crucial. There are several methods available to operators to pause or stop a program mid-operation. Understanding and utilizing these methods can significantly enhance both safety and productivity. Let’s explore the key interrupt methods in CNC machining: single block execution, feed hold, and emergency stop.

Single Block Execution

By using the single block execution mode, operators can carefully step through the program. This method allows for close observation of each action, making it easier to catch errors or issues before they affect the entire process. The single block execution button on the control panel activates this mode, and each press of the cycle start button executes the next block in the sequence. This method can also be combined with other settings to enhance program verification.

Single block execution is a valuable tool for program verification and debugging. In this mode, the CNC machine executes one program segment, or block, at a time. Each block is a line of code that commands a specific action. Normally, CNC machines run in continuous mode, executing one block after another seamlessly. This continuous operation is essential for production efficiency but isn’t always ideal for troubleshooting or verifying new programs.

Feed Hold

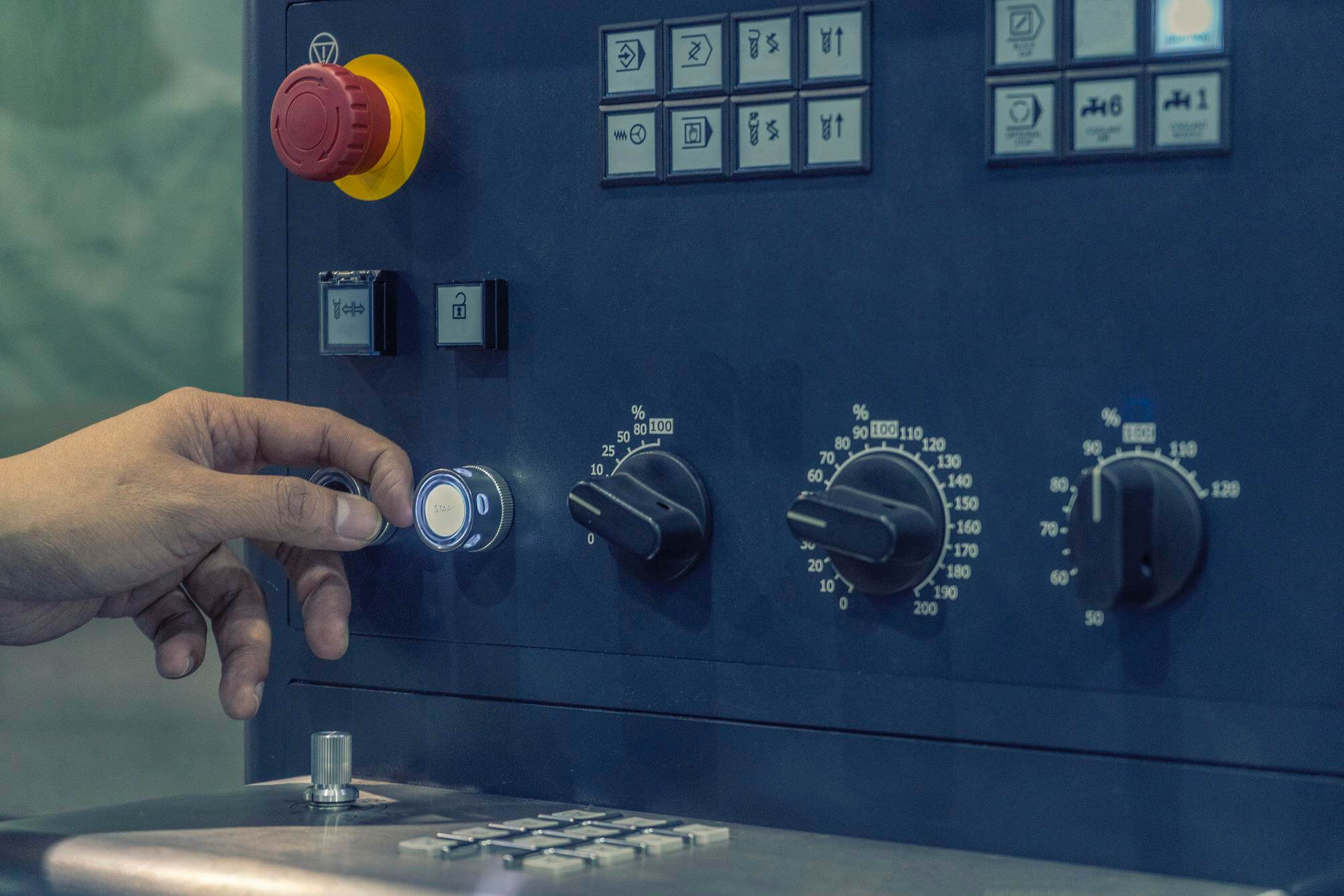

Feed hold is another critical function, especially useful during setup or when machining the first part in a batch. The feed hold button is typically located near the cycle start button on the control panel. When pressed, it immediately halts the movement of all axes, pausing the machining process without altering any program values. This function is particularly handy for making quick checks or adjustments.

Certain machining operations, such as threading or tapping, may restrict or disable the feed hold function. When activated, the feed hold button usually lights up, indicating that the machine is in a paused state. It’s important to note that while the feed hold is active, the machine’s motion is paused, but the program remains unchanged. CNC programmers can also choose to ignore feed hold in the program for specific operations where it might cause issues.

Emergency Stop

Every CNC machine is equipped with an emergency stop button, a prominent red mushroom-shaped button that is easy to access. This button immediately halts all machine movements and cuts power to the machine, requiring a restart to resume operations. The emergency stop is a mandatory safety feature designed to protect both the operator and the machine.

While effective, the emergency stop should be used as a last resort. It’s not always the best or only way to halt operations, as it can cause abrupt stops that might not be ideal for the machine’s components. Modern control systems offer other features to prevent collisions between the cutting tool and the workpiece or fixture, such as the feed hold. However, in situations where time is critical, and other methods would take too long, the emergency stop is essential.

It’s also worth noting that the effect of the emergency stop can vary depending on the machine’s current action. For example, bringing a spinning spindle to a complete stop might take a moment, even after the emergency stop is activated. Therefore, it’s crucial to remain calm and not panic in an emergency, using the stop button as designed.

The ability to interrupt CNC machining processes safely and efficiently is a vital skill for operators. By understanding and effectively using single block execution, feed hold, and emergency stop, operators can enhance both the safety and efficiency of their machining operations. These methods provide essential tools for maintaining control over the machining process, ensuring that both the machine and the operator are protected at all times.

Other Articles You Might Enjoy

- Tapping Methods in CNC Machining

Classification and Characteristics of Tapping in CNC Machining Tapping, using taps to machine threaded holes, is the most commonly used method for creating threaded holes. It is mainly suitable for…

- The Future of Medical Device Manufacturing: CNC Machined Stainless Steel

Introduction to Medical Device Manufacturing Medical device manufacturing is a crucial sector in the healthcare industry, powering a myriad of medical procedures and treatments worldwide. This field involves the design,…

- Precision CNC Machining for High-End Audio Equipment

Precision CNC Machining in High-End Audio Equipment Manufacturing Precision Computer Numerical Control (CNC) machining refers to a highly-advanced technology where computer-generated codes are used to operate factory machinery and tools.…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Custom CNC Machining: Tailoring Solutions to Unique Engineering Challenges?

Introduction to Custom CNC Machining In the manufacturing world, innovations continually emerge and challenge traditional production methodologies. A significant game-changer has been Computer Numerical Control (CNC) machining — a process…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…