Introduction: Overview of Cobalt Chrome Alloys in Medical Implant Manufacturing

Cobalt chrome alloys are extensively involved in the production of medical device implants due to their superior characteristics such as high hardness, wear resistance and excellent biocompatibility. This alloy constitutes primarily of cobalt and chromium, with smaller amounts of elements such as molybdenum which offer increased tensile strength and corrosion resistance. These attributes make it an ideal choice for products like hip and knee replacements where high stress situations occur frequently.

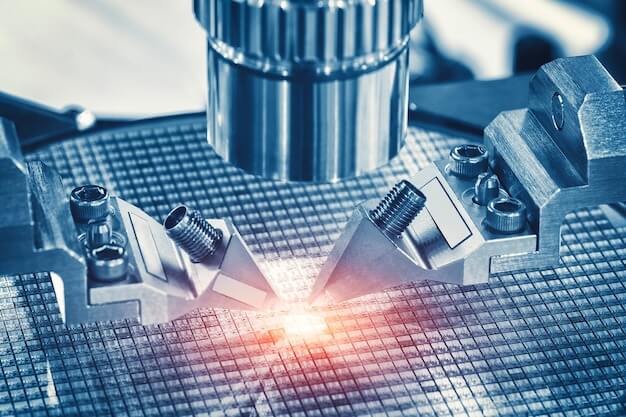

In manufacturing these medical implants, CNC (Computer Numerical Control) machining comes into action. It is a modern method that supports precision in creating complex shapes necessary for the various types of implants. The intricate process involves a series of controlled material-removal operations aided by computer programming. Thereby making sure each product adheres to exact specifications without variation, minimizing risks linked to faulty implants. Though this technique provides unmatched accuracy, understanding the properties of cobalt-chrome alloy is crucial because its hardness often makes the machining process more challenging than working with softer materials.

- Tensile Strength: Cobalt chrome has exceedingly high tensile strength, thus ensuring long-term stability of the implant.

- Corrosion Resistance: Exceptional corrosion resistance ensures durability and safety within the body’s harsh environment.

- Wear Resistance: The capacity to withstand constant friction and strong forces common in joints makes it perfect for joint replacement implants.

- Biocompatibility: Its well-tolerated presence in biological systems aids in avoiding allergic reactions or material rejection.

Understanding Medical Implants

In the field of medical technology, medical implants stand as a significant development. Essentially, medical implants are devices or tissues placed inside or on the surface of the body to restore function, support an inadequacy, or enhance an aspect of the human anatomy’s structure or functionality. These include a vast range of implanted items, such as hip replacements, heart valves, pacemakers, and even prosthetic limbs.

The importance and benefits of these innovations in healthcare cannot be underestimated. Medical implants significantly contribute to patient wellbeing by replacing lost functions, thereby enhancing the quality of life for many patients. For instance, a cochlear implant can help someone with profound hearing loss to hear again, while a knee replacement unit can enable a previously immobile person to walk unaided. This substantial enhancement to people’s lives emphasizes the undeniable value that medical implants bring within the healthcare industry.

Why Cobalt Chrome Alloys?

Cobalt chrome alloys are gaining increased significance in the field of medical implant manufacturing, due to their unique properties and advantages. These high-performance alloys principally consist of cobalt, chromium, and molybdenum, known for their exceptional strength, superior wear resistance, and high corrosion resistance.

- Strength: Cobalt-chrome alloys demonstrate extraordinary mechanical strength even under extreme conditions which closely replicates the performance characteristics of human bone. This makes it an excellent choice for various implants such as joint replacements.

- Wear Resistance: Implants endure constant friction and abrasion within the human body. The impressive wear resistance of cobalt-chrome alloys potentially contributes to prolonging the lifespan of implants thereby reducing the need for replacement surgeries.

- Corrosion Resistance: Implants are exposed to the corrosive environment inside the human body. Hence, materials used for this purpose must resist pitting and metal leaching while maintaining biocompatibility. Owing to its high chromium concentrations, cobalt chrome alloys meet these stringent requirements with ease.

In conclusion, cobalt chrome’s distinct physiochemical properties, coupled with its biological compatibility make it highly suitable in the complex and demanding arena of medical implant manufacture.

Understanding the CNC Machining Process with Cobalt-Chrome Alloys

Cobalt-chrome alloys play a crucial role in the CNC machining process, offering exceptional strength and corrosion resistance. The high melting point and biocompatibility of cobalt-chrome alloys make them ideal for medical and aerospace applications. When considering CNC machining with cobalt-chrome alloys, it’s essential to partner with a online CNC service provider that specializes in precision machining to ensure the highest quality and accuracy of the final products.

Considerations for CNC Machining of Cobalt-Chrome Alloys

In the manufacturing process of medical implants using cobalt-chrome alloys, it is essential to take into account a variety of considerations when utilizing Computer Numerical Control (CNC) machining. Firstly, one challenge commonly encountered during this operation is the high hardness and heat resilience of these alloys which, can cause tool wear and deformation if not carefully managed. To deal with this, professionals must consider adjusting cutting speeds or even employing different tool materials that can better tolerate the process parameters.

- Durability of Tools: For efficient production, checking and ensuring the durability of the machining tools in order to withstand the extreme conditions related to cobalt-chrome alloy processing is vital.

- Quality Assurance: It’s also paramount to put quality assurance measures in place because any defects, however minute they may seem to be, could lead to severe consequences for end-users such as patients who rely on the accuracy of these medical implants.

- Cooling Systems: Moreover, maintaining optimal cooling systems, able to rapidly dissipate heat generated during machining, is another key factor for effective production. This helps in preventing thermal-induced deformities that can compromise implant functionality.

A balance between all these considerations will result in efficiency and efficacy in the production process while ensuring optimized yields within given cost boundaries.

Successful Application of Cobalt Chrome Alloy in Medical Implants

In the medical industry, specific real-life examples have underlined the successful application of cobalt chrome alloy through CNC machining for creating viable medical implants. For instance, hip replacements commonly utilize cobalt chrome alloys because their robust strength, wear resistance and biocompatibility render them ideal materials for these weight-bearing applications. A patient who received such a hip implant observed notable improvement in mobility and decrease in pain post-operation; highlighting the significant positive impact and benefits to patients’ lives after receiving implants made from this material.

Benefits can be summarised as:

- Mobility Enhancement: Patients could walk better and engage in physical activities that were difficult pre-replacement surgery.

- Pain Reduction: Recipients experienced substantial reduction in chronic joint pains tied with existing skeletal issues.

- Improved Quality of Life: With improved mobility, lesser pain, and enhanced self-dependency, there was an overall upliftment in life quality.

This example not only demonstrates technical usefulness of Cobalt Chrome Alloy but also its human-centric impact in advancing health and wellness solutions.

Conclusion

In conclusion, the application of cobalt chrome alloys in medical implant manufacturing by CNC machines has proven to be a pivotal innovation. These alloys boast desirable characteristics such as excellent wear resistance, biocompatibility, and superior strength-to-weight ratio, enabling them to replicate vital functions excellently.

The strategic advantage endowed by the use of high-precision CNC machining in this context cannot be overstated either; ensuring highly accurate production of specific parts down to minute details, which then guarantees improved patient comfort post-application. Predictably, this technology will continue being exploited extensively at an increasing pace given its inherent efficiency and effectiveness benefits.

Looking ahead,

- The future holds immense potential for optimizing these processes even further with advancements in AI and machine learning technologies likely to bring about unprecedented accuracy levels and design possibilities.

- Futuristic applications may also accommodate customization options per individual patients’ unique requirements – potentially revolutionizing personal healthcare delivery.

- Last but not least, the possibility of integrating sustainability considerations into these processes offer another exciting dimension to explore, especially regarding recyclability or reusability aspects of cobalt chrome alloys.

Other Articles You Might Enjoy

- Innovative CNC Machining for Custom Medical Instruments

Innovative CNC Machining for Custom Medical Instruments Computer Numeric Control (CNC) machining is an innovative automated process that utilizes computer software to control machine tools. The use of CNC machines…

- Aluminum Parts Machining: CNC Techniques for Precision and Efficiency

Introduction to Aluminum Parts Machining and CNC Techniques In the manufacturing industry, the machining of aluminum parts plays a crucial role for its effortless machinability which makes it an ideal…

- Tool Steel Grades in CNC Machining: Which One Should You Choose for Durability?

Introduction to Tool Steel in CNC Machining In the realm of CNC (Computer Numerical Control) machining, tool steel reigns supreme due to its exceptional durability and versatility. As a broad…