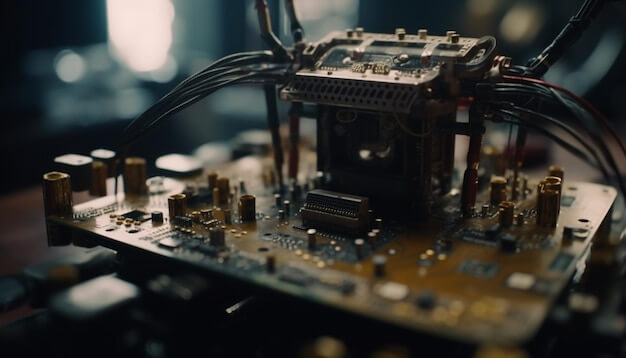

1. Introduction: The Digital Frontier of CNC Machining

In this introductory section, we embark on a journey into the digital frontier of CNC machining, specifically focusing on the emergence and impact of CNC online services in China. It sets the stage for understanding how these services are revolutionizing the traditional landscape of manufacturing.

2. The Technological Tapestry: Understanding CNC Online Services in China

Delving into the technological intricacies, this section provides a comprehensive understanding of CNC online services in China. It explores the core features, digital platforms, and advanced technologies that form the tapestry of these services, allowing manufacturers to navigate the digital realm with precision.

3. Advantages of CNC Online Services: A Roadmap to Manufacturing Success

This pivotal section outlines the key advantages offered by CNC online services in China, acting as a roadmap for manufacturers aiming for excellence. Utilizing a structured list format, key advantages are highlighted:

- Global Connectivity: Exploring how CNC online services provide manufacturers with global connectivity, fostering collaboration and market expansion.

- Real-time Data Monitoring: Discussing the significance of real-time monitoring capabilities in optimizing manufacturing processes.

- Cost-Efficiency: Detailing how CNC online services contribute to cost savings through streamlined workflows and reduced downtime.

- Scalability and Flexibility: Highlighting the scalability and flexibility offered by these services to adapt to changing production demands.

4. Real-world Applications: Success Stories in CNC Online Service Integration

This section brings theory into practice by showcasing real-world applications and success stories where CNC online services in China have played a pivotal role. Through detailed narratives, readers gain insights into how businesses across industries have successfully navigated the path to excellence by integrating CNC online services into their manufacturing processes.

5. Challenges and Future Trends: Steering Towards a Digital Manufacturing Horizon

Concluding the article, we explore the challenges faced by manufacturers in navigating excellence with CNC online services in China. Additionally, we discuss future trends, innovations, and the evolving landscape of digital manufacturing, providing a glimpse into what lies ahead.

By the end of this comprehensive exploration, readers will have gained a profound understanding of how CNC online services in China are not just a technological tool but a strategic compass, guiding manufacturers towards excellence in the digital era of CNC machining.

Related Posts

- High-Precision CNC Machining for Advanced Robotics Components

Introduction to High-Precision CNC Machining The realm of advanced robotics component manufacturing has seen remarkable advancements through high-precision CNC (Computer Numerical Control) machining. Typically, high-precision CNC machining is a process…

- Exploring Bead Blasting in CNC Machining(cnc machining services china Nicole)

Bead blasting is a process used extensively in the world of computer numerical control (CNC) machining. A standard part of many businesses, bead blasting enriches various products that we use…

- Tool Steel in CNC Machining: D2 vs. A2 - A Comparison of Durability and Performance

CNC Machining and the Importance of Tool Steel Computer Numerical Control, commonly referred to as CNC machining, is a high-precision manufacturing process where pre-programmed computer software dictates the movement of…