Introduction to High-Precision CNC Machining

The realm of advanced robotics component manufacturing has seen remarkable advancements through high-precision CNC (Computer Numerical Control) machining. Typically, high-precision CNC machining is a process that involves the automated control of machine tools via programmed instructions – ensuring superior accuracy and consistency in production. The significance of this precise machining method lies in its ability to render exceptionally detailed components vital for leading-edge robotic technologies.

- Need for precision: Robotic applications often require intricate parts with exact tolerances, demanding an extraordinary level of precision unattainable through manual methods.”

- Importance in Manufacturing: In scenarios where every micron matters, such as surgical robots or delicate inspection bots, high-precision CNC machines play an indispensable role by fabricating precise parts consistently, thereby reducing errors and optimising performance.

This highlights how integral high-precision CNC machining is in producing modern-day robotic equipment that can efficiently perform complex tasks that enhance our daily life.

Advanced Robotic Components and Their Precision Needs

Advanced robotics components refer to the intricate parts that make up a high-tech robotic system. These can range from sophisticated sensors, motorized joints, tiny circuit boards, or more complex parts like an entire robotic arm. Each of these pieces needs to be produced with utmost precision because each part functions together in a precise manner to enable the robot’s successful operation.

Precision in creating these components is non-negotiable; it ensures accuracy, consistency, and reliability in the functioning of the robotic unit. For instance, inaccuracies in manufacturing could lead to faulty mechanisms, reduced efficiency, and even systems failure. Undeniably, precision allows for seamless interoperability among various components, improving the overall robustness and resilience of the robot.

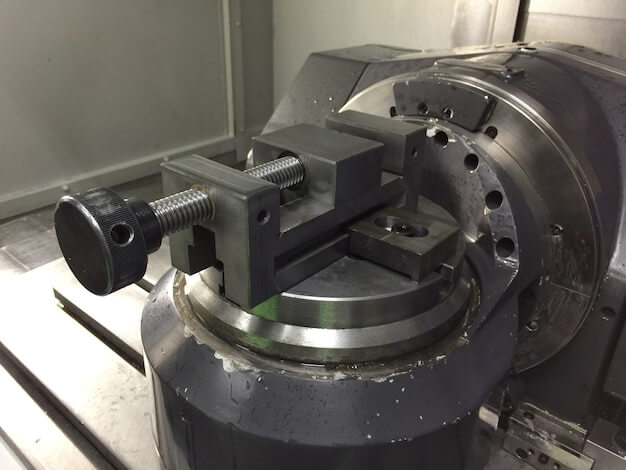

The production process of an advanced robotic arm offers a classic example of using high-precision CNC machining. This process involves designing intricate components, such as wrist joints, finger elements, and movement actuators. All these key parts require absolute preciseness to ensure smooth operation. Features like

- Accuracy: to maintain exact dimensions during creation,

- Tolerance: to cater for slight variations without interfering with performance,

- Consistency: to duplicate similar units overtime without degradation in their quality,

illustrate the importance of highly precise machinery in erection of advanced robotic components.

How High-Precision CNC Machining Works in Advanced Robotics:

- High-precision CNC machining plays a crucial role in the production of advanced robotics components, ensuring precise, fast, and constant part quality.

- This article provides insights into the application of high-precision CNC machining in advanced robotics components. online CNC service

- The process involves the use of CAD and CAM software to create a design and translate it into manufacturing instructions for the CNC equipment. Skilled machinists then load the instructions into the machine, which automatically performs actions like cutting, milling, turning, and electrical discharge machining to achieve the final product.

Benefits of High-Precision CNC Machining in Advanced Robotics

In the realm of advanced robotics, high-precision CNC (Computer Numerical Control) machining brings several notable benefits to the table. An essential advantage lies within product improvement, where CNC machining offers excellent repeatability and accuracy levels. This ensures that every single robotic component manufactured is exactly alike with sub-millimetric precision, resulting in higher-quality robot parts and improved performance.

Besides enhancing part quality, high-precision CNC machining substantially optimizes efficiency by automating the complex production processes, which had been manually intensive before. Henceforth, a CNC machine can operate round the clock with minimal human supervision, thus saving labor costs and time.

Moreover, it is instrumental in reducing waste as it abides by green manufacturing policies. Given its precise control, material wastage commonly seen in traditional methods is significantly minimized. For instance, when fabricating metal components for a robot arm or other intricate parts, the exact amount of necessary material is used, curtailing excessive raw material consumption and environmental footprint.

Challenges Faced with High-Precision CNC Machining

In the realm of high-precision CNC machining, several obstacles commonly arise that impede efficient fabrication of advanced robotics components. A primary challenge faced is the substantial cost affiliated with acquisition, operation, and maintenance of sophisticated machineries. Moreover, achieving pinpoint accuracy demands highly-skilled operators in combination with state-of-the-art machines, contributing both to increased labor costs and technical complexities.

A significant technical predicament often manifests itself during the actual machining process. For instance, whilst attempting to craft a partially-finished gear component for a precision robot arm, a minute programming error led to incorrect spindle speed causing an unacceptable level of discrepancy in the end product. The hiccup resulted in production downtime, further escalating manufacturing expenses while emphasizing a critical need for flawless integration between humans and machines within the intricate maze of high-precision CNC machining.

Other Articles You Might Enjoy

- Navigating Excellence with CNC Machining Online Services in China

1. Introduction: The Digital Frontier of CNC Machining In this introductory section, we embark on a journey into the digital frontier of CNC machining, specifically focusing on the emergence and…

- Exploring Bead Blasting in CNC Machining(cnc machining services china Nicole)

Bead blasting is a process used extensively in the world of computer numerical control (CNC) machining. A standard part of many businesses, bead blasting enriches various products that we use…

- Tool Steel in CNC Machining: D2 vs. A2 - A Comparison of Durability and Performance

CNC Machining and the Importance of Tool Steel Computer Numerical Control, commonly referred to as CNC machining, is a high-precision manufacturing process where pre-programmed computer software dictates the movement of…