Introduction to Sheet Metal CNC Machining

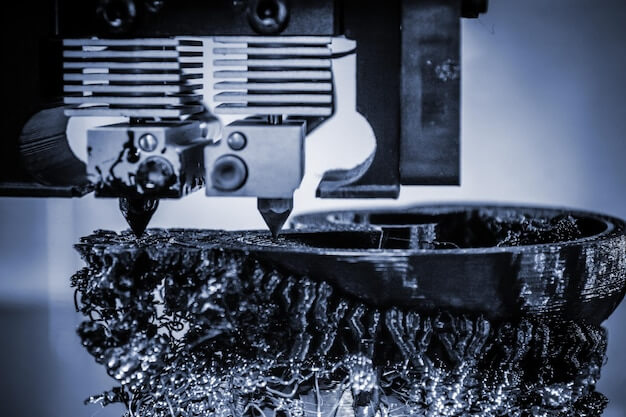

CNC, or Computer Numerical Control machining, is a manufacturing process in which pre-programmed computer software dictates the movement of factory machinery and tools. This technology drastically speeds up production and enhances precision in industries such as aerospace, automotive, and electronics.

Sheet Metal, on the other hand, plays an integral role in CNC machining due to its malleability, durability, and versatility. It can be easily manipulated into various shapes quite precisely with the aid of CNC machines while maintaining structural integrity. As sheet metal also tends to be lightweight yet robust, it makes for efficient and cost-effective processing.

- Malleability: The ability of sheet metal to be shaped by pressure without breaking or cracking allows intricate designs with high accuracy.

- Durability: Despite being subjected to intense pressure during the forming process, sheet metal maintains its strength and resists wear and tear.

- Versatility: Its compatibility with different grades and types of metal- from stainless steel to aluminum, brass, or bronze- offers numerous application possibilities across diverse sectors.

Understanding Sheet Metal CNC Machining Techniques

Sheet metal CNC machining techniques encompass a range of processes, including:

- Online CNC service

- Precision Machining Service

- Laser cutting

- Plasma cutting

- Metal bending

Applications of Sheet Metal CNC Machining

The application of sheet metal CNC machining permeates an assortment of industries, contributing significantly to everyday life. Major sectors that leverage this high-precision process span from the automotive industry to aerospace engineering among many others. These applications impact our day-to-day living in a variety of ways.

For instance, in the Automotive Industry, CNC machining is instrumental in the production of car parts such as the engine components and body parts, ensuring precise dimensions for better efficiency and safety.

In the Aerospace industry, it’s equally indispensable – parts like turbine blades, fuselage sections, and antennas are all made via CNC machining, allowing aircrafts to withstand extreme conditions while maintaining optimal performance.

Another example would be the Appliance industry, where CNC machining helps build parts for domestic appliances we use daily – refrigerators, washing machines or microwaves. A specific example being a refrigerator door handle which requires precision and durability; properties afforded by CNC machining techniques.

The above are just few examples demonstrating how integral sheet metal CNC machining is to various fields and subsequently our daily lives.

Benefits of Sheet Metal CNC Machining

The efficiency, accuracy and cost-effectiveness of sheet metal Computer Numerical Control (CNC) machining contribute to its immense benefit in manufacturing processes. Primarily, the increased productivity due to CNC machining is notable; for instance, Zhongshan City Ming Bai Hardware Products Co., Ltd reported a 30% increase in output per hour by incorporating CNC machines into their production line. This elevated efficiency results from the fact that CNC machines can run continuously 24 hours a day without requiring breaks.

- This constant operation maximises productivity while minimising manual labor costs.

- The precision level offered by CNC machining is also superior. The automated nature of these machines reduces human error probability considerably. Hence, they deliver finely-tuned pieces with intricate details consistently.

- CNC machining has proven more cost-effective compared to traditional methods. With reduced labor cost, lower waste levels due to high accuracy, and lessened need for rework or repair, significant financial savings are realized.

Conclusion

In summation, Sheet Metal CNC Machining encapsulates an impressive array of techniques and applications, playing a pivotal role in several branches of the industrial field including automotive, construction, ICT, aerospace and more. This technology heralds numerous benefits such as heightened precision, efficiency, consistency, versatility, and reduced labor costs. With constant advancements happening within this arena, we foresee an exponential evolution in sheet metal CNC machining methodology and its potential. The continual development of CAD/CAM software anticipates improving the design and manufacturing process even further, leading to complex constructions achieving faster turnovers and reduced wastage.

Other Articles You Might Enjoy

- Unlocking New Possibilities in CNC Machined Titanium Medical Devices

Introduction to CNC Machined Titanium Medical Devices The prevalence of CNC machined titanium medical devices in the healthcare sector demonstrates their immense significance and usefulness. This technology furnishes an essential…

- CNC Aluminum Machining Services: Advanced Techniques for Perfect Parts

CNC Aluminum Machining Services In the current manufacturing landscape, CNC aluminum machining services play a pivotal role. CNC which simply translates to 'Computer Numerical Control', is an advanced technique used…

- Hastelloy vs. Stainless Steel in Chemical Processing Equipment: CNC Machining Perspectives?

Hastelloy vs. Stainless Steel in Chemical Processing Equipment: An Introduction In the realm of chemical processing equipment, two commonly used materials include Hastelloy and stainless steel. Hastelloy, a reputed superalloy…