Role of CNC Machining in Manufacturing and Future Smart Cities

CNC (Computer Numerical Control) machining is a pivotal aspect of the modern manufacturing industry that contributes substantially to its efficiency, precision and consistency. As an automated process where computer-software governs the movement of factory tools and machinery, it fosters production accuracy and streamlines operations significantly.

The vital function of CNC machining extends beyond the realm of the traditional industry, hinting at significant interrelations with future smart cities as well. With rapid urbanization coupled with the push for intelligent systems, the scope for intricately crafted components required for sustainable infrastructure and advanced technologies amplifies further. Consequently, the role of CNC machining intensifies, augmenting the core capabilities necessary for morphing ordinary cities into ‘Smart’ ones. This transformative influence can be distinctly noted within:

- Sustainable Infrastructure Development: CNC machining’s precise outcomes reduce waste and promote efficient use of raw materials enhancing sustainability.

- Advanced Communication Systems: Enabling the creation of complex parts needed for cutting-edge communication devices linking every component of a smart city.

Understanding the Basics and Applications of CNC Machining:

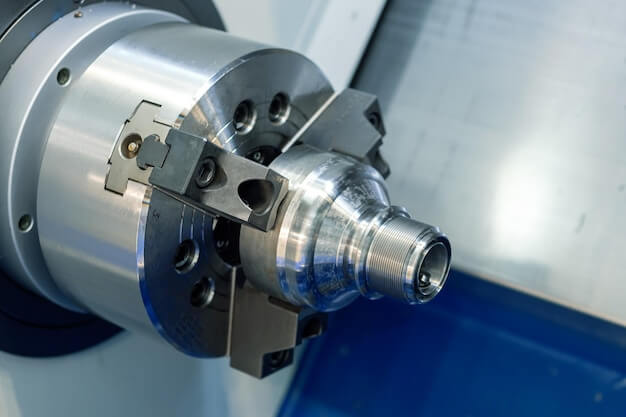

- Step 1: CNC machining is a subtractive manufacturing process that uses computerized machine tools to create custom-designed parts.

- Step 2: The process involves using software-controlled milling, turning, or EDM machines to remove layers of material from a workpiece, resulting in precise and tailored components.

- Step 3: To delve deeper into the applications and intricacies of CNC machining, consider exploring resources such as RapidDirect’s knowledge base for valuable insights and information.

The Role of CNC Machining in Today’s Manufacturing Era

In our current manufacturing climate, Computer Numerical Control (CNC) machining plays a prevalent and significant role. By taking intricate designs created by software and turning them into reality with extreme precision, CNC machining has revolutionized modern manufacturing processes. It lends a level of automation and consistency that was unattainable with traditional techniques, driving efficiency up while keeping costs controlled.

- A notable example of its usage can be observed in the automobile industry – CNC machines are used for producing complex engine parts and other numerous car components seamlessly.

- Furthermore, these machines have transformed the aerospace sector as well where high precision and zero error tolerance is paramount. They are utilized to manufacture everything from turbine parts to structural aircraft elements.

- In addition, the medical device industry also heavily relies on CNC machining for producing highly accurate, medical-grade components like implants or surgical instruments.

CNC machining showcases how technical advancements can greatly enhance manufacturing capabilities across varied industries, fortifying both quality control

and overall productivity.

Smart Cities Explained: Definition, Features and Examples

Essentially, a ‘smart city’ is one that leverages technology and data to improve the quality of life for its citizens, enhance sustainability, and streamline urban services. Key smart city features include IoT-enabled devices, integrated communication systems, sensors, AI-powered analytics, and advanced manufacturing techniques such as CNC machining. These cities comprehensively use information and digitization in citizen engagement, infrastructure maintenance, transportation management, and resource allocation.

A prime example of a smart city globally utilizing advanced manufacturing techniques is Singapore. The city-state invests heavily in digital infrastructure and automation technology with an emphasis on CNC Machining. Other examples are Barcelona, which utilizes IoT sensors for parking, lighting, and waste management; Seattle making extensive use of Big Data for traffic control; and Copenhagen, deploying sensor-based solutions for environment monitoring. Together, these global prototypes represent different facets of how smart cities can optimize their functioning, service delivery and overall quality of living by leveraging various technological advancements.

]

The Evolution of CNC Machining Towards the Advancement of Smart Cities

As urban centers globally embrace the concept of smart cities, Computer Numerical Control (CNC) machining is evolving to cater to this digitized and interconnected infrastructure. This evolution is demonstrated in innovative technologies and developments within CNC machining that promise to enhance the functionality and ‘smartness’ of future cities. For instance, the integration of Artificial Intelligence (AI) into CNC systems is allowing for predictive maintenance, reduced downtime, and more efficiency in manufacturing components necessary for cities’ digital infrastructures.

- Predictive Maintenance: By incorporating AI, CNC machines can predict potential failures, thus reducing unexpected downtimes and ensuring an uninterrupted supply of manufactured components for the city’s needs.

- Increased Efficiency: The use of AI also allows these machines to operate at optimum capacity round the clock, producing high-quality products efficiently which fast tracks the development of smart components.

In summary, the continuous technological advancements within CNC machining are imperative to meet the complex demands of developing smarter and more connected cities, propelling us towards a sustainable future.

Challenges and Solutions in Integrating CNC Machining into Smart City Model

The integration of Computer Numerical Control (CNC) machining into the smart city model poses several challenges. A common issue is ensuring seamless communication between different machines and devices, achieving synchronization in real-time operations. The multifaceted challenge also includes addressing gaps in standards for data exchange protocols to ensure compatibility across various machine models.

- An effective strategy could be adopting scalable IoT solutions optimized for industry needs. This would facilitate better machine-to-machine interaction, leading to enhanced performance and overall effectiveness of the CNC systems within a smart city ecosystem.

- In order to address data protocol standardization, implementing universal communication architectures can be beneficial.

Moreover, training professionals with comprehensive understanding of both cutting-edge CNC technology and its interface with existing urban infrastructures, proves crucial in truly transforming CNC machining for a smarter future.

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Breaking Barriers in CNC Machined Aerospace Structures

Introduction: CNC Machining in Aerospace Structures In the aerospace industry, accuracy, reliability and efficiency are paramount. To maintain these standards, modern day aerospace manufacturing heavily leans on Computer Numerical Control…