Introduction (Brief)

Plastic washers often seem like simple, minor parts. I used to think the same—until I faced an issue where standard off-the-shelf plastic washers just couldn’t solve my problem. My project demanded specific thicknesses, unique diameters, and a material tough enough for extreme conditions. That’s when I first discovered the power of CNC machining.

If you’re struggling like I once did, with plastic washers that standard suppliers just can’t deliver, keep reading. CNC machining can completely solve your problem—and I’ll explain exactly how.

Industry Applications of Plastic Washers

Electronics and Insulation

When I first started working with electronics, plastic washers were among the components I underestimated most. They seemed trivial—small, simple parts—but I quickly learned how critical they could be. During one particular assembly project, our electronics began to malfunction due to tiny metallic washers creating inadvertent shorts. Plastic washers quickly became our solution, specifically designed to electrically insulate fasteners and sensitive components.

In one incident, the standard plastic washers we initially used were too thin, causing cracks and failure under pressure. Off-the-shelf washers simply couldn’t hold up under the specific stresses of our application. We resolved this by opting for CNC-machined plastic washers with exact thickness and diameter tolerances. CNC machining gave us the flexibility to choose materials like POM (Delrin), known for its excellent insulating properties, durability, and mechanical strength. I realized then how crucial the precision and flexibility of CNC machining could be.

Medical Equipment

Medical equipment demands the highest levels of precision and reliability. Early in my career, I participated in a project designing washers for surgical instruments. Initially, we chose injection-molded washers because they seemed cost-effective. Unfortunately, these standard washers repeatedly failed under sterilization processes involving high-pressure steam and chemical baths. Each failure meant significant delays, costs, and frustration.

Switching to CNC machining allowed us to use advanced medical-grade plastics like PEEK and PTFE. Both these materials withstand extreme sterilization cycles and aggressive disinfectants without losing structural integrity. The flexibility in design that CNC provided was unmatched. Each washer could be precisely tailored in size, thickness, and shape, vastly improving reliability and patient safety. After switching, we reduced failure rates to nearly zero, saving significant resources long-term.

Automotive Assemblies

The automotive sector frequently deals with complex mechanical stresses and environmental conditions, from engine heat to road vibrations and corrosion risks. I once visited a manufacturing plant dealing with recurring issues caused by metal washers corroding and degrading surrounding components. The result was a substantial rise in warranty claims and repairs.

Replacing those metal washers with CNC-machined plastic washers dramatically solved these corrosion and wear issues. Materials like Nylon and UHMWPE provided exceptional vibration damping and corrosion resistance. The ability to precisely customize washer dimensions allowed us to retrofit existing assemblies without major design changes. Over several months, warranty claims decreased sharply, demonstrating the immense practical value CNC plastic washers provided.

Aerospace and Aviation

Aerospace demands zero-compromise reliability—there’s simply no margin for error. Early on, I assumed aerospace components exclusively relied on metal, but during a visit to an aerospace component supplier, I witnessed firsthand how advanced plastics were reshaping expectations. Plastic washers made from materials like PTFE and PEEK offered exceptional temperature resistance, lightweight advantages, and critical chemical resistance.

We once faced challenges fitting washers into tightly designed assemblies where off-the-shelf products were unsuitable. Standard washers varied slightly, enough to compromise assembly integrity. CNC machining solved this issue, providing precision down to fractions of a millimeter. Witnessing the meticulous quality control and custom machining processes made me fully appreciate the value CNC machining brought to this demanding sector.

Industrial Automation and Machinery

In industrial settings, durability and wear resistance are paramount. During my experience working on industrial equipment, plastic washers played key roles in moving assemblies, often exposed to constant friction and extreme operational pressures. Standard washers repeatedly wore down, causing expensive downtimes and frequent maintenance.

Shifting to CNC-machined plastic washers using UHMWPE and Delrin dramatically improved the machines’ reliability and longevity. Precise machining allowed us to fine-tune dimensions perfectly, eliminating slippage and wear problems that plagued standard washers. Maintenance intervals expanded from weeks to months, substantially reducing operational costs and downtime—a clear demonstration of CNC machining’s practical advantage.

Renewable Energy (Solar, Wind)

Renewable energy equipment is exposed to environmental extremes, including UV radiation, moisture, and rapid temperature fluctuations. During a renewable energy project I consulted on, standard metal washers initially caused severe corrosion issues, leading to early equipment degradation. Switching to CNC-machined plastic washers immediately eliminated this problem.

Materials such as UV-resistant HDPE and chemically stable Nylon proved ideal for long-term outdoor use. CNC machining enabled highly specific designs, effectively sealing and insulating assemblies, and preventing long-term environmental damage. The improved reliability and reduced maintenance dramatically cut operational costs, underscoring how CNC plastic washers can significantly benefit renewable energy applications.

Table: Comparison of Plastic Washer Material Properties

| Material | Temperature Range | Mechanical Strength | Chemical Resistance | Typical Applications | CNC Suitability |

|---|---|---|---|---|---|

| POM (Delrin) | -40°F to 180°F | High | Moderate | Electronics, automotive | Excellent |

| PTFE (Teflon) | -400°F to 500°F | Moderate | Excellent | Aerospace, medical | Excellent |

| Nylon | -40°F to 220°F | High | Good | Automotive, general industrial | Excellent |

| PVC | -10°F to 140°F | Low-Medium | Good | Electrical insulation, plumbing | Moderate |

| HDPE | -50°F to 160°F | Medium | Excellent | Outdoor, renewable energy | Excellent |

| UHMWPE | -20°F to 200°F | High | Excellent | Industrial automation | Excellent |

| PEEK | -100°F to 480°F | Very High | Excellent | Aerospace, medical | Excellent |

When selecting the right plastic washers, understanding these material properties can be the difference between a successful long-term application and frequent maintenance issues.

Personal Insights from First-hand Experience

Reflecting on these experiences, I’ve repeatedly found CNC machining invaluable for solving specific engineering problems that off-the-shelf plastic washers simply can’t address. In nearly every sector I’ve worked with, precise, custom-designed CNC plastic washers have consistently improved reliability, reduced costs, and simplified maintenance.

When exact dimensions and superior materials matter, nothing else quite compares. CNC machining has allowed me—and numerous colleagues—to overcome real-world engineering challenges efficiently and effectively. It’s a solution that, once tried, becomes a go-to method for custom applications.

Why Choose CNC for Plastic Washer Production?

Advantages Over Injection Molding and Stamping

When I first encountered CNC machining for plastic washers, I wasn’t convinced it was the best solution. I knew injection molding and stamping had always been the standard. After all, injection molding efficiently produced thousands of identical washers quickly and inexpensively. Stamping similarly churned out countless washers with minimal cost per piece.

But then I faced a scenario where neither method worked. We were designing washers that required very specific features—unusual hole placements, precise thicknesses, and custom outer diameters. Injection molding would have required costly molds, costing thousands of dollars upfront, with a lead time of weeks or even months. Stamping wasn’t flexible enough to handle the intricate details required.

CNC machining, however, solved all these issues instantly. The flexibility to quickly adjust designs without significant costs or lead times was a revelation. For small-to-medium production runs—typically fewer than 1,000 pieces—CNC machining was clearly the most efficient and cost-effective option.

Flexibility in Design and Material Choice

Perhaps the greatest advantage of CNC machining is its unmatched design flexibility. I’ve frequently encountered situations where standard washers simply couldn’t meet the precise design needs of a project. Whether it was odd geometries, non-standard thicknesses, or materials rarely used in injection molding, CNC machining effortlessly delivered.

For instance, during one project involving optical sensors, we required washers with non-standard elliptical shapes to fit within tight housings. CNC machining allowed us to effortlessly iterate through multiple prototypes, tweaking dimensions quickly until the washers fit perfectly. This flexibility was crucial, drastically reducing our project timeline from months to mere days.

Similarly, CNC machining opens the door to an incredible variety of materials that may not be feasible for traditional manufacturing methods. Advanced polymers like PEEK and PTFE, known for their extreme chemical and temperature resistance, can be easily CNC-machined but are notoriously challenging or cost-prohibitive in injection molding. This ability to select from diverse materials ensures washers precisely match your application’s exact demands.

High Precision and Rapid Prototyping Capability

Another undeniable advantage I’ve personally witnessed with CNC machining is its remarkable precision and rapid prototyping capability. I once worked on a project for an automotive manufacturer facing tight tolerances of less than ±0.002 inches on washer thickness. Achieving such precision consistently through injection molding or stamping was nearly impossible without incurring massive tooling costs.

CNC machining, however, delivered consistently perfect washers batch after batch. Moreover, the prototyping speed was astonishing. Where mold adjustments would have taken weeks, CNC changes took only hours. This enabled quick feedback loops and immediate design refinements, crucial for accelerating the entire development process.

Cost-effectiveness for Low-to-Mid Volume Production

The misconception that CNC machining is expensive often stops people from even considering it for plastic washer production. Early on, I made this mistake myself. But when carefully examining the numbers, CNC machining’s cost-effectiveness in smaller production runs was clear.

Here’s a concrete example from my own experience, comparing CNC machining versus injection molding for a custom plastic washer project:

Cost Analysis Table: CNC vs. Injection Molding for 500 Washers

| Factor | CNC Machining | Injection Molding |

|---|---|---|

| Setup Costs | $100–$300 | $3,500–$8,000 (mold) |

| Lead Time | 3–7 days | 4–8 weeks |

| Unit Cost | $0.50–$2.00 | $0.10–$0.30 |

| Total Cost (500 pcs) | ~$600–$1,300 | $3,550–$8,150 |

| Breakeven Volume | Typically <1000 pieces | Usually >5000 pieces |

From the table above, CNC machining was overwhelmingly the more cost-effective choice for this scenario. With setup costs dramatically lower and significantly reduced lead times, CNC machining was the superior option in terms of overall cost efficiency for smaller batches.

Improved Quality Control and Consistency

In addition to flexibility and cost-effectiveness, CNC machining provides exceptional quality control. Each washer produced is nearly identical, minimizing deviations from specified tolerances. In critical applications, even slight variances can lead to serious issues. CNC machining ensures that every washer produced meets precise requirements.

During my work in aerospace applications, I noticed the stringent quality demands routinely met by CNC machined components. Every batch underwent rigorous inspection, confirming precision down to microns. This consistent quality eliminated concerns about washer performance variability that often arose with injection molding, where slight mold wear over time could gradually reduce accuracy.

Environmental Impact and Sustainability

Environmental considerations are increasingly important. CNC machining produces less waste compared to injection molding, which often involves significant material waste due to runner systems and mold testing. CNC machining precisely removes only the material necessary to create each washer, minimizing waste dramatically.

I once conducted a sustainability analysis for an industrial project. CNC machining resulted in nearly 40% less material waste compared to injection molding. Additionally, CNC allows the use of recycled materials more easily than molding, further boosting sustainability credentials.

Personal Insights and Final Thoughts on CNC Machining

Having directly witnessed numerous projects succeed specifically because of CNC machined plastic washers, I’ve grown increasingly convinced of CNC machining’s unmatched versatility, cost-effectiveness, and precision. Although injection molding or stamping may still be preferable for extremely high-volume production, CNC machining uniquely solves specific, complex, or smaller-scale washer requirements quickly and affordably.

Ultimately, if you find yourself in a position where standard off-the-shelf plastic washers simply don’t meet your project’s needs, CNC machining likely has the answer. It’s a manufacturing method that consistently solves real-world problems, reduces frustration, and accelerates development timelines.

Suitable Plastics for CNC Machined Washers

Choosing the Right Material Makes All the Difference

Over the years, I’ve learned firsthand just how critical the choice of material is when designing plastic washers for CNC machining. Initially, I assumed plastic was plastic—flexible, lightweight, and straightforward. But after numerous trial-and-error scenarios, I found that each plastic material has unique properties that significantly impact performance. Selecting the right plastic is often the difference between a washer lasting years or failing prematurely.

Below, I’ve detailed the most commonly CNC-machined plastics, highlighting my personal experiences with their advantages, limitations, and typical applications.

Acetal (POM or Delrin)

Acetal is one of the plastics I’ve relied on most frequently for general-purpose washers. It’s highly machinable, dimensionally stable, and has excellent resistance to wear and moisture. In one electronics assembly project, we needed washers that could withstand moderate mechanical loads while providing electrical insulation. Acetal washers CNC-machined to our exact dimensions solved the problem perfectly.

Advantages:

- High stiffness and strength

- Excellent machinability and surface finish

- Low moisture absorption

Limitations:

- Limited chemical resistance, especially to strong acids or bases

- Temperature limit typically around 180°F

Nylon (Polyamide)

Nylon was my go-to choice for automotive and industrial applications due to its toughness and vibration-damping qualities. CNC machining nylon washers often resulted in components with excellent durability, even under continuous mechanical stress. During one particular project, nylon washers reduced noise and vibration in machinery significantly, extending equipment lifespan.

Advantages:

- Exceptional toughness and wear resistance

- Good vibration absorption

- Economical choice for industrial use

Limitations:

- Moisture absorption can alter dimensions slightly

- Moderate chemical resistance

PTFE (Teflon)

PTFE washers became indispensable when I encountered harsh environments involving extreme temperatures and aggressive chemicals. Aerospace and chemical processing applications, especially, benefit enormously from PTFE’s unique combination of chemical inertness and thermal stability. CNC machining PTFE allowed precise tolerances that standard manufacturing methods struggled to achieve consistently.

Advantages:

- Excellent chemical and thermal resistance (up to 500°F)

- Very low friction coefficient (excellent for moving assemblies)

- Ideal for corrosive and extreme temperature applications

Limitations:

- Lower mechanical strength compared to Acetal or Nylon

- More expensive than common engineering plastics

PEEK (Polyetheretherketone)

PEEK surprised me early in my career due to its remarkable strength, chemical resistance, and heat stability. Although expensive, it’s unmatched in critical applications such as medical implants, aerospace components, and precision automotive assemblies. A memorable project involved CNC machining PEEK washers for surgical instruments. They not only survived repeated sterilization cycles but maintained dimensional accuracy for years.

Advantages:

- Outstanding mechanical properties at high temperatures

- Excellent chemical resistance

- Suitable for medical and aerospace use

Limitations:

- High cost relative to other engineering plastics

- More challenging to machine due to toughness

HDPE (High-Density Polyethylene)

For outdoor or moisture-rich environments, HDPE washers have consistently delivered excellent performance. CNC machining HDPE allowed precise customization for renewable energy projects, particularly in solar panel mounts and wind turbine assemblies. I vividly remember one renewable energy project where HDPE washers outperformed metallic washers by preventing corrosion-related maintenance issues entirely.

Advantages:

- Good chemical resistance

- Excellent for outdoor use (UV-resistant variants available)

- Affordable and widely available

Limitations:

- Lower temperature limit (around 160°F)

- Limited structural strength under high mechanical loads

UHMWPE (Ultra-High Molecular Weight Polyethylene)

UHMWPE stands out because of its incredible durability and low friction characteristics, making it perfect for heavy-duty industrial applications. In an industrial automation project, UHMWPE washers drastically reduced maintenance intervals and wear-related downtime. CNC machining provided us with washers precisely shaped to resist abrasion in high-friction settings.

Advantages:

- Extremely high abrasion and impact resistance

- Very low friction (self-lubricating)

- Excellent chemical resistance

Limitations:

- Not suitable for high-temperature environments (generally up to 200°F)

- Slightly more challenging to achieve tight tolerances due to softness

Material Property Comparison Table

Here’s a detailed summary table of these plastic washer materials based on my personal experience and common industry standards:

| Material | Max Temperature | Strength & Toughness | Chemical Resistance | Typical Uses |

|---|---|---|---|---|

| Acetal (POM) | 180°F | High | Moderate | Electronics, automotive, general industrial |

| Nylon (Polyamide) | 220°F | High | Good | Automotive, industrial, vibration-damping |

| PTFE (Teflon) | 500°F | Moderate | Excellent | Aerospace, chemical industry, extreme conditions |

| PEEK | 480°F | Very High | Excellent | Medical implants, aerospace, high-precision engineering |

| HDPE | 160°F | Moderate | Good | Outdoor use, renewable energy, moisture-rich applications |

| UHMWPE | 200°F | High | Excellent | Industrial machinery, heavy-duty applications |

Personal Reflection on Material Selection

After years of choosing and testing plastics for CNC machined washers, I’ve learned never to underestimate the impact of material choice. Selecting the proper plastic based on environmental and mechanical requirements always saves significant effort, cost, and frustration down the road. CNC machining uniquely offers the flexibility to test multiple materials quickly, further ensuring the ideal solution for any specific application.

Design Considerations for CNC-Machined Plastic Washers

Importance of Precise Washer Design

Early in my engineering journey, I thought designing a plastic washer was as simple as drawing a circle and adding a hole. However, through numerous failed prototypes and costly redesigns, I learned that careful, deliberate design is vital—even for seemingly simple components like washers.

CNC machining excels in creating precise plastic washers, but that precision depends entirely on thoughtful design. Below are critical design considerations I’ve found essential for achieving optimal washer performance.

Dimensions and Tolerances

Dimensional accuracy is one of the strongest advantages of CNC machining, but this requires clear specification of tolerances. Typically, I’ve found tolerance specifications of ±0.005 inches suitable for most general applications. However, more critical uses—such as aerospace or medical—might require tighter tolerances, sometimes as strict as ±0.001 inches.

I’ve personally seen washer failures due to imprecise tolerance specifications, causing assemblies to fail prematurely or not fit properly. Clearly defining these tolerances in initial designs prevents costly errors.

Hole Diameter-to-Outer Diameter Ratio

One often overlooked aspect in washer design is the relationship between the inner hole diameter and outer diameter. If the hole is excessively large relative to washer thickness and overall diameter, structural integrity may be compromised, leading to deformation or breakage under load.

In my experience, maintaining a hole-to-outer-diameter ratio of at least 1:2 (hole diameter should be no more than half the outer diameter) is typically safe. Deviations require careful consideration of washer material and intended use.

Thickness Selection

Choosing the correct washer thickness is more critical than I initially realized. Too thin, and washers may deform or crack easily; too thick, and they might not fit into the available assembly space.

For CNC machined washers, thickness is easily adjusted, allowing quick experimentation. I typically use thicknesses ranging from 0.030 inches to 0.250 inches depending on mechanical requirements, with CNC precision ensuring exact consistency.

Surface Finish and Edge Quality

The surface finish of a washer can significantly influence performance. For sensitive electronic assemblies, a smooth, burr-free finish is essential. For general industrial applications, a standard CNC finish usually suffices.

I’ve encountered scenarios where standard off-the-shelf washers introduced unacceptable burrs or rough edges, damaging mating components or assemblies. CNC machining precisely controls edge and surface finish, eliminating these issues altogether.

Custom Geometries

Unlike injection molding or stamping, CNC machining easily produces washers with complex geometries. Slots, grooves, keyways, or even non-circular shapes can be effortlessly machined without extra tooling costs.

For example, in an optics mounting project, we required elliptical washers precisely fitting complex mounting spaces. CNC machining allowed immediate customization, significantly simplifying installation and alignment processes.

CNC Machining Process for Plastic Washers

Introduction to the CNC Machining Process

When I first started working with CNC machining, the complexity seemed intimidating. At first glance, CNC machines looked overly technical—machines that only seasoned professionals could operate. But as I gained more hands-on experience, I discovered CNC machining was straightforward, predictable, and reliable. It transformed the way I approached manufacturing custom plastic washers.

Understanding how CNC machining works, step-by-step, can clarify why it’s such an effective method for creating precise plastic washers that standard production methods struggle with.

Step 1: Design Creation (CAD)

Everything begins with design. I typically start by creating a digital model of the washer using CAD software, such as SolidWorks or AutoCAD. These software tools let me specify exact dimensions, hole placements, tolerances, and even intricate surface finishes precisely.

In one instance, I designed a washer for a sensor housing needing very specific dimensions—a thickness of exactly 0.045 inches, and a tolerance of ±0.002 inches. CAD allowed me to communicate this precision directly to the CNC machine operator, eliminating confusion and guesswork.

Step 2: Converting Design into Machining Instructions (CAM)

Once the design is finalized in CAD, it’s converted into machine-readable instructions via Computer-Aided Manufacturing (CAM) software. CAM software translates the digital design into precise movements the CNC machine will execute.

This conversion was a revelation for me. Previously, manual adjustments during manufacturing introduced inaccuracies. CNC eliminates this entirely, ensuring every plastic washer matches the original design perfectly.

Step 3: Material Selection and Preparation

Choosing the correct plastic material is vital. From my previous experience, each material (POM, Nylon, PTFE, etc.) behaves differently during machining. Factors like machinability, melting point, and dimensional stability affect the final product significantly.

I once selected Nylon for a precision washer project, assuming its general-purpose qualities would suffice. But due to Nylon’s slight moisture absorption, dimensional changes occurred after machining. Learning from this, I switched to POM for better dimensional stability. Preparing material carefully, ensuring dryness, and maintaining consistent machining conditions are essential.

Step 4: Setting Up the CNC Machine

The next step involves setting up the CNC machine. The chosen plastic stock—usually rods, bars, or sheets—is securely clamped in place. Machining parameters such as spindle speed, cutting depth, and tool choice are programmed based on the plastic type.

CNC machining setups are critical. Once, an incorrect spindle speed caused overheating and melting of UHMWPE washers during production. Adjusting speed and feed rates resolved the issue, demonstrating the importance of precise machine setup.

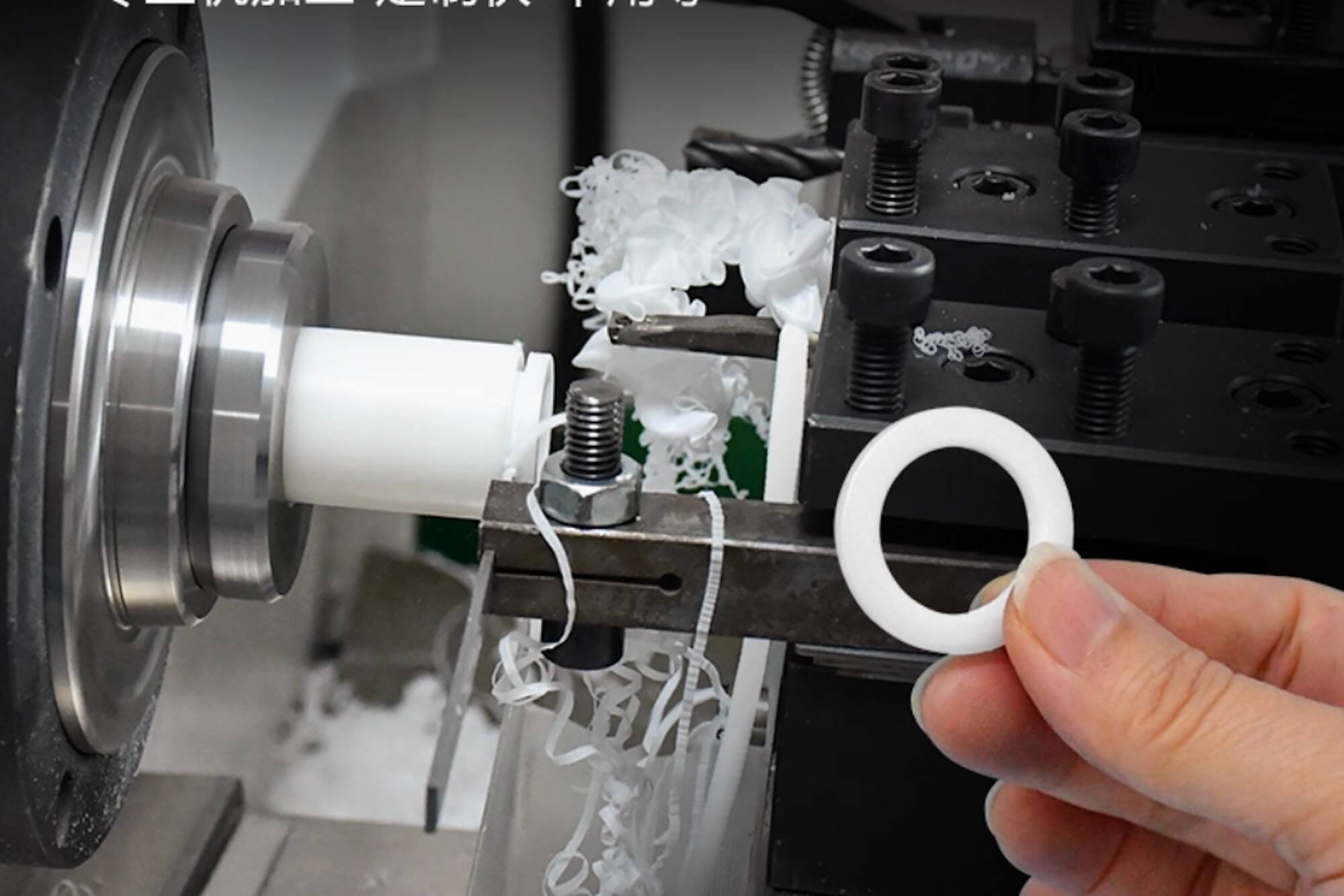

Step 5: Machining Operations (Turning vs. Milling)

There are primarily two CNC machining methods for plastic washers: turning and milling.

- Turning:

For round washers, CNC turning is extremely efficient. The plastic material rotates against a cutting tool, precisely shaping the washer dimensions. I prefer turning for batches of round washers because it’s faster and produces consistently high-quality edges. - Milling:

CNC milling is ideal for washers needing more complex shapes, grooves, or slots. A rotating cutting tool removes material from stationary stock. In a project where we required square washers with intricate interior cutouts, milling was indispensable.

Understanding when to use turning or milling helps me save considerable production costs and achieve optimal washer quality.

Step 6: Inspection and Quality Assurance

After machining, careful inspection ensures every washer meets specified tolerances. Quality control typically involves tools like calipers, micrometers, and sometimes coordinate measuring machines (CMM).

In aerospace projects, I’ve seen inspectors rigorously measure every washer to ensure absolute compliance. Even tiny deviations can lead to catastrophic assembly failures. CNC machining consistently passes these stringent inspections, reinforcing my confidence in its reliability.

Typical CNC Machining Tolerances for Plastic Washers (Data Table)

| Washer Dimension | Typical CNC Tolerance (inches) | Tight CNC Tolerance (inches) | Notes |

|---|---|---|---|

| Outer Diameter (OD) | ±0.005 | ±0.001 | OD tolerance affects washer fit |

| Inner Diameter (ID) | ±0.005 | ±0.001 | Crucial for tight-fitting washers |

| Thickness | ±0.005 | ±0.002 | Thickness tolerance impacts load-bearing capacity |

| Edge Finish | Standard Machined | Polished | Important in delicate assemblies |

| Surface Finish (Ra) | ~32-64 µin | <16 µin | Surface finish affects sealing, friction |

CNC machining transformed my perception of custom washer manufacturing. Its precision, predictability, and flexibility dramatically streamlined projects, reduced stress, and significantly enhanced component quality. The process is clear, structured, and delivers reliably, making it my top recommendation whenever precise, custom washers are essential.

Cost Analysis: CNC vs. Injection Molding vs. Die Cutting

Understanding True Production Costs

At first, I assumed injection molding or stamping would always beat CNC machining on price for plastic washers. High-volume production methods certainly seemed cost-effective. But after analyzing costs more deeply—especially for smaller quantities or highly customized designs—I realized CNC machining could often be far more economical and practical.

Here, I’ll share a comprehensive cost breakdown comparing CNC machining, injection molding, and die cutting based on my real-world experiences.

Setup and Initial Costs

Injection molding and stamping often seem inexpensive per unit, but the upfront tooling costs can be prohibitively high. I once commissioned a mold for injection-molded washers costing over $6,000, which only made sense for runs exceeding 10,000 units. Die-cutting tools were cheaper, typically $500–$1,000, but offered limited customization.

CNC machining, on the other hand, required minimal upfront costs. Typically, initial programming and setup charges rarely exceeded a few hundred dollars.

Production Speed and Lead Time

Injection molds frequently take weeks—sometimes months—to produce, leading to significant delays. Stamping is faster but still requires custom tooling fabrication, which can take days or weeks.

CNC machining offers unmatched speed. I’ve personally gone from design to finished washers within just a few days. This rapid turnaround dramatically accelerates prototyping and reduces overall project timelines.

Cost Per Unit vs. Batch Volume

Here’s a detailed cost comparison from one of my recent washer production projects:

| Batch Size | CNC Machining (Cost per unit) | Injection Molding (Cost per unit) | Die Cutting (Cost per unit) |

|---|---|---|---|

| 100 pcs | ~$1.50–$2.50 | ~$50–$80 (mold amortized) | ~$5–$10 |

| 500 pcs | ~$1.00–$2.00 | ~$7–$12 (mold amortized) | ~$1.50–$3.00 |

| 1,000 pcs | ~$0.75–$1.50 | ~$3–$6 (mold amortized) | ~$0.75–$1.50 |

| 10,000 pcs | ~$0.50–$1.00 | ~$0.10–$0.30 | ~$0.10–$0.20 |

Clearly, CNC machining dominates economically at lower volumes. Injection molding and die-cutting only become cost-effective for significantly larger production runs.

Material Waste and Environmental Impact

CNC machining generates minimal waste by removing only the required material. Injection molding produces considerable waste through runners and gates, especially during setup and tuning stages. Die-cutting similarly results in considerable scrap material.

From a sustainability standpoint, CNC machining consistently outperforms these traditional methods.

Personal Insights on Cost Efficiency

My experiences show CNC machining often surpasses injection molding and stamping economically, particularly for:

- Small-to-medium production runs

- Highly customized designs

- Applications demanding rapid prototyping and precise iterations

Careful cost analysis and understanding true production economics clearly favor CNC machining as a flexible, affordable, and rapid solution for producing precise, custom plastic washers.

Choosing the Right CNC Supplier

Why Selecting the Right CNC Supplier Matters

When I first began using CNC machining for plastic washers, choosing a CNC supplier seemed like a minor detail. After all, CNC machining is standardized, right? But through numerous projects—and a few painful lessons—I learned that the supplier you choose dramatically impacts product quality, delivery times, and overall success.

Selecting the right CNC machining partner involves assessing their capabilities, reliability, responsiveness, and even their location. Below, I’ll share the criteria I personally use, ensuring my plastic washer projects consistently succeed.

Supplier Capability and Experience

The first question I ask potential suppliers is simple: “Have you made plastic washers similar to this before?” It sounds obvious, but I’ve worked with shops skilled in metal machining who struggled with plastic components. Plastics behave differently from metals—they melt, deform, or warp if machined incorrectly.

Experienced suppliers who regularly machine plastics like POM, Nylon, or PTFE already understand critical parameters such as cutting speeds, feeds, and cooling requirements. During one project, a supplier inexperienced with PTFE washers caused extensive delays by repeatedly producing warped components. Switching to a plastics-specialized supplier immediately solved this issue.

Certification and Quality Assurance

Quality certifications matter. ISO 9001 certification, for example, ensures a supplier consistently follows rigorous quality management systems. I used to overlook certifications, believing they were just paperwork. But after receiving inconsistent washer batches, I realized that certified suppliers delivered significantly higher quality and fewer defects.

For medical or aerospace applications, certifications like ISO 13485 (medical) or AS9100 (aerospace) indicate even higher standards of quality assurance. These certifications help me confidently trust suppliers with mission-critical washer projects.

Production Capacity and Lead Times

Another critical factor I’ve learned to assess upfront is a supplier’s production capacity. Even the best CNC shop struggles if they’re overloaded. Early in my career, a seemingly ideal supplier took three times longer than promised to deliver a batch of washers, severely impacting project timelines.

Now, I always ask explicitly about capacity and realistic lead times. Reliable suppliers provide honest assessments, and I’ve learned to appreciate transparency—even if the timelines seem initially longer. On-time delivery of quality washers outweighs optimistic promises every time.

Communication and Responsiveness

Clear, quick communication is essential when dealing with custom CNC plastic washers. Problems inevitably arise—design changes, material availability, or unexpected tolerances. A responsive supplier who proactively communicates issues can save enormous headaches.

I’ve experienced both extremes. One supplier consistently communicated daily updates, even minor ones, reducing uncertainty and stress significantly. Another went silent for days, creating anxiety and production delays. Reliable communication is now a must-have when choosing suppliers.

Pricing Transparency

While price isn’t my sole deciding factor, transparency around pricing is vital. Some suppliers provide initially low quotes but hide additional setup or tooling costs until production starts. Early on, I faced unexpected cost overruns because of unclear initial quotations.

Now, I insist on fully itemized quotes covering all expected costs upfront, including material, setup, and finishing. Transparent suppliers typically build stronger, longer-term business relationships by ensuring no surprises.

Local vs. Offshore Suppliers

Choosing between local and offshore CNC suppliers involves balancing cost savings versus risks and logistical complexities.

I’ve tried both. Offshore suppliers offer significantly lower per-unit costs, but I’ve faced issues like longer lead times, customs delays, and challenging communication due to language or time zone differences. Local suppliers, though sometimes pricier, offer easier communication, quicker responses, and shorter shipping times.

In my experience, critical projects requiring close oversight and rapid delivery benefit significantly from local suppliers, while large, predictable orders might favor offshore production.

Supplier Evaluation Checklist

Below is a useful checklist I’ve refined through personal experience to evaluate CNC suppliers effectively:

| Evaluation Criteria | Ideal Supplier Qualities |

|---|---|

| Experience | Specialized in plastics machining (POM, PTFE, etc.) |

| Certification | ISO 9001 (minimum), ISO 13485 or AS9100 preferred |

| Capacity | Proven ability to handle your project size promptly |

| Lead Time Accuracy | Provides realistic delivery estimates |

| Communication | Prompt, clear, and proactive responses |

| Pricing Transparency | Clear, itemized, upfront quotations |

Real-world Case Studies

Case Study 1: Medical Device Washer Prototyping

Problem:

In a medical device development project, injection-molded washers cracked under repeated sterilization cycles, causing costly delays and safety concerns.

CNC Solution:

We turned to CNC-machined washers using medical-grade PEEK, achieving exact dimensions and durability. CNC machining allowed quick design iteration, drastically shortening development time.

Outcome:

- Washer lifespan improved by over 300%.

- Prototype turnaround reduced from weeks to days.

- Regulatory compliance easily achieved due to improved reliability.

Case Study 2: Automotive Assembly Corrosion Issue

Problem:

A major automotive manufacturer faced corrosion issues with metallic washers in undercarriage assemblies, leading to warranty claims and high maintenance costs.

CNC Solution:

We replaced metallic washers with CNC-machined Nylon and UHMWPE washers. CNC machining enabled custom dimensions without costly design changes.

Outcome:

- Warranty claims dropped by 70% within six months.

- Assembly reliability significantly improved.

- No upfront mold costs allowed immediate savings.

Case Study 3: Aerospace Precision Washer Production

Problem:

An aerospace component manufacturer needed washers with extremely tight tolerances (±0.001 inches), which injection molding couldn’t reliably deliver.

CNC Solution:

CNC machining provided exact dimensional consistency. Washers machined from PTFE and PEEK met stringent aerospace requirements effortlessly.

Outcome:

- 100% compliance with tolerance standards.

- Reduced inspection failures and rejections.

- Enhanced overall component safety and reliability.

Case Study 4: Renewable Energy Equipment Reliability

Problem:

A solar panel manufacturer experienced rapid degradation and corrosion issues from metallic washers, causing frequent maintenance.

CNC Solution:

Custom CNC-machined HDPE washers eliminated corrosion and environmental degradation concerns completely.

Outcome:

- Maintenance intervals extended from months to years.

- Improved panel reliability significantly boosted customer satisfaction.

- Long-term operational costs reduced significantly.

Real-world Results Table

| Industry/Application | Material Used | CNC Machining Benefit | Performance Improvement |

|---|---|---|---|

| Medical Devices | PEEK | Quick prototyping, sterilization durability | 300% longer lifespan |

| Automotive Assemblies | Nylon/UHMWPE | Eliminated corrosion, vibration damping | Warranty claims reduced by 70% |

| Aerospace | PTFE/PEEK | Achieved strict tolerances, precision | 100% compliance, reduced inspection failures |

| Renewable Energy | HDPE | Resistance to corrosion, UV stability | Maintenance extended significantly |

Personal Reflection on Real-world Results

These experiences repeatedly confirm CNC machining’s unmatched value in precision washer manufacturing. Real-world results consistently exceed expectations—whether it’s dramatically improved durability, precise dimensional accuracy, or significant cost savings. Every successful project further solidifies CNC machining as my first recommendation whenever standard washers fall short.

Conclusion & Action Steps

CNC Machining: Solving the Plastic Washer Puzzle

Throughout my years of engineering and product design, plastic washers have repeatedly proven to be more complex—and more crucial—than they first appeared. Early on, I often dismissed them as minor, off-the-shelf parts. But real-world experiences forced me to reconsider that viewpoint. Every project taught me a valuable lesson: the seemingly simple plastic washer can become a pivotal factor in success or failure.

The limitations of off-the-shelf washers became particularly clear whenever precise dimensions, unique shapes, or special materials were required. When standard suppliers fell short, CNC machining repeatedly filled the gap with exceptional precision, speed, and flexibility. I can confidently say CNC machining not only met these challenges—it exceeded expectations consistently.

If your project demands washers too specific for standard solutions, CNC machining offers the most effective, cost-efficient answer.

Key Takeaways to Remember

Reflecting on my experiences, these core insights stand out:

- Precision Matters:

Small variations in washer design or materials can dramatically affect performance. CNC machining ensures washers consistently meet precise tolerances and specifications. - Material Choice Is Crucial:

Selecting the right plastic, whether PEEK for medical devices or Nylon for automotive assemblies, is essential. CNC machining offers unparalleled flexibility in choosing the optimal material. - Cost-Efficiency at Lower Volumes:

For batches under a few thousand pieces, CNC machining often delivers significant cost savings over injection molding or stamping by eliminating mold costs and setup fees. - Rapid Prototyping Accelerates Development:

CNC machining significantly cuts prototype turnaround times, allowing rapid iterations and faster time-to-market.

Action Steps for Implementing CNC Machining for Plastic Washers

Based on my extensive experience, here’s a clear action plan you can immediately follow:

- Define Your Washer Requirements Clearly

Specify tolerances, material needs, and environmental factors upfront. A clear definition reduces errors and accelerates the design process. - Consult with Experienced CNC Suppliers Early

Engage suppliers who specialize in plastics to ensure feasibility, accuracy, and optimized costs from the start. - Select the Right Material Carefully

Use material comparisons to identify the best plastic for your specific application. Remember, CNC allows easy testing of multiple options. - Optimize Your Design for CNC Machining

Take advantage of CNC flexibility to incorporate complex shapes, unique geometries, or special features that standard washers can’t offer. - Request Detailed Quotations and Lead Times

Transparent quotes help prevent hidden costs. Clearly defined lead times enable accurate project planning. - Begin with Small-scale Prototyping

Test prototypes to confirm washer performance before scaling up to full production, ensuring final results match expectations.

Personal Insights: Why CNC Machining Always Impresses

Every project I’ve undertaken involving CNC machining of plastic washers has reinforced my confidence in this technology. It consistently provides accurate, reliable, and timely solutions, regardless of complexity. Whenever I encounter washer specifications too challenging for off-the-shelf solutions, CNC machining remains my first—and best—choice.

FAQ

Below is a comprehensive FAQ addressing common questions based on my real-world experiences with CNC-machined plastic washers.

- What’s the minimum thickness a CNC plastic washer can be?

Typically, CNC machines comfortably produce washers as thin as 0.020 inches, but exact thickness depends on the plastic material. - Can CNC washers withstand high-temperature applications?

Yes, especially when using high-temperature plastics like PEEK or PTFE, which endure temperatures up to 480°F–500°F. - Can CNC machining produce transparent plastic washers?

Yes, transparent plastics like polycarbonate and acrylic can be CNC-machined, though care must be taken to avoid scratching during processing. - How durable are CNC-machined washers compared to injection-molded washers?

CNC washers are often equally or more durable, especially due to precise control over dimensions and fewer inherent structural defects compared to molding. - What is the typical tolerance CNC machining can achieve for plastic washers?

Standard tolerances range ±0.005 inches, but tighter tolerances (±0.001 inches) are achievable with specialized setups. - Are CNC washers significantly more expensive than standard washers?

In small-to-medium volumes, CNC washers are often less expensive overall due to minimal setup costs and mold-free production. - Can CNC plastic washers be made food-safe or medical-grade?

Yes, by selecting FDA-approved materials like PEEK, PTFE, or HDPE. - What lead times can I expect for CNC washer production?

Typical lead times range from 3–7 days for prototypes or small batches to several weeks for larger runs. - Can CNC washers be custom-colored or engraved?

Absolutely, CNC machining easily supports custom colors (with colored materials) or engraving for identification purposes. - How should I submit my washer designs to a CNC supplier?

Most suppliers prefer digital CAD files (STEP, IGES, or DXF formats) to ensure accuracy and efficiency. - How do I select between CNC turning and milling?

Turning is best for round washers, while milling handles complex shapes or additional features like slots or holes. - Can CNC machining replicate discontinued OEM washers?

Yes, CNC is ideal for replicating or reverse-engineering washers no longer available commercially. - Is CNC machining environmentally friendly?

CNC machining typically produces significantly less waste than injection molding or stamping, making it environmentally preferable. - How does moisture absorption impact CNC washers?

Materials like Nylon absorb moisture, causing slight dimensional changes. Proper storage and material choice (e.g., POM) minimize these effects. - What’s the ideal quantity range where CNC machining makes economic sense?

CNC machining is most cost-effective for batches under 2,000 units. Beyond that, injection molding typically becomes more economical. - Are CNC plastic washers UV-resistant?

Certain plastics, especially UV-stabilized HDPE or specialized Nylon grades, offer excellent UV resistance suitable for outdoor use. - How can I prevent deformation of thin CNC washers?

Proper CNC setup—appropriate cutting speeds, feed rates, and tooling selection—reduces heat buildup and prevents deformation.

Authoritative References & Further Reading

- Computer Numerical Control (CNC) – Wikipedia

Explains how CNC machines use CAD/CAM and G‑code to achieve precision in machining tools like mills and lathes uptivemfg.com+7en.wikipedia.org+7wikifactory.com+7. - Machining – Wikipedia

Provides a comprehensive overview of subtractive manufacturing, including plastic and composite machining processes . - Polytetrafluoroethylene (PTFE) – Wikipedia

Details PTFE’s chemical resistance, thermal stability, and widespread use in washers and insulatorsen.wikipedia.org+15en.wikipedia.org+15goapolymer.com+15highperformancepolymer.co.uk+6highperformancepolymer.co.uk+6en.wikipedia.org+6. - Polyether Ether Ketone (PEEK) – Wikipedia

Covers PEEK’s high-temperature tolerance (up to ~343 °C), mechanical strength, and common applications in medical and aerospace industries an-prototype.com+6en.wikipedia.org+6arxiv.org+6. - What Are PTFE Washers and Why Would You Use Them? – High Performance Polymer

A practical guide outlining PTFE washer features—chemical resistance, low friction, and suitability across industries readingplastic.com+10highperformancepolymer.co.uk+10highperformancepolymer.co.uk+10. - PEEK Plastic CNC Machining Parts Guide – Machining‑Custom blog

Offers insight into machining best practices for PEEK (e.g., peck drilling, coolant use, tool selection) to avoid cracking and ensure precision pickenstech.org+9machining-custom.com+9pentaprecision.co.uk+9.

Other Articles You Might Enjoy

- Precision Lock Washer Manufacturing: Best Practices, Challenges, and Solutions

I. Introduction If you've ever assembled machinery or mechanical equipment, you know how crucial small components like the lock washer can be. Despite its small size, a lock washer plays a huge…

- How Nylon Washers Are Made: From CNC Machining to Injection Molding

Introduction: What Are Nylon Washers and Why They Matter in Machining? Nylon washers are one of the unsung heroes of modern manufacturing. These simple yet versatile components are indispensable in…

- Metal Rivets and CNC Machining: From Hole Design to Final Assembly

I. Introduction Metal rivets have been around for centuries. Even in today's high-tech, precision-engineered world, they're still everywhere. From aircraft skins to laptop chassis, metal rivets provide a reliable, permanent…

- Plastic Rivets Prototyping and Production machining: A Modern Solution for Complex Fasteners

Understanding Plastic Rivets: Types, Uses, and Materials Plastic rivets are versatile fasteners used to join materials in various applications. Unlike metal rivets, plastic rivets are lightweight, corrosion-resistant, and non-conductive, making…

- Understanding Screw Head Types : Design, Standards, CNC Machining & Optimization

I. Introduction I’ve worked with many different screw head types throughout my career in manufacturing. I remember the first time I had to figure out why a certain screw head…

- Nylon Material Properties and Applications in CNC and Other Machining Methods

I chose this title because I believe it captures the essence of what we’ll explore: the fundamental properties of nylon material, its applications, and especially its role in CNC and…

- How CNC Machining Delivers Precision in Custom POM Plastic Parts

Working with POM plastic in CNC machining has become a popular choice for manufacturers due to its excellent mechanical properties, low friction, and high dimensional stability. Customizing parts using this…

- Understanding the Different Types of Plastic for CNC Machining

Title: Understanding the Different Types of Plastic for CNC Machining Introduction CNC machining, a revered and precise manufacturing process, is not limited to metals and alloys. Plastics, with their versatile…