Introduction to 3D Printing and the Importance of Material Choice

The rapid proliferation of three-dimensional (3D) printing technology has imbued various industries with transformative prospects. In essence, 3D printing is a form of additive manufacturing that involves layer-by-layer creation of physical objects from digital models. Such a technique affords significant time, cost savings, and customizable diversity in item production.

However, the practical effectiveness and success of 3D printing are heavily contingent on the appropriate selection of materials used for printing. Different types of metals such as Titanium and Stainless Steel exhibit unique characteristics like tensile strength, corrosion resistance, weight, and thermal conductivity which make them suitable for specific applications. For instance, titanium’s high-strength, low-weight ratio, and bio-compatibility differentiate it as an ideal choice for medical or aerospace applications. Meanwhile, stainless steel’s affordability and durability render it apt for industrial components and consumer goods. Therefore, material-specific awareness equips designers and manufacturers to harness the immense potential offered by 3D printing judiciously, driving towards efficient product realization and scalability.

Understanding Titanium for Metal 3D Printing

Titanium is a highly valued material in the realm of metal 3D printing due to its unique combination of properties and advantages. This section explores the characteristics of titanium that make it an exceptional choice for 3D printing applications, especially in industries where strength, durability, and lightweight materials are crucial.

Key Properties of Titanium

Titanium is known for its outstanding strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. These properties make it an ideal material for aerospace, medical, and automotive applications. Additionally, titanium’s non-toxicity and biocompatibility are essential for medical implants and devices.

Advantages of Titanium in 3D Printing

- High Performance: The superior mechanical properties of titanium, including its high tensile strength and durability, contribute to the production of high-performance parts.

- Lightweight: Its low density makes it perfect for applications where reducing weight is critical, such as in aerospace and automotive industries.

- Corrosion Resistance: Titanium’s excellent resistance to corrosion extends the lifespan of parts exposed to harsh environments.

- Biocompatibility: The non-toxic nature of titanium makes it safe for medical applications, supporting the creation of implants and prosthetics.

Choosing the Right Titanium Grade for 3D Printing

Selecting the appropriate titanium grade is crucial for optimizing the properties of the final product. Factors to consider include the mechanical properties required, the environment in which the part will be used, and the specific 3D printing technology employed. Grades of titanium vary in terms of strength, machinability, and corrosion resistance, with pure grades being more suitable for corrosive environments and alloyed grades offering higher strength.

Applications of Titanium in 3D Printing

| Industry | Application |

|---|---|

| Aerospace | Functional components, engine parts, and lightweight structures. |

| Medical | Implants, prosthetics, and surgical instruments. |

| Automotive | High-performance parts and prototypes. |

In conclusion, titanium’s unique properties make it a highly sought-after material for metal 3D printing, offering advantages in strength, weight, and durability that are unmatched by many other metals. Its versatility across various industries underscores the importance of understanding titanium’s characteristics and applications in the context of 3D printing.

Understanding Stainless Steel for Metal 3D Printing

As one of the most widely used alloys, stainless steel proves to be a significant player in metal 3D printing. Its primary components are iron and carbon, mixed with elements like nickel and chromium to enhance its characteristics that make it attractive for 3D printing.

- Stainless steel is inherently strong, providing excellent structural support.

- Its corrosion resistance makes it ideal where durability against wear and tear is essential.

- Maintains properties even at high temperatures, perfect for applications that involve heat exposure.

However, using stainless steel in 3D printing isn’t without complications. The material’s hardness can potentially cause issues during the post-processing stage, as it could result in equipment damage or require more elaborate techniques to achieve desired results. There may also be concerns about consistency; the quality of parts printed depends on various factors such as printer settings, precision, and even the grade of stainless steel powder used. Despite these challenges, proper education and understanding of material behaviour can optimize its use and harness the beneficial features of stainless steel in 3D printing.

Comparison between Titanium and Stainless Steel in 3D Printing

In terms of durability and strength, titanium proves to be superior against stainless steel. Specifically, where stainless steel typically has a tensile strength around 505 megapascals (MPa), titanium offers an impressive 950 MPa, nearly doubling the capability. It also features higher ductility allowing more flexibility without deforming permanently. However, such qualities come at a cost as titanium is significantly pricier than stainless steel.

- Durability & Strength: The comparative analysis reflects vastly favorable results for titanium over stainless steel considering its exceptional tensile strength and ductility.

- Cost-effectiveness: Despite its evident qualities, affordability becomes a considerable factor in choosing materials. Here, stainless steel stands out due to its lower cost compared to titanium.

- Suitability: In view of distinct project requirements, both metals have unique applications. While titanium’s high strength-to-weight ratio suits aerospace or medical industries, stainless steel’s resistance to corrosion makes it ideal for chemical processing industries.

In any case, choosing between these two fundamentally depends on balancing budget constraints with specific demands of a project.

Case Studies: Utilizing Titanium and Stainless Steel in 3D Printing

In unique real-world scenarios, both titanium and stainless steel have found established value within the realm of 3D printing. Stressing on employment of titanium first, let’s examine an instance where its usage served major benefits. Aerospace industries frequently employ titanium for 3D-printed components largely because it offers high strength-to-weight ratio coupled with excellent resistance to corrosion. For example, GE Aviation has successfully manufactured fuel nozzles for jet engines using this technology, thereby resulting in lighter, yet more durable parts.

- Benefits: High Strength, Lightweight, Corrosion Resistant

- Results: More Durable Parts, Enhanced Performance

Switching to another metal option – stainless steel, there lies a consequential examination of its effects when used in 3D printing. Within the medical industry, stainless steel is commonly utilized owing to its cost-effectiveness combined with robust mechanical properties. A case-in-point is production of surgical instruments via 3D printing – done by companies like Biomodex. This approach led to creation of custom-made tools that were economically viable while being high-quality enough for precision tasks. The affordability allowed small healthcare facilities to participate in advanced medical procedures without immense expenditure.

- Effect: Cost-Effective, Customizable Tools

- Outcome: Affordable Medical Advancements, Wider Accessibility

Final Verdict: Choosing Between Titanium and Stainless Steel

After comparing the key factors related to 3D printing with titanium and stainless steel, it is clear that both metals hold significant advantages in their respective domains. Titanium excels in terms of strength-to-weight ratio, corrosion resistance, and biocompatibility which renders it suitable for high-performance industries like aerospace and medical applications. On the contrary, stainless steel stands out due to its ductility, temperature resistance, and cost-effectiveness, making it a viable choice for general engineering purposes and mass production.

- Titanium’s advantages include an impressive strength-to-weight ratio, outstanding corrosion resistance, and excellent biocompatibility.

- In contrast, stainless steel shines with its innate ductility, commendable temperature resistance, and notably cheaper costs.

In conclusion, the decision between titanium and stainless steel depends largely on the requirements of the specific application at hand; whether factors such as superior mechanical properties or cost-efficiency take precedence. Both materials have strong technical merits, so the final selection comes down to individual project needs.

Related Posts

- Metal 3D Printing Showdown: Titanium vs. Stainless Steel

Metal 3D Printing: An Introduction to Titanium and Stainless Steel 3D printing, otherwise known as additive manufacturing, refers to a process that creates three-dimensional objects from digital models. It's used…

- Types of Stainless Steel and Stainless Steel Grades

Stainless steel, renowned for its corrosion resistance, is a vital material in various industries, from construction to culinary tools. This article delves into the types of stainless steel and their…

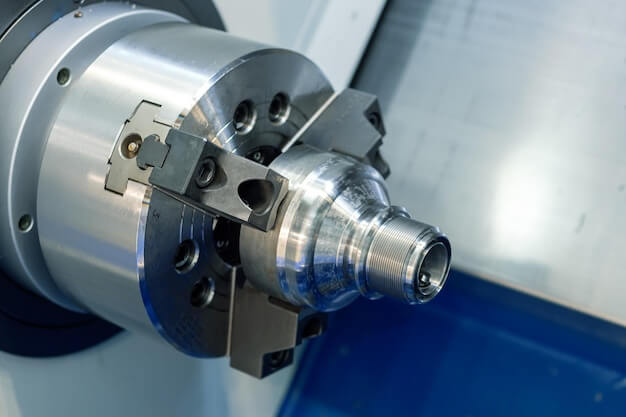

- CNC Machining in the Watchmaking Industry: Stainless Steel vs. Titanium Cases

CNC Machining and its Role in the Watchmaking Industry In the world of horology, CNC machining has proven itself to be an invaluable tool. This modern method allows custom parts…