Introduction: The Crucial Role of Sheet Metal Fabrication and the Fusion of Traditional Craftsmanship with Modern Technology

Sheet metal fabrication, an essential process in numerous industries such as construction, automotive, aerospace, and electronics, involves shaping, cutting, and assembling parts from a metal sheet. With its versatility and flexibility, it can produce diverse components varying in complexity, size, and design. This process uniquely marries traditional craftsmanship- —attentiveness to detail, knowledge about materials, proficiency in techniques— with the advancements of modern technology. In particular, Computer-Aided Design (CAD) and Computer Numerical Control (CNC) machines enhance accuracy, efficiency, repeatability, and offer greater scope for customization. While craftsmen rely on their skills honed over years of experience, these new technologies enable them to perform tasks that once posed difficult challenges like precise cuts or replicating intricate designs consistently.

Traditional Sheet Metal Fabrication Techniques

Sheet metal fabrication has a rich history that dates back thousands of years. The traditional methods employed, such as riveting and soldering, are hailed for their simplicity but remarkably enduring efficacy. Fundamental to these age-old techniques are the principles of measurement accuracy, material knowledge, and tool mastery – cornerstones that lie at the heart of this craft. A prime example of traditional sheet metal fabrication techniques is hand-forming processes like bending, cutting, and forming passed down through generations. These involve shaping metal with simple tools and raw human effort, an unaltered thread of tradition making each piece bear a mark of unique craftsmanship crafted over time. Traditional techniques continue to hold relevance even in modern production settings, often complementing emerging technology.

Challenges Faced by Traditional Methods in Sheet Metal Fabrication

In the domain of sheet metal fabrication, traditional methods present several hindrances, majorly related to precision and efficiency. Despite the expertise imbued through years of craftsmanship, manual processes can be time-consuming and often lack the exactitude necessary for intricate designs. For instance, manually cutting the metal sheets may result in inconsistencies in measurements due to human errors, potentially compromising the overall quality of the finished product. Such issues highlight the limitations of conventional techniques, accentuating the need for incorporating modern technology in order to streamline the fabrication process, enhance accuracy, and ultimately improve productivity.

Benefits and Application of Modern Technology in Sheet Metal Fabrication

The integration of modern technology into sheet metal fabrication has revolutionized the industry, offering unprecedented precision, efficiency, and versatility. This evolution has enabled the production of components with complex geometries and has significantly reduced waste, making the process more sustainable and cost-effective.

Key Benefits of Modern Technology in Sheet Metal Fabrication

- Enhanced Precision: Advanced cutting and forming techniques, such as laser cutting and CNC bending, ensure components are produced with high accuracy.

- Increased Efficiency: Automation and software integration streamline the fabrication process, reducing lead times and increasing throughput.

- Material Optimization: Sophisticated software tools enable optimal material utilization, minimizing waste and reducing costs.

- Design Flexibility: Modern technologies allow for the fabrication of parts with complex shapes and intricate details, expanding design possibilities.

Applications of Modern Technology in Sheet Metal Fabrication

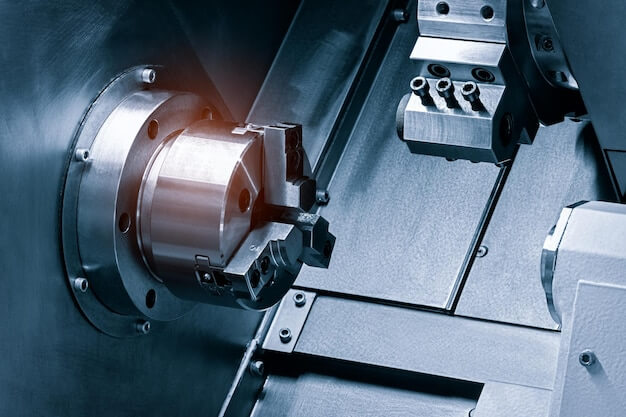

Modern technology finds application across various stages of the sheet metal fabrication process, from design to finishing. Cutting-edge techniques such as laser cutting, plasma cutting, and water jet cutting are employed for precise material cutting. Forming processes leverage CNC machinery for bending and stamping, ensuring consistent and accurate shapes. Additionally, advanced joining methods like welding and adhesive bonding are utilized for assembly, while finishing techniques such as powder coating and anodizing enhance the aesthetic and functional properties of the final products.

| Technology | Application | Benefit |

|---|---|---|

| Laser Cutting | Cutting | Precision in complex geometries |

| CNC Bending | Forming | Accuracy and repeatability in bends |

| Plasma Cutting | Cutting | Efficiency in thick material cutting |

| Water Jet Cutting | Cutting | Versatility in cutting various materials |

| Welding/Adhesive Bonding | Joining | Strength and durability in assembly |

| Powder Coating/Anodizing | Finishing | Enhanced surface properties |

By leveraging modern technology, sheet metal fabrication has become more efficient, precise, and versatile, enabling the production of high-quality components for a wide range of applications in industries such as aerospace, automotive, and construction.

Benefits of Combining Craftsmanship with Technology in Sheet Metal Fabrication

The fusion of traditional craftsmanship and advanced technology in sheet metal fabrication offers significant benefits, the most notable being improved accuracy and consistency in products. Technological advancements like Computer Numerical Control (CNC) machining enable precise measurements and cuts which minimize errors, resulting in a consistently high-quality output. This amalgamation also enhances productivity by automating complex processes that were traditionally time-consuming, thereby reducing lead times. For instance, intricate designs that would take craftspeople countless hours to complete manually can now be effortlessly achieved through modern techniques such as CNC machining. Additionally, this perfect blend allows manufacturers to quickly adapt to various design changes while maintaining superior product quality.

Collaboration between Craftspeople and Technicians: Striking a Balance

In the realm of sheet metal fabrication, the harmonious collaboration between seasoned craftspeople and savvy technicians plays an integral role. This synergy is triggered by an exchange of knowledge and teamwork – underpinning the mutual importance each brings to every project. While craftspeople hold essential information derived from years of traditional craftsmanship, technicians broaden this versatility through modern technology. Striking the right balance between these two expertise aids in maximizing productivity and optimization of results. A quintessential example would be a scenario where skilled artisans work alongside engineers in a fabrication workshop. Here, traditional metal shaping techniques flawlessly intersect with advanced technologies, allowing for intricate designs and efficient production without compromising on the quality or authenticity of the final product.

Future Trends and Innovations in Sheet Metal Fabrication

The field of sheet metal fabrication is currently experiencing a surge of innovation, fueled by emerging technologies such as 3D printing and robotics. These advancements are transforming traditional processes into highly efficient and precise operations, leading to improved product quality and increased production speed. Furthermore, there’s growing interest in the exploration of sustainable materials and eco-friendly processes. Recycling scrap metals for use in fabrication, for example, offers an environmentally-conscious alternative that reduces waste and conserves natural resources. This shift not only fosters sustainability but also adheres to increasingly strict environmental regulations. Therefore, blending traditional craftsmanship with cutting-edge technology and ecologically responsible practices delineates the promising future of sheet metal fabrication.

Other Articles You Might Enjoy

- Advanced Sheet Metal Fabrication Solutions for the Electronic Sector

Sheet metal fabrication stands as a crucial process within the electronics industry, instrumental in crafting a plethora of components that underpin electronic devices. This technique involves shaping and joining metal…

- Tips on Minimizing The Cost of Sheet Metal Fabrication

Sheet metal fabrication refers to a variety of manufacturing processes that are used to create sheet metal. We can use multiple processes, including bending, punching, and welding, to create intricate…

- Sheet Metal Fabrication for Automotive Industry

Introduction to Sheet Metal Fabrication in the Automotive Industry Sheet metal fabrication is a cornerstone process in the automotive industry, essential for constructing vehicle frames, bodies, and components. It involves…