The Future of Manufacturing: Exploring the Potential of Insert Molding in CNC Machining

As the manufacturing industry evolves, innovative techniques such as insert molding are reshaping the landscape of CNC machining. This article delves into the potential of insert molding in CNC machining processes, exploring its capabilities, applications, and the transformative impact it holds for the future of manufacturing. Aluminum CNC Machining Service for Custom Parts Understanding Insert […]

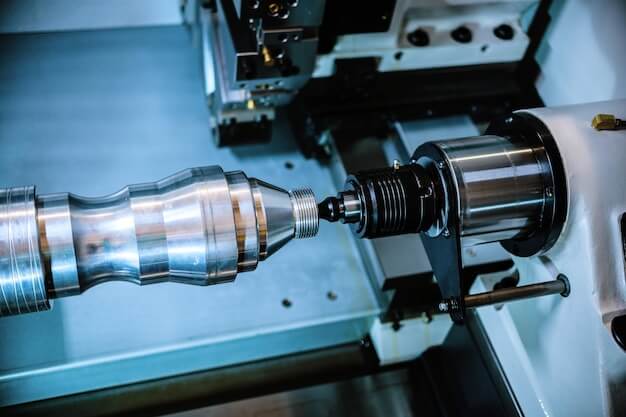

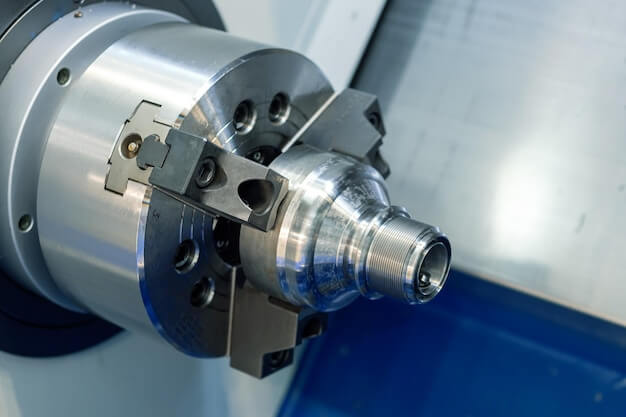

Optimizing Tool Paths: Advanced Techniques for Efficient CNC Titanium Machining in China

Introduction to CNC Titanium Machining in China In the dynamic landscape of global manufacturing, China stands out, especially in CNC (Computer Numerical Control) machining. Titanium, prized for its strength and corrosion resistance, is widely used in sectors like aerospace and medical devices. Yet, machining titanium is complex due to its tough nature. For example, a […]

Aluminum CNC Machining Service for Custom Parts

Aluminum CNC machining stands at the forefront of modern manufacturing, epitomizing precision, versatility, and efficiency. With its widespread applications across industries ranging from aerospace to automotive and beyond, aluminum CNC machining has revolutionized the production of intricate components with unparalleled accuracy and consistency. Why use CNC machining of aluminum alloy? At the heart of aluminum […]

In the field of CNC machining Which materials require heat treatment?

Introduction to CNC Machining and the Role of Heat Treatment CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, enabling the precision crafting of parts with minimal human intervention. Through programmed commands, CNC machines repetitively produce complex shapes that are essential in various industries, ranging from automotive to aerospace. Integral to this […]

Challenges posed by material ductility in CNC machining

Understanding Material Ductility in CNC Machining In the realm of Computer Numerical Control (CNC) machining, where precision and accuracy are paramount, material ductility represents a significant factor influencing the quality and efficiency of the manufacturing process. The intrinsic ability of metals to deform under tensile stress without fracturing is what defines their ductility. Grasping the […]

Analysis of processing difficulty of different materials in CNC processing

Introduction to CNC Processing and Material Selection CNC processing, a cornerstone of modern manufacturing, stands for Computer Numerical Control machining, a method where pre-programmed software commands the movement of factory tools and machinery. The selection of materials in CNC machining is critical; it not only influences the final product’s attributes but also affects the ease […]

Sheet Metal Fabrication for Automotive Industry

Introduction to Sheet Metal Fabrication in the Automotive Industry Sheet metal fabrication is a cornerstone process in the automotive industry, essential for constructing vehicle frames, bodies, and components. It involves cutting, bending, and assembling sheets of metal to create precise shapes and structures tailored for specific functions within a car. The significance of this technique […]

Here are 7 tips for reducing costs in CNC machining.

Introduction to Cost Reduction in CNC Machining CNC machining stands as a pivotal manufacturing process where computer-guided machinery produces complex parts with precision. In an industrial landscape where the push for cost-effectiveness parallels demands for high quality, strategies to trim down expenditures without compromising on output are essential. The upcoming tips highlight how manufacturers can […]

Is titanium magnetic? what is titanium ?

Introduction to Titanium Titanium is a strong, lightweight metal known for its excellent corrosion resistance, high strength-to-weight ratio, and ability to withstand extreme temperatures. These properties make it an essential material in industries such as aerospace, medical, and automotive manufacturing. One of the key advantages of titanium is its resistance to corrosion, which makes it […]

Titanium is used in the production of medical and aerospace instruments.

Unique Properties of Titanium Titanium, a lustrous transition metal with a low density and high strength, stands out for its remarkable resistance to corrosion and ability to withstand extreme temperatures. These unique properties make it an ideal material for demanding engineering applications, particularly in the medical and aerospace sectors. Its biological inertness allows for its […]

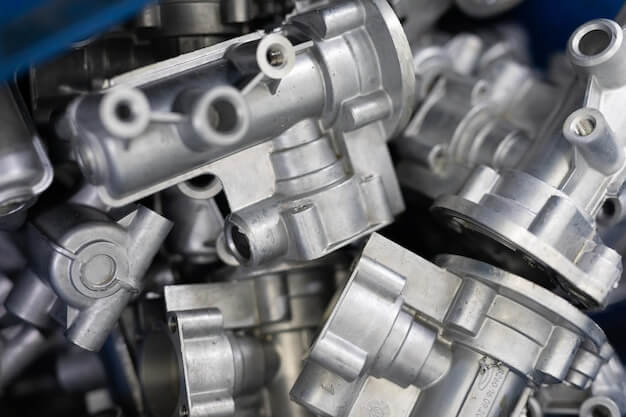

Exploring the World of Non-Ferrous Metals: Characteristics, Applications, and Innovations

Introduction to Non-Ferrous Metals Non-ferrous metals, distinguished by their lack of iron content, are highly valued for their versatility and distinct properties such as resistance to corrosion, high conductivity, and lightweight. These characteristics make them indispensable across a wide array of industries including aerospace, automotive, electronics, and construction. For example, aluminum’s combination of low density […]

Different types of casting

Introduction to Casting in Manufacturing Casting is a foundational manufacturing process wherein molten material—often metal—is poured into a pre-shaped mold and allowed to solidify, forming a replica of the mold’s internal geometry. This technique enables the production of complex shapes that would be challenging or uneconomical to achieve through other methods. The versatility of casting […]