Material Considerations in CNC Machining: Selecting the Right Substrate

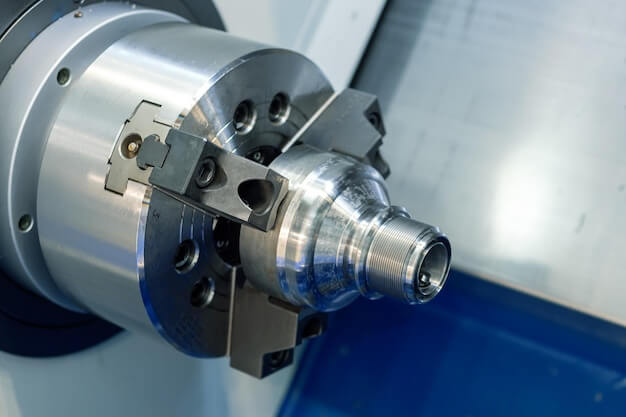

CNC Machining and its Dependence on Material Selection The use of Computer Numeric Control (CNC) machining is deeply rooted in today’s manufacturing industry due to its exceptional capacity for precision, automation, and the wide-collection of materials it can effectively manipulate. CNC machining machines a material block into specified dimensions by exercising programmed instructions without manual […]

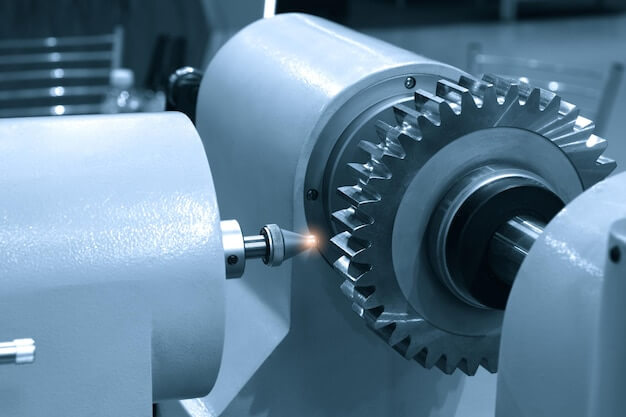

Maximizing Efficiency in CNC Machining: Material Specific Tooling and Techniques

Introduction to CNC Machining and its Efficiency Computer Numerical Control (CNC) machining is a manufacturing process that involves computer use for handling machine tools. The primary function of these machines is to perform varying tasks such as drilling, cutting or shaping materials like metal, plastic, wood, etc., through the direction of tool paths guided by […]

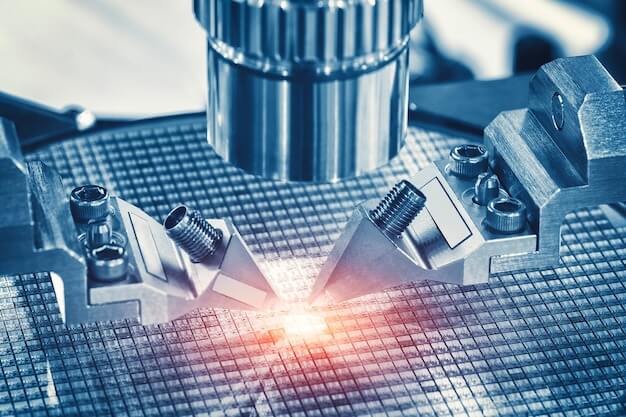

The Science Behind Material Removal Rates (MRR) in CNC Machining

Introduction: Understanding Material Removal Rates (MRR) in CNC Machining In the field of CNC machining, understanding the concept of Material Removal Rates (MRR) is critical. MRR defines the volume of material a cutting tool removes per unit time, usually measured in cubic inches per minute (in³/min). In other words, it denotes how swiftly a machine […]

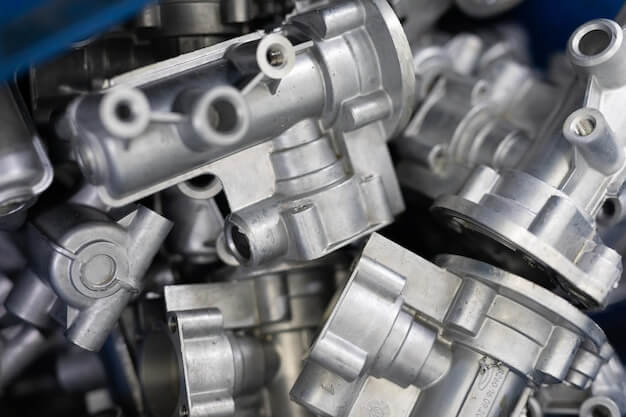

CNC Machining for the Automotive Industry: Steel vs. Aluminum Weight and Strength Analysis

CNC Machining and Its Use in the Automotive Industry: Steel vs. Aluminum CNC (Computer Numerical Control) machining, a method used to control machine tools via computers, has proven indispensable in several industries – one of them being the automotive industry. An integral part of vehicle manufacturing process, CNC machining offers significant benefits such as accuracy, […]

CNC Material Efficiency: Aluminum 2024 vs. 6061 vs. 7075

CNC Machining and Material Efficiency: Aluminum 2024 vs. 6061 vs. 7075 CNC machining refers to a highly automated process widely employed in the manufacturing sector, using computer numerical control (CNC) to dictate the movements of machinery tools. This method allows for greater control and precision in manufacturing many different kinds of materials, including aluminum. The […]

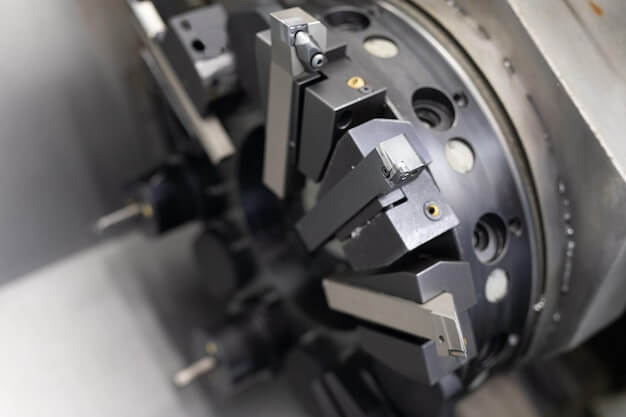

The Engineer’s Guide to Reducing CNC Machining Time: Material and Tool Selection Strategies

Importance of Reducing CNC Machining Time In the expansive world of industrial manufacturing, Computer Numerical Control (CNC) machining holds a dominant place due to its effectiveness in reducing errors, enhancing efficiency, and improving final product output. Despite these advantages, one key challenge that many engineers frequently encounter is the lengthy machining time attributed to this […]

Environmental Impact of CNC Machining: Recyclable Metals vs. Biodegradable Plastics

Introduction to CNC Machining and its Environmental Impact CNC (Computer Numerical Control) machining is a prevalent manufacturing process wherein pre-programmed computer software dictates the movement of factory tools and machinery. This allows for efficient, precise, and repeatable production of complex parts – metal or plastic. In today’s climate-conscious society, the environmental impact of processes like […]

Stainless Steel vs. Aluminum in CNC Machining: Pros and Cons

CNC Machining and the Importance of Material Selection CNC machining, a pivotal manufacturing process in numerous industries, uses pre-programmed computer software to dictate the movement of factory tools and machinery. Techniques such as milling, turning, drilling, and grinding are executed with precision even for complex shapes and intricate designs. Among key factors determining success in […]

Powder Metallurgy Materials: Stainless Steel vs. Cobalt Chrome

Introduction to Powder Metallurgy Materials Powder metallurgy materials play a vital role in various industrial sectors. Predominantly used for the manufacture of tools, these materials are compacted into solid parts using heat treatment processes. The key advantage of these powdered metals includes their ability to retain intrinsic properties, unlike traditional melting and casting methods. Stainless […]

The Engineer’s Choice: Titanium Grade 5 vs. Grade 23 for CNC Medical Implants

CNC Medical Implants: Material Choices and their Significance Computer Numerical Control (CNC) medical implants are an integral part of modern healthcare, designed with precision to replace missing or damaged body parts. With the unprecedented advancements in technology, customizing these implants for every patient’s unique needs has become possible, ensuring better health outcomes and faster recovery […]

The Ultimate Guide to Sheet Metal Materials: Aluminum vs. Galvanized Steel

Introduction: A Brief Overview of Sheet Metal Materials in Manufacturing In the wide world of manufacturing, sheet metal materials play a pivotal role. They serve as critical components in various industries including automotive, aerospace, and construction. The two primary types of these metals often used are Aluminum and Galvanized Steel due to their unique properties. […]

Metal 3D Printing Showdown: Titanium vs. Stainless Steel

Introduction to 3D Printing and the Importance of Material Choice The rapid proliferation of three-dimensional (3D) printing technology has imbued various industries with transformative prospects. In essence, 3D printing is a form of additive manufacturing that involves layer-by-layer creation of physical objects from digital models. Such a technique affords significant time, cost savings, and customizable […]