When it comes to CNC machining, making the right technical decisions is crucial. These decisions not only affect the quality of the final product but also the efficiency of the entire machining process. From choosing the optimal spindle speed and feed rate to determining the best tool paths and cutting depths, every choice plays a significant role. Let’s explore how to make these decisions effectively to achieve the best results.

Spindle Speed and Feed Rate

Selecting the correct spindle speed and feed rate is the foundation of CNC machining. These parameters must be chosen based on the material being machined, the type of cutting tool used, and the specific operation being performed.

Spindle Speed: The spindle speed, measured in revolutions per minute (RPM), determines how fast the cutting tool rotates. The right speed depends on the material hardness and the tool material. For example, harder materials like steel require slower speeds, while softer materials like aluminum can be machined at higher speeds.

Feed Rate: The feed rate, measured in millimeters per minute (mm/min) or inches per minute (IPM), dictates the speed at which the workpiece is fed into the cutting tool. A higher feed rate is suitable for roughing operations where large amounts of material are removed quickly. In contrast, finishing operations require lower feed rates to achieve a smoother surface finish.

Here’s a simple guide to choosing spindle speed and feed rate for different materials:

| Material | Tool Material | Spindle Speed (RPM) | Feed Rate (mm/min) |

|---|---|---|---|

| Aluminum | High-Speed Steel | 6000 | 500 |

| Steel | Carbide | 1500 | 200 |

| Brass | High-Speed Steel | 4000 | 300 |

| Cast Iron | Carbide | 1000 | 150 |

Cutting Depth and Width

The depth and width of each cut significantly impact the machining process. These parameters must be chosen carefully to balance efficiency with tool life and workpiece quality.

Cutting Depth: The cutting depth refers to how deep the cutting tool penetrates the material in a single pass. Deeper cuts remove more material but increase the load on the tool and machine. Shallow cuts are less taxing but require more passes to remove the same amount of material.

Cutting Width: The cutting width, or step-over, is the width of material removed in one pass of the tool. Similar to cutting depth, a wider cut can remove more material quickly but at the expense of higher tool wear and potential deflection.

Tool Paths

The tool path is the route taken by the cutting tool to machine the part. Efficient tool path planning is critical for minimizing machining time and ensuring high-quality finishes. There are two main types of tool paths in CNC machining: point-to-point (also known as positioning) and continuous (or contouring) paths.

Point-to-Point Tool Paths: These are used for operations like drilling, tapping, and boring, where the tool moves from one fixed point to another. The tool moves rapidly between points without cutting, which is ideal for operations that require precision at discrete locations.

Continuous Tool Paths: These are used for operations like milling and turning, where the tool moves continuously along a path to shape the material. Continuous paths are essential for contouring operations where smooth transitions and accurate profiles are required.

Machine Power and Cutting Forces

Understanding the power capabilities of the CNC machine and the cutting forces involved is vital. Each machine has a specified power rating, typically given in kilowatts (kW) or horsepower (HP). Exceeding this power can cause damage to the machine and tool, so it’s crucial to stay within the machine’s capabilities.

Here’s a useful conversion for machine power:

- 1 kW ≈ 1.34 HP

- 1 HP ≈ 0.75 kW

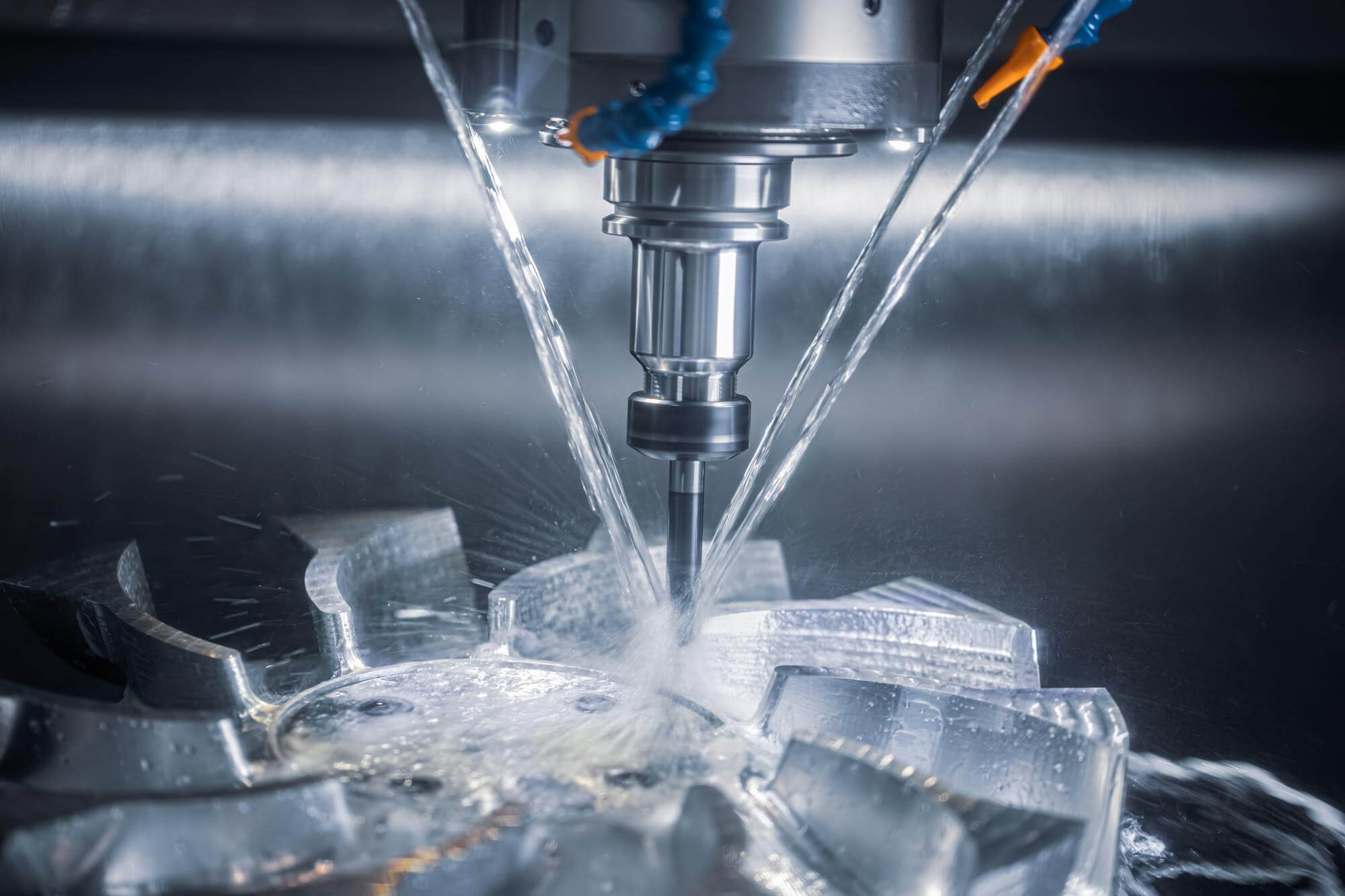

Coolants and Lubricants

Using the right coolants and lubricants is essential for managing the heat generated during machining and extending tool life. Coolants help dissipate heat from the cutting area, while lubricants reduce friction between the tool and the workpiece.

Types of Coolants:

- Water-Soluble Oils: These are the most common and provide good cooling and lubrication.

- Synthetic Fluids: These offer excellent cooling but less lubrication.

- Straight Oils: These provide the best lubrication but less cooling.

Example: Machining a Steel Part

Consider machining a steel part with the following requirements:

- Initial Setup:

- Material: Steel

- Tool: Carbide end mill

- Spindle Speed: 1500 RPM

- Feed Rate: 200 mm/min

- Roughing Operations:

- Cutting Depth: 2 mm

- Cutting Width: 10 mm

- Coolant: Water-soluble oil

- Finishing Operations:

- Cutting Depth: 0.5 mm

- Cutting Width: 2 mm

- Coolant: Synthetic fluid for better cooling

By carefully selecting these parameters, the machining process will be efficient, and the final part will meet the desired specifications.

Optimizing spindle speed, feed rate, tool paths, and the use of coolants are critical decisions in CNC machining. By understanding and applying these principles, machinists can achieve high-quality results efficiently. Whether you’re machining simple parts or complex components, the right technical decisions make all the difference in CNC machining.

Other Articles You Might Enjoy

- The Impact of Material Selection on CNC Machining Speed and Tool Wear

Introduction to CNC Machining CNC machining stands as a cornerstone in modern manufacturing, offering precision and efficiency in producing parts. At its core, CNC (Computer Numerical Control) machining involves the…

- Program Data Multipliers in CNC Machining Parts: Optimizing Speed and Feed Rates

In the realm of CNC machining, fine-tuning the machine's performance can lead to significant improvements in both efficiency and quality. One crucial aspect of this tuning process involves the use…

- Tool compensation in CNC machining, our quest for precision in CNC machining

Introduction to CNC Machining and Precision CNC (Computer Numerical Control) machining stands at the forefront of modern manufacturing, utilizing computerized controls to operate complex machinery with remarkable accuracy. This process…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Optimizing Tool Paths: Advanced Techniques for Efficient CNC Titanium Machining in China

Introduction to CNC Titanium Machining in China In the dynamic landscape of global manufacturing, China stands out, especially in CNC (Computer Numerical Control) machining. Titanium, prized for its strength and…

- Feed Rate And Cutting Speed: What’s The Difference In CNC Machining

CNC machining is a subtractive manufacturing process that utilizes programmed codes to control the movement of the tool axis. These codes encompass cutting parameters such as tool movement, spindle speeds,…