Leveraging Cobalt Chrome for Medical Device CNC Manufacturing

Cobalt-chrome (CoCr) is a hard, scratch-resistant metal that has gained significant attention in the medical device manufacturing industry, owing to its high degree of wear resistance and biocompatibility. This versatile material is ideal for constructing orthopedic implants, dental prosthetics, and surgical instruments among other applications. Critical features including high mechanical strength, excellent corrosion resistance, alongside an ability to withstand recurrent sterilization procedures make CoCr particularly favourable for medical use.

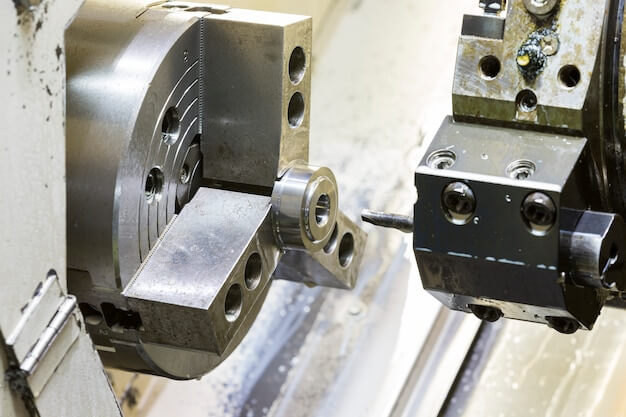

In recent years, Computer Numerical Control (CNC) manufacturing or precision machining has emerged as the primary method for creating complex geometries and minute details on CoCr devices efficiently. The benefits of using such advanced technology include extreme accuracy, scalability, adaptability which contribute significantly to improving patient outcomes by enabling personalized treatment options. However, leveraging this cutting-edge technology does come with potential challenges primarily related to tool wear due to the extremely tough nature of CoCr as well their relatively high costs compared to traditional manufacturing methods; nevertheless, these issues can be mitigated through careful planning and optimal resource utilization.

- Mechanical Strength: Withstand substantial load and stress making it suitable for weight-bearing implants such as hip and knee replacements.

- Highly Corrosion Resistant: Offers outstanding resistance against body fluids, reducing instances of rejection by the human body.

- Ability to endure multiple sterilization cycles: This makes CoCr desirable from a hygiene aspect, critical in any medical application.

- Precision and Detail: By utilizing CNC technology, intricate details can accurately be machined onto CoCr base materials, paving new avenues across various applications in the medical field.

Understanding the Basics: CNC Manufacturing with Cobalt Chrome

When considering CNC manufacturing with cobalt chrome, it’s important to understand:

- Properties and characteristics of cobalt chrome

- Applications of cobalt chrome in medical device manufacturing

- Considerations for machining cobalt chrome

Advantages of Using Cobalt Chrome for Medical Device CNC Manufacturing

Cobalt chrome, owing to its unique properties, brings a plethora of advantages in the manufacturing of medical devices through Computer Numerical Control (CNC). Characterized by its imputed robustness and exceptional resistance to wear and corrosion, it stands as an extraordinary material of choice. Cobalt chrome exhibits high durability that can withstand intense physical stress – a necessary feature for materials utilized in crafting long-lasting implants.

- Durability: Cobalt chromes are characterized by their high endurance, capable of tolerating substantial physical stresses which make them ideal for use in making durable medical implants.

- Resistance to Wear and Corrosion: It possesses excellent resistant qualities against both wear and corrosion – another vital parameter when considering lifecycle and performance of implanted medical devices.

- Other Advantages: Along with durability and resistance features, cobalt chrome retains its form at higher temperatures; showcases strong adherence when paired with ceramic or diamond-like carbon coatings, enhancing its prospects further in medical device sector.

To illustrate these points, consider a hip replacement implant, where endurance, minimal wear, and non-corrodibility hold critical importance. The longevity of such implants is largely determined by resisting active-physical motion-induced wear; towards this end, cobalt chrome’s distinctive traits significantly augment the life and functionality of these prosthetics.

Potential Drawbacks of Cobalt Chrome in CNC Manufacturing

While cobalt chrome garners admiration for its impressive attributes including corrosion resistance, biocompatibility and exceptional strength, it does possess certain drawbacks tied to its use in CNC manufacturing. The hardness of the material stands as a significant setback causing multiple challenges during machining processes due to increased tool wear and slower operating speeds. This extended process duration correlates directly with higher operational expenses resulting from additional time and resources required.

- The high degree of strength that makes cobalt chrome advantageous also contributes to its primary drawback: extreme hardness. This not only increases the risk of tool breakage but also requires frequent replacement or maintenance of cutting tools which further escalifies production costs.

- Sourcing of cobalt chrome can be problematic considering cost implications; unlike common materials such as aluminium or stainless steel, cobalt chrome is considerably more expensive. It impacts significantly on raw material costs affecting the overall manufacturing budget.

In conclusion, despite various benefits offered by cobalt chrome within medical CNC manufacturing field, careful consideration should be given when assessing potential difficulties and cost implications associated with the utilization of this material.

Comparing Alternatives to Cobalt Chrome in Medical Device CNC Manufacturing

In the field of medical device manufacturing using CNC (Computer Numerical Control) technology, several materials stand as potential options besides cobalt chrome. Stainless steel is widely used due to its strength and durability. Moreover, titanium, known for its lightweight alongside good mechanical properties and corrosion resistance, finds extensive usage in this sector. Additionally, plastics such as PEEK, touted for flexibility and cost-effectiveness, comprise an alternate category.

An analysis comparing cobalt chrome with these alternatives delivers insights from various dimensions. With regard to strength, cobalt chrome outperforms stainless steel; however, given the superior weight-to-strength ratio of titanium, it often emerges as a better choice for load-bearing applications. Concerning durability, both cobalt chrome and titanium exhibit excellent long-term performance. Yet, while stainless steel also offers respectable toughness, susceptibility to corrosion may limit its lifespan under certain circumstances.

A final dimension vital to consider is cost-effectiveness. Herein, notwithstanding their benefits, cobalt chrome and titanium tend to be costly to acquire and machine, making them less suitable for large-scale or budget-limited projects. Conversely, PEEK plastic, although not on par with metals regarding resilience, can be an economically viable alternative that provides ample performance for lighter duty applications.

Other Articles You Might Enjoy

- Exploring Bead Blasting in CNC Machining(torsion snap joint Uriah)

Bead blasting is an essential process within the broader umbrella of CNC (computer numerical control) Machining. Understanding its role and functions can provide a unique perspective on manufacturing and production,…

- Precision CNC Machining Services for Aerospace: Specializing in Aluminum

Introduction to Precision CNC Machining Services in Aerospace Precision CNC (Computer Numerical Control) machining is a modern manufacturing technique that uses computer-controlled machine tools to create intricate parts with extreme…

- Challenges and Solutions in CNC Machining of Hardened Steels for Tool and Die Making

Introduction to CNC Machining and the Challenges of Hardened Steels CNC machining is a crucial process in tool and die making, heavily relied upon for its versatility and precision-driven manufacturing…