Differences Between Traditional Drilling and Helical Milling Processes

As a new hole machining method, helical milling technology offers the advantages of stable cutting, lower cutting forces on the tool, and the ability to meet precision requirements in a single operation. This technology has become a hot and challenging topic in material processing research both domestically and internationally. So, how do traditional drilling and helical milling processes differ?

1. Traditional Drilling Process

Traditional drilling has the following characteristics:

Firstly, in the conventional drilling process, the spindle center’s linear speed is zero, meaning the drill bit center does not participate in cutting. The material in the center region of the workpiece must be completely removed by the downward thrust of the drill, resulting in a significant Z-axis force on the drill bit. This leads to rapid tool wear and failure, especially when machining hard-to-machine materials like titanium alloys.

Secondly, traditional drilling is a continuous cutting process where the cutting edge is always in contact with the workpiece, leading to high contact temperatures. Titanium alloys have poor thermal conductivity, and the continuous cutting process causes temperature accumulation, accelerating tool wear and failure, and reducing surface quality.

Thirdly, the chip evacuation method in traditional drilling also contributes to tool failure. Chips are evacuated through narrow slots in the drill bit, which is slow, and since most cutting heat is carried away by the chips, inadequate heat dissipation leads to heat accumulation on the workpiece and tool, accelerating tool wear and failure.

Additionally, when chips are in direct contact with the machined hole surface, they can scratch it, affecting the surface quality. Generally, traditional drilling cannot meet the precision requirements of the aerospace industry without additional processes to ensure hole surface quality, reducing efficiency and increasing costs. From a technical and economic perspective, traditional drilling is no longer suitable for the aerospace industry.

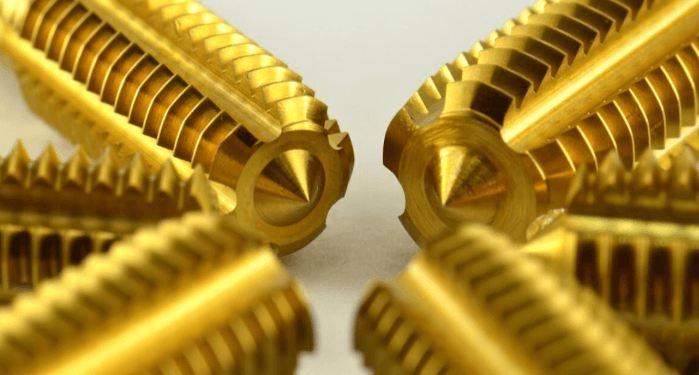

2. Helical Milling Process

Compared to traditional drilling, helical milling uses a completely different approach. Helical milling involves the spindle’s “rotation” and “revolution” around the hole center, creating a unique motion pattern that defines its advantages.

Firstly, the tool center follows a helical path rather than a straight line, meaning the tool center does not coincide with the hole center, resulting in an eccentric machining process. The tool diameter differs from the hole diameter, allowing a single tool to machine a series of different diameter holes, breaking the limitation of one tool per hole diameter in traditional drilling. This increases efficiency and significantly reduces the number and variety of tools needed, lowering costs.

Secondly, helical milling is an intermittent cutting process that aids in tool heat dissipation, reducing the risk of tool wear and failure due to temperature accumulation. Importantly, it improves coolant use, allowing for minimal lubrication or even air cooling, making it an environmentally friendly process.

Thirdly, the eccentric machining process provides ample space for chip evacuation, eliminating chip evacuation as a major factor affecting hole quality. This technology has broad development potential and market prospects, though its machining mechanisms require further study.

3. Advantages of Helical Milling

● Improved Hole Quality and Tool Life

Helical milling significantly enhances hole quality and strength compared to traditional drilling. It is an intermittent cutting process with lower cutting forces, resulting in burr-free holes. The tool diameter is smaller than the hole, allowing for smooth chip evacuation and significantly reducing surface roughness. When machining composite materials, it eliminates issues like delamination, peeling, and poor surface quality caused by dull drill tips in traditional drilling.

Traditional drill bits have low cutting efficiency at the center and are prone to rapid wear due to heat accumulation, resulting in shorter tool life. Helical milling, with its lower cutting forces, significantly extends tool life.

● Shortened Development Cycle and Cost Savings

Using helical milling technology in the manufacturing of aircraft or other heavy machinery can significantly shorten the development cycle and reduce costs.

Helical milling can machine different diameter and complex-shaped holes with the same tool, saving the need for countersinking, reaming, and other processes in traditional methods. This reduces the variety and number of tools required.

Throughout the development cycle, helical milling can eliminate many steps (like deburring, reaming, and cleaning coolant after disassembly and reassembly), greatly shortening the machining cycle.

● High Degree of Automation

Achieving higher automation levels is another way to reduce machining costs. Helical milling’s low cutting forces make it suitable for industrial robot applications. Traditional drilling, with its high axial forces, is unsuitable for such applications.

● Promoting New Material Use

Using new materials in aircraft components is a clear trend, with materials like titanium alloys and composites being widely used. The development and use of these materials require suitable machining processes. Research shows that helical milling has significant advantages over traditional drilling for hole machining.

Helical milling can machine high-quality holes of different diameters with a single tool, reducing tool change time and eliminating the need for finishing operations, greatly improving efficiency. Given its advantages, many companies, especially in the aerospace and mold industries, are adopting helical milling in production.

With the promotion and application of this technology, traditional drilling tools will gradually be phased out, and new milling devices will become more common in machining workshops.

Other Articles You Might Enjoy

- Precision Aluminum Machining for Aerospace: Custom CNC Services

Precision Aluminum Machining for Aerospace: Custom CNC Services In the world of manufacturing, precision aluminum machining plays a pivotal role, particularly in aerospace industries where superior precision is required. As…

- How Do You Optimize CNC Milling Processes for Titanium Parts?

What Are the Critical Considerations for Milling Titanium Effectively? Titanium is an essential material in many industries due to its excellent properties, but these same properties also make it difficult…

- CNC Milling vs CNC Drilling? which one to Choose?

Introduction In the context of manufacturing and industrial applications, Computer Numerical Control (CNC) processing plays a crucial role. Two such techniques integral to these operations are CNC milling and drilling.…

- Understanding CNC Machining: An In-Depth GuideThe Art of Precision: Exploring CNC Milling Processes

Understanding CNC Machining: An Integral Process in Modern Manufacturing CNC (Computer Numerical Control) machining is a critical process in today's advanced manufacturing landscape. It refers to the automated control of…

- Using the Right Milling Technique: Down Milling vs. Back Milling

In the world of CNC milling, experts employ a myriad of techniques to maximize the capabilities of their CNC machines. These techniques are tailored to the size, shape, features, and…

- Basic Knowledge of CNC Turning-Milling Compound Machining

Due to the different CNC systems configured on CNC milling machines, the instructions used vary in definition and function, but their basic functions and programming methods remain the same

- Precision Aluminum Machining for Aerospace: Custom CNC Services

Precision Aluminum Machining for Aerospace: Custom CNC Services In the world of manufacturing, precision aluminum machining plays a pivotal role, particularly in aerospace industries where superior precision is required. As…

- How Do You Optimize CNC Milling Processes for Titanium Parts?

What Are the Critical Considerations for Milling Titanium Effectively? Titanium is an essential material in many industries due to its excellent properties, but these same properties also make it difficult…

- CNC Milling vs CNC Drilling? which one to Choose?

Introduction In the context of manufacturing and industrial applications, Computer Numerical Control (CNC) processing plays a crucial role. Two such techniques integral to these operations are CNC milling and drilling.…

- Understanding CNC Machining: An In-Depth GuideThe Art of Precision: Exploring CNC Milling Processes

Understanding CNC Machining: An Integral Process in Modern Manufacturing CNC (Computer Numerical Control) machining is a critical process in today's advanced manufacturing landscape. It refers to the automated control of…

- Using the Right Milling Technique: Down Milling vs. Back Milling

In the world of CNC milling, experts employ a myriad of techniques to maximize the capabilities of their CNC machines. These techniques are tailored to the size, shape, features, and…

- Basic Knowledge of CNC Turning-Milling Compound Machining

Due to the different CNC systems configured on CNC milling machines, the instructions used vary in definition and function, but their basic functions and programming methods remain the same

- Hard Milling vs. Soft Milling in CNC: Material Considerations and Strategies

Introduction to Milling in CNC Manufacturing Milling, a fundamental process in Computer Numerical Control (CNC) manufacturing, plays an integral role in the production of diverse components across various industries. This…

- Why Is CNC Milling Preferred for Manufacturing Precision Titanium Parts?

Titanium is renowned for its exceptional properties, making it a preferred material for manufacturing precision parts in various industries such as aerospace, medical, and automotive.

- Introduction to Precision Parts Machining: Cutting and Special Processes

Precision parts cutting machining primarily includes precision turning, mirror grinding, and lapping. Using finely ground single-crystal diamond tools on precision lathes, ultra-fine turning is performed with a cutting thickness of…

- What is Micro Milling?

The ever-changing needs of the market necessitate constant updates and advancements in manufacturing technology. In order to maintain a competitive edge, manufacturers must keep pace with these changes or risk…

- CNC Machining: Metals, Processes and More( rivets Dolores)

In the world of CNC (Computer Numerical Control) machining, various materials are used depending on the type of product being produced. Two such commonly used metals are aluminum and titanium.…

- Understanding Bead Blasting in CNC Machining(face milling Rex)

Bead blasting, an abrasive process used within various manufacturing industries, plays a critical role particularly with Computer Numerical Control (CNC) machining to create precise, smooth finished components. Whether it’s for…

- Revolutionizing Renewable Energy with CNC Machined Components

Introduction: Renewable Energy and CNC Machined Components Renewable energy harnesses power from natural sources such as the sun, wind, and water, making it a sustainable and eco-friendly alternative to traditional…

- Is Copper the Right Choice for Electrical Component CNC Machining? A Detailed Analysis

CNC Machining of Electrical Components Utilizing Copper In the field of electrical engineering, Computer Numerical Control (CNC) machining plays an integral role, particularly in the development and manufacturing of electrical…

- Rapid Prototyping with CNC Machining: High-Quality Stainless Steel Parts

Rapid Prototyping and CNC Machining: A Brief Overview Both Rapid Prototyping and Computer Numerically Controlled (CNC) Machining represent transformative technologies within the realm of manufacturing. Rapid Prototyping refers to techniques…

- Custom CNC Machining Services: When to Choose Low Volume over High Volume Production?

Introduction to Custom CNC Machining and Volume Selection in Production Custom CNC machining is a technically advanced process that involves the use of computerized machinery to design, produce, and finish…

- CNC Machining Brass vs. Bronze: Cost, Properties, and Applications Showdown?

Introduction to CNC Machining Brass vs. Bronze: Cost, Properties, and Applications Showdown? In this article, we delve into the debate between brass and bronze machining for an important manufacturing process…

- Decoding the Process of CNC Bead Blasting(milling machining Ted)

Bead blasting is an essential subset and technique used in Computer Numerical Control (CNC) machining. It involves the process of removing surface deposits by applying fine glass beads under high…

- High-Speed vs. Conventional CNC Milling: Material and Application Considerations

CNC Milling: An Overview of High-Speed vs Conventional Methods Computer Numerical Control (CNC) milling is a machining process that plays an invaluable role in producing intricate parts for various applications.…

- Difference Between CNC and Manual Machining

Humans do not like change. Some people were unwilling to let go of their slide rules after calculators were created. While CNC machining has been around for decades, some still…

- Innovative CNC Machining for Complex Surgical Tools

Introduction to CNC Machining and its Significance in Surgical Tools Manufacturing CNC machining, an acronym for Computer Numerical Control machining, plays a significant role in the manufacturing world. Being an…

- Exploring the Limits of CNC Machining with Exotic Metal Alloys

Introduction: CNC Machining and Exotic Metal Alloys CNC machining involves the use of computers to control machine tools, enabling precision manufacturing. A critical aspect of this technology lies in material…

- Prototype CNC Machining Services: Custom Aluminum Solutions

Introduction to Prototype CNC Machining and Custom Aluminum Solutions Prototype CNC (Computer Numerical Control) machining is a manufacturing technique that entails the use of pre-programmed computer software to dictate the…

- How Does CNC Milling Enhance the Production of Titanium Parts?

What Are the Unique Challenges of Milling Titanium? Titanium is a highly desirable material in many industries due to its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. However, its unique…

- Unveiling the Power of Bead Blasting in CNC Machining(milling machining Cliff)

In the world of CNC machining, an unfathomable array of processes co-exist, each serving a distinct purpose that crucially contributes to the final product's quality. Among this plethora, 'bead blasting'…