Understanding CNC Machining in the Aerospace Industry and the Importance of High-Performance Materials Selection

The aerospace industry widely utilizes Computer Numerical Control (CNC) machining for manufacturing sophisticated components. This high precision production method ensures superior repetition, complexity and adherence to stringent tolerances that are essential for aerospace applications. However, successful CNC machining does not depend on precise tooling alone; it is equally reliant on the selection of appropriate materials.

- High-performance materials provide resilience, strength, and withstand extreme conditions,

- They offer attributes like resistance to wear and tear, corrosion or thermal deformity,

- They perform under varying pressures, temperatures and can endure significant mechanical stress without affecting functionality.

Selecting these premium-grade materials becomes a pivotal aspect when ensuring safety, reliability and longevity in aircraft operations. Henceforth, understanding the dynamics of CNC machining within the context of the aerospace industry, along with the crucial role of material choice, sets the foundation for producing top-tier aerospace components.

Fundamentals of CNC Machined Aerospace Components

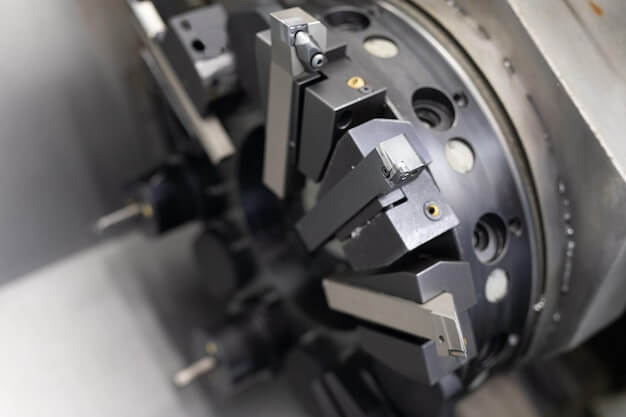

CNC-machined aerospace components play a crucial role in the aerospace industry. These are precision-engineered parts for aircraft and satellites, created using Computer Numerical Control (CNC) equipment that offers high accuracy levels. Examples include turbine blades, structural airframe parts, or intricate fuel system components. The primary function of these components is to enhance the overall performance and efficiency of an aircraft.

- Turbine Blades: Crucial for the engine’s operation, controlling the flow of gases.

- Airframe Parts: Provide structure and stability to the whole aircraft.

- Fuel System Components: Ensure the proper delivery of the fuel within the aircraft engine for effective propulsion.

The materials used for these components need to hold up under extreme conditions such as high temperatures, various pressures, and rapid mechanical stresses. Therefore, selecting high-performance materials addresses essential safety considerations and durability within the industry.

High-Performance Materials Used for CNC Machined Aerospace Parts

When it comes to CNC machining aerospace components, selecting the right materials is crucial for achieving high-performance and reliable parts. Here are some key points to consider:

Lightweight Metals:

- Titanium: Titanium is a popular choice in aerospace CNC machining due to its high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand high temperatures.

- Aluminum Alloys: Aluminum alloys are lightweight and offer good strength and corrosion resistance. They are commonly used in aerospace applications where weight reduction is critical.

High-Temperature Alloys:

- Nickel-Based Alloys: Nickel-based alloys, such as Inconel, are known for their exceptional heat resistance and mechanical properties. They are suitable for components exposed to high temperatures, such as turbine blades and exhaust systems.

- Cobalt-Based Alloys: Cobalt-based alloys, like Stellite, exhibit excellent wear resistance and high-temperature strength. They are often used in aerospace applications that require resistance to abrasion and extreme conditions.

Composite Materials:

- Carbon Fiber Reinforced Polymers (CFRP): CFRP composites offer high strength-to-weight ratios, excellent fatigue resistance, and low thermal expansion. They are commonly used in aerospace structures, such as aircraft wings and fuselages.

- Fiber-Reinforced Plastics (FRP): FRP composites, including fiberglass, provide good strength and stiffness while being lightweight. They are suitable for various aerospace applications, including interior components and fairings.

By selecting high-performance materials for CNC machining aerospace parts, manufacturers can ensure the durability, efficiency, and safety of aircraft components. To explore CNC machining services that offer expertise in machining high-performance materials for aerospace applications, you can visit our Materials page.

Factors to Consider When Selecting Materials for CNC Machined Aviation Components

In selecting materials for CNC machined aerospace parts, certain consideration must be at the forefront. Initially, one has to evaluate the mechanical properties of the potential materials which includes its strength, durability and weight. For instance, titanium might be an ideal material due to its high strength-to-weight ratio which makes it durable yet lightweight – essential in aerospace components. The a. thermal characteristics is another factor that cannot be overlooked, chiefly the heat resistance and conductivity. Aerospace components are exposed to extreme temperatures thus necessitating materials with excellent heat resistant capabilities like Inconel alloys. Finally, materials utilized should possess superior abilities to resist corrosion c., as these parts will be subjected to harsh elements and conditions. Stainless steel could make a practical choice because of its known corrosion resistance property. Making keen considerations on these factors enables optimal performance and longevity of the machined aerospace components.

Why Material Selection Matters

The material selection is a critical aspect in CNC machined aerospace components production as it profoundly influences the efficiency, cost-effectiveness, and longevity of parts. For instance, materials like titanium and aluminum alloys are popular selections due to their lightweight nature that enhances fuel efficiency by reducing overall aircraft weight.

- Efficiency: High-performance materials do not deteriorate rapidly even when exposed to extreme conditions. This feature plays a pivotal role in parts’ performance ensuring optimal operational efficiency.

- Cost-Effectiveness: The right choice of material can significantly reduce maintenance costs. Durable materials save on recurrent replacements or fixes associated with substandard ones thereby guaranteeing cost-effectiveness.

- Longevity of Parts: Advanced high-performing materials have increased lifespan further pushing down maintenance schedules and costs, contributing positively to the longevity of the parts.

In summary, comprehensive considerations around material options will determine whether the produced CNC aerospace parts meet all necessary standards for safety, maintainability, and competitiveness within this demanding industry.

Choosing a Supplier for Aerospace Component Manufacturing

Selecting the right supplier for aerospace component manufacturing is crucial to achieving high-performance CNC machined aerospace components. Primarily, the choice should pivot on three vital considerations: quality control measures, certification compliance, and technical capabilities.

- Quality Control Measures: Ensure that potential suppliers uphold stringent quality control standards. These may encompass precision measurements, pervasive material inspections and comprehensive final product checks. A supplier who adheres meticulously to these key quality indicators undoubtedly promises superior products.

- Certification Compliance: Before making your selection, validate if the prospective supplier complies with acknowledged certifications such as ISO 9001 or AS9100. Such alignment not only attests their commitment to quality but also verifies their consent to industry regulations, consequently mitigating risks.

- Technical Capabilities: The supplier’s technical skills and capabilities form a critical point of deliberation too. Scrutinize their prowess in advanced machining technologies like Multi-Axis CNC Machining, EDM (Electrical Discharge Machining) or others specifically relevant to your project requirements. To illustrate, a supplier adept at Multi-Axis CNC could potentially deliver complex structures swiftly and accurately.

Other Articles You Might Enjoy

- Aerospace CNC Machining: What You Need to Know

At present, the global aerospace industry market value has increased by 278.43 billion, an increase of 6.6% compared to 2022. The ultra-high value proves that innovation in the aerospace industry…

- The Science of Selecting CNC Machining Materials for High-Temperature Applications

Introduction to CNC Machining CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated production of complex parts. Its significance is particularly pronounced…

- Polyester materials in aerospace

Introduction to Polyester in Aerospace Polyester is a category of polymers that primarily comprises compounds within the ester functional group. Its chemical composition often includes a mixture of organic units…