Introduction to Precision CNC Machining and Its Relevance in Industrial Automation

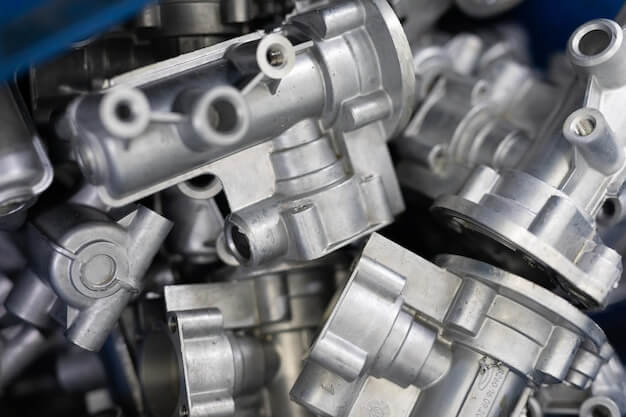

In the sophisticated world of modern industries, precision CNC (Computer Numerical Control) machining plays an integral role. This advanced manufacturing process greatly contributes to industrial automation by providing precise control over complex tasks with minimized human intervention. Superior levels of accuracy, productivity, efficiency, and flexibility offered by CNC machining have turned it into a cornerstone technology shaping the future of various sectors including automotive, aerospace, medical equipment and more.

- CNC machining involves numerically controlled systems that facilitate intricate cutting operations on metal parts, typically automated via computer-aided design (CAD) software programs.

- Industrial automation leverages this precision for automating repetitive or complex processes thereby reducing manual labor efforts and boosting profitability.

- The relevance of advanced CNC machining is growing in today’s industries due to its ability to produce high-quality components at high speed and volume, which directly impact operational cost-effectiveness.

Understanding Precision CNC Machining:

- Step 1: Precision CNC machining is a subtractive process that uses advanced technology and computer programming to cut, shape, and create parts with exact specifications.

- Step 2: The process involves the use of CAD and CAM software to create a design and translate it into manufacturing instructions for the CNC equipment.

- Step 3: To explore precision CNC machining for advanced industrial automation, consider utilizing Precision Machining Service for efficient and reliable manufacturing.

Role of Precision CNC Machining in Industrial Automation

Precision Computer Numerical Control (CNC) machining plays a pivotal role in contemporary advanced industrial automation. This is primarily due to its capacity for executing complex manufacturing processes with remarkable accuracy and consistency, reducing manual intervention considerably.

CNC technology finds ample applications across various industries. The automotive industry, for instance, relies heavily on precision CNC machining for the fabrication of engine components and other intricate parts that demand high levels of exactness. Similarly, the aerospace industry utilizes this technology routinely for creating components that work within tight margins of error.

- In the medical device manufacturing sector, precision CNC supports the production of highly precise devices such as implants or surgical instruments, therefore ensuring patient safety and treatment effectiveness.

- The electronics industry exploits CNC’s precision to manufacture minutely detailed circuit boards and microscopic smartphone components.

Conclusively, the aforementioned sectors and examples underline the significant impact precision CNC machining has made on driving efficiency and quality within modern automated industries.

Advantages of Precision CNC Machining for Advanced Industrial Automation

The integration of precision CNC machining in advanced industrial automation exhibits numerous advantages. It enhances the speed, accuracy, and productivity of mass manufacturing, reducing waste while maintaining strict adherence to design specifics. Automated factories leveraging this technology have reported significant leaps in production efficiency.

A real-world case that exemplifies these benefits can be seen at Tesla’s Gigafactory, where CNC machines are actively used in producing electric vehicle components with flawless precision at high volume. Enhanced by enhanced machine-to-machine communication through IoT integration, the factory has observed a remarkable increase in production output per day. This illustrates just one example of how precision CNC can drive considerable productivity enhancement in modern automated factories:

- Increased Productivity:The use of precision CNC machining amplifies the rate and levels of production since it can run consistently without requiring frequent halts, substantially elevating manufacturing output.

- Improved Accuracy & Quality:Precision CNC machining guarantees consistent part manufacture with a nearly zero margin of error, thus upholding excellence throughout the production process.

- Reduced Waste:Such improved precision also cuts waste from manufacturing operations, contributing to environmentally conscious and cost-effective processes.

- Enhanced Flexibility:CNC machinery can swiftly adapt to alterations in design specifications, making it well-suited for an evolving product line or custom orders.

Challenges in adopting Precision CNC Machining for Industrial Automation

The adoption of Precision Computer Numeric Control (CNC) machining in fully automated factories presents noteworthy challenges. A potential pain point rises from the required paradigm shift in operational processes. These machines necessitate adaptation to new procedures and systems, which can be met with resistance by factory workers unaccustomed to high-tech equipment. Moreover, integrating these sophisticated tools demands extensive alterations to existing infrastructure, leading to increased production downtime and associated costs.

Numerous solutions are being explored to overcome these setbacks:

- Leveraging specialized training programs tailored for factory employees helps facilitate smoother transitions, ensuring machine operators become proficient in managing advanced CNC machinery.

- To placate risks linked to infrastructure changes, phased implementation plans where installations occur during off-peak hours or segmented sections can reduce disruptions to ongoing operations.

- Furthermore, collaborating with knowledgeable vendors who provide continuous support throughout the integration process will significantly mitigate common issues encountered during installation and operation periods.

In conclusion, although adoption of precision CNC machinery poses certain obstacles, effective planning and execution strategies have proven to counteract these hurdles enabling enhanced industrial automation.

Conclusion: The Future of Precision CNC Machining

In conclusion, precision CNC machining has undeniably laid the foundation for future smart manufacturing. Its importance is underscored by its ability to enhance efficiency, reduce human error, and enable high-dimensional accuracy in producing intricate components. With burgeoning technological advancement, there are all indications that the field will continue evolving leaps and bounds.

- The immediate focus lies on Industry 4.0 – interconnecting automation with advanced analytics, resulting in increased productivity while retaining quality.

- On another front, additive manufacturing or 3D printing may collaborate with CNC machining to streamline processes further, without compromising the strengths of either method.

- Predictive maintenance using artificial intelligence and machine learning technology can spot potential issues before they become major setbacks.

These advancements reflect just a tip of what lies ahead in this field of industrial automation. Precision CNC machining will undoubtedly continue showing its robust capabilities, unravelling unprecedented possibilities in the pursuit of enhancing productivity and refinement in our industries.

Other Articles You Might Enjoy

- CNC Machining Aluminum Alloys: A Guide to Best Practices and Material Choices?

Introduction to CNC Machining and Aluminum Alloys CNC (Computer Numerical Control) machining is a manufacturing process that employs pre-programmed software to dictate the movement of factory machinery and tools. This…

- Unlocking New Possibilities in CNC Machined Titanium Medical Devices

Introduction to CNC Machined Titanium Medical Devices The prevalence of CNC machined titanium medical devices in the healthcare sector demonstrates their immense significance and usefulness. This technology furnishes an essential…

- CNC Aluminum Machining Services: Advanced Techniques for Perfect Parts

CNC Aluminum Machining Services In the current manufacturing landscape, CNC aluminum machining services play a pivotal role. CNC which simply translates to 'Computer Numerical Control', is an advanced technique used…