In the world of manufacturing, precision is paramount. One widely adopted method known for its precision is CNC machining. An integral subcomponent in the broader spectrum of CNC (Computer Numerical Control) machining operations remains bead blasting. Being a surface treatment process, bead blasting uses tiny beads to make finished parts smooth or clean, which enhances their look and functionality. This article will delve into this unique process that combines technology and grit; understanding the principle behind it, how it fits into the larger scope within CNC machining, and why it’s vital.

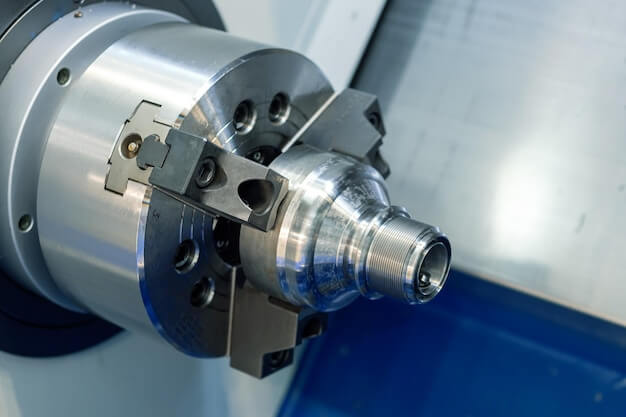

To fully understand the essence of bead blasting, one must first comprehend the fundamentals of CNC machining. This operation thrives on computer control where pre-programmed software dictates the movement of machinery and tools. The result is meticulously intricate components produced quickly and accurately without manual interference. From milling, turning, grinding, drilling, to bead blasting, CNC machining caters to several functions that contribute to the production of precision-demanding parts across multiple industries like aerospace, medical, automotive and more.

Bead blasting falls under finishing processes in CNC machining. Though all stages of the manufacturing procedure play critical roles in shaping end products’ quality, the final phases –including bead blasting– are essential as they influence both performances, aesthetics, and lifetime of these parts.

So now begs the question: what exactly happens during bead blasting? Basically, small glass beads get propelled at high velocity towards the material’s surface, often metals or other rigid materials. In simpler terms, imagine sand particles being hosed onto your driveway, strong enough to sweep away any debris without damaging the concrete itself. That’s pretty much bead blasting in layman’s language but instead of sand, we use small spherical glass beads, and rather than a yard, we have a component’s surface.

The beads create an even, smooth finish by resisting bending, offering stillness throughout the application. This results in a seamless, satin-like surface free from blemishes or scales that may otherwise render the machine part useless. Various factors like bead composition, size, blasting pressure and duration can influence the outcomes of this process.

The advantages of bead blasting go beyond mere aesthetics; it offers functional benefits as well. For starters, since the beads are not abrasive, they don’t excessively wear out the targeted components, extending their durability. When directed at an old piece, bead blasting eliminates rust and other unwanted substances to make it look new or ready for repainting. It also aids in uncovering any weaknesses hidden beneath dirt layers by giving a bright finish, hence allowing visual inspection of produced parts.

Furthermore, bead blasting is advantageous due to its environmentally-friendly nature. The beads used are typically recyclable; thus reducing waste. Moreover, because no hazardous chemicals get involved in the process, operational safety gets greatly enhanced.

Incredible as it might seem, bead blasting is a relatively simple but vitally effective step in CNC machining procedures. By pushing tiny glass beads at high speeds towards finished pieces’ surfaces, manufacturers are able to spruce up their products quickly and cost-effectively. Remember though, while the function of bead blasting within the broader spectrum of CNC machining processes might appear trivial, its contributions to product quality and subsequent reputation of your brand on the competitive market scale should never be underestimated.

To conclude, CNC machining services offering bead blasting deliver speed, precision, and sustainability with impressive finishing results – forging smoother paths toward overall manufacturing excellence. Bead blasting remains a testament to how minor intricate details, when handled correctly using superior technology, can cast considerable impacts that ripple across the industry’s landscapes.

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Inconel vs. Monel for CNC Machining: Understanding the Differences and Applications?

Inconel vs. Monel: Definitions and Primary Uses In the realm of CNC machining, two materials that are often compared due to their unique properties are Inconel and Monel. Inconel is…