Introduction to Custom CNC Machining For High-Quality Lighting Fixtures

In this article, we aim to explore the integral role of custom Computer Numerical Control (CNC) machining in the production of high-quality lighting fixtures. The focus will be on analyzing how advanced manufacturing processes enhance the creation of intricate designs, precision and durability of lighting fixtures. As such:

- We’ll delve into the intricacies of CNC machining operations that foster efficient material use and reduce waste.

- The discussion will also cover the versatility of CNC machines in accommodating various materials ranging from metals to plastic used in making lighting fixtures.

- A special attention will be given to high-speed CNC machining which ensures faster delivery times without compromising quality.

By providing insightful examples, the paramount importance of incorporating customised CNC machining techniques when manufacturing state-of-art lighting fixtures would be underscored in detail.

The Concept of Custom CNC Machining

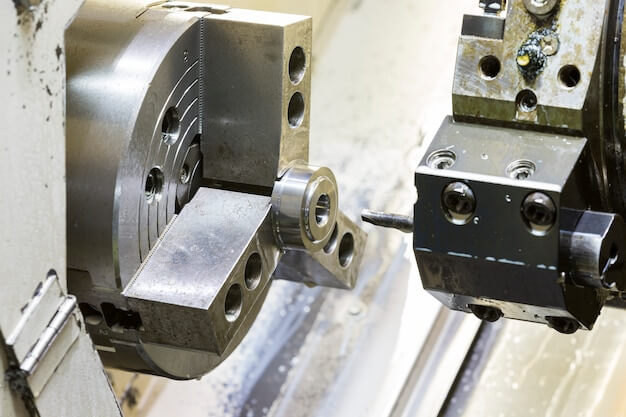

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilizes pre-programmed computer software to direct the movement of factory machinery and tools. It makes crafting complex three-dimensional shapes possible on a single set of instructions, unlike manual machining which requires human intervention at each step.

Custom CNC machining has gained significant importance in various industries due to its precision, efficiency, and capability for mass production. From aerospace components to automotive parts, medical devices to lighting fixtures, custom CNC machining plays an integral role in product development.

In terms of lighting fixture production, custom CNC machining crafts high-quality products by intricately working on different materials like metal and plastic. These tools can carve designs, drill holes, cut patterns, ensuring every piece is exactly alike with unmatched accuracy. This mechanized system also reduces errors associated with manual handling, thereby enhancing overall quality and saving time and cost.

- Efficiency: Provides faster production rates by automating the machining processes.

- Precision: Produces highly accurate parts with a very low margin of error.

- Versatility: Capable of creating intricate designs with multiple materials, including metals and plastics.

- Uniformity: Guarantees consistent quality across all pieces produced.

Custom CNC Machining in Lighting Fixture Production:

- Step 1: CNC machining is utilized to customize the lenses of lighting fixtures, often made of aluminum alloys, to achieve a shiny, mirror-like finish.

- Step 2: Additionally, tough plastics used for the cover of lighting fixtures can be machined to create delicate and intricate shapes, enhancing the overall aesthetic appeal.

Advantages of Using Custom CNC Machining for Lighting Fixtures

The utilization of custom Computer Numeric Control (CNC) machining in the production of lighting fixtures comes with numerous unique advantages. These include enhanced precision, cost-effectiveness and marked speed in manufacturing processes. Utilizing advanced computer programs ensures that intricate shapes and designs can be replicated with maximum accuracy, eliminating any chance of human error. This results in minimal material waste and therefore cost savings.

CNC machining also enables rapid production of parts, offering a much higher pace of operation than traditional manual machining techniques. This expedited process does not compromise quality – ensuring each fixture maintains consistent sizing and proportions to meet customer expectations.

- Precision: Each part is carved based on precise digital measurements reducing margin of error or misfits.

- Cost-effectiveness: Minimized wastage translates into saving costs on erroneous prototypes and fine-tuning models.

- Speed: Automated systems significantly reduce production timeframes making it a quick solution for large scale orders.

An excellent real-world example of these benefits being realized is in the mass-production of bespoke pendant lights used fittingly, in 3D printing factories. The meticulous intricacies of their design required exact cut-outs achieved only through utilizing custom CNC machining. The order necessity prompted quick turnaround times where CNC machines were able to output hundreds of pendants per day, meeting both deadline and budget requirements.

Characteristics of High-Quality Lighting Fixtures and the Role of Custom CNC Machining

In defining high-quality lighting fixtures, several key characteristics come to mind. For one, durability is crucial as long-term usage requires a design that can withstand wear and tear. The fixture should also be easy to install, with straightforward instructions for hassle-free assembly. Additionally, high-quality fixtures display exceptional luminosity and light dispersion for optimum illumination capabilities. They possess excellent thermal management ensuring efficient operation even under continuous use.

Custom CNC machining substantially contributes to these qualities. It ensures precision in creating complex parts, supporting enhanced durability through precise fits and minimal part failures. With automated processes, each product maintains uniform standards, facilitating simple installations. Moreover, custom CNC machining enables tailored designs optimizing light dispersion and placement for maximum luminosity. Lastly, the capability to work with various materials allows effective heat dissipation components leading to better thermal management.

- Durability: Enabled by the precision of CNC machining in creating complex parts

- Ease of Installation: Facilitated by maintaining uniform standards between products via automated processes

- Luminosity and Light Dispersion: Optimized through tailored designs achieved by CNC machining technologies

- Thermal Management: Enhanced due to the ability of CNC machines to work with different materials for effective heat components

Exploring Different Types of Lighting Fixtures Produced Through Custom CNC Machining

Custom CNC machining plays a pivotal role in creating an array of high-quality lighting fixtures, each distinct in design and functionality. First on this list are pendant lights, often designed intricately using CAD software before the CNC machine meticulously mills them into unique hanging pieces. Second, chandeliers sculpted with superior precision from both metallic and acrylic materials are another common product of this technology. Recessed light fixtures, perfect for modern minimalistic interiors, showcase another exceptional utilization of custom CNC machining due to their complex encasing requirements.

- Pendant Lights: These are suspended lights which require meticulous designing that is readily achievable through custom CNC machining.

- Chandeliers: They represent more intricate design patterns which can be accurately replicated by advanced CNC machines.

- Recessed Lights: Custom CNC machines play a crucial role in manufacturing these types of lights owing to the complexities involved in their enclosure designs.

In conclusion, these versatile lighting solutions echo the flexibility of CNC machining while highlighting its potential to transform rudimentary drafts into tangible artistry under optimal conditions.

Challenges and Solutions in Custom CNC Machining for Lighting Fixture Production

The utilization of Custom Computer Numerical Control (CNC) machining in the production of high-quality lighting fixtures is not without its challenges. One common issue manufacturers face pertains to machine programming errors which can result in defective parts, increased material wastage, or even undue wear on tools. Furthermore, improper tool selection may affect the quality, speed, and cost-effectiveness of fixture production. Achieving precise illumination pattern designs also becomes a significant challenge given that intricate geometries require exceptionally accurate machining.

In addressing these problems, utilizing simulation technology before running the actual program can be highly effective in detecting potential mistakes thus minimizing subsequent damage and loss. In the same league, choosing suitable tools considering factors like material type, operation type, and desired cut characteristics would significantly improve the efficiency and final product quality. Moreover, implementing advanced CAM (Computer-Aided Manufacturing) software aids in achieving complex geometrical patterns with precision.

Conclusion

In a nutshell, the primary points touched upon throughout this piece underscore the imperative role that custom CNC machining plays in fabricating high-quality lighting fixtures. The technique aids in improving accuracy, augmenting flexibility, and expediting production speeds – hallmarks of an efficient manufacturing process. Furthermore, CNC machining has its advantages underlined by the capacity to produce intricately designed fixtures with extraordinary precision, all while favorably affecting the overall production cost.

- Accuracy: With CNC machines, design instructions are inputted into a computer program resulting in exact replication with minimal human error.

- Speed: Custom CNC machines can operate continuously over long durations eliminating disruptions hence boosting productivity.

- Cost-effectiveness: The integration of automated processes helps reduce labor costs significantly thereby improving total economic efficiency.

This article is a reaffirmation of the importance and distinct advantages leveraged through the incorporation of CNC Machining in producing unique, top-tier lighting fixtures. Given these desirable properties, it’s manifest that CNC machining continues to be an indispensable part of responsible and modern-day manufacturing.

Other Articles You Might Enjoy

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Exploring Bead Blasting in CNC Machining(cnc machining services china Nicole)

Bead blasting is a process used extensively in the world of computer numerical control (CNC) machining. A standard part of many businesses, bead blasting enriches various products that we use…