CNC Custom Machining: Tailored Solutions for Aluminum and Steel

In the manufacturing industry, Computer Numerical Control (CNC) custom machining plays a critical role in providing tailored solutions to aluminum and steel. It is a sophisticated form of technology utilizing computer software to automate and control machine tools, resulting in highly precise components. This powerful application allows manufacturers to create customized parts with greater speed, accuracy, and repeatability than traditional methodologies.

- Importance: CNC custom machining offers unmatched precision which is paramount in industries like automotive, aerospace, medical equipment, and more. Due to its capabilities, it reduces waste by producing consistent and reliable results, making it both economically and environmentally beneficial.

- Application: In essence, when an object requires intricate detailing or complex geometry that manual operations cannot handle effectively, CNC custom machining steps in. Its application ranges from drilling, grinding, milling to lathing – all to ensure goods adhere strictly to specified measurements and quality standards. An example can be found in the automobile sector where CNC machines are used to manufacture engine parts with absolute precision.

Understanding Materials: Aluminum and Steel

The materials most commonly used in CNC custom machining are aluminum and steel, each possessing unique qualities that suit different manufacturing needs.

Aluminum is recognized for its lightweight properties paired with considerable strength, making it ideal for production purposes. It has excellent machinability, corrosion resistance, and thermal conductivity. Additionally, this material has a high electrical conductivity, hence extensively used in the electronics industries.

- Basic Characteristics of Aluminum:

- Lightweight

- Strong

- Excellent Machinability

- High Corrosion Resistance

- Superior Thermal Conductivity

- High Electrical Conductivity

On the other hand, steel is renowned for its versatility and durability. The alloys can be tailored across a wide range of hardness, toughness, and magnetic permeability among other benefits. They offer varied tolerance to heat treatment and welding criteria based on the element proportions present, thus pleasing the diversified manufacturing requirements.

- Overview of Steel’s Properties:

- Versatile

- Durable

- Customizable Hardness and Toughness

- Variable Magnetic Permeability

- Heat Treatment Tolerant

- Weld-friendly

Custom Solutions with CNC Machines

CNC custom machining provides tailored solutions for various project needs, enhancing productivity and precision in metal fabrication process. It allows you to customize designs based on the specific requirement of each part. Users can program these machines to perform complex tasks that could otherwise require extensive manual labor. For example, if a product requires 100 exact replicas of a steel component, a CNC machine would be programmed with precise information about the parts including measurements and dimensions. The machine then goes to work carving out exactly what has been instructed, with little room for error.

-

The primary benefit of this customization is accuracy coupled with speed. Since these machines are computerized, they deliver not just high-quality outcomes but also significantly reduce turnaround time.

-

In addition to repetition jobs, they’re fantastic for producing unique parts or prototypes because their programming can be adapted easily.

-

The possibilities with CNC machines are almost endless; From car parts to personalized door handles – virtually any intricate design that needs impeccable execution finds reliable solution in CNC custom machining.

Advantages of Using Custom-Machined Parts

Switching to CNC custom machining for aluminum and steel offers several distinct advantages, foremost among them being the high precision it delivers. Unlike conventional manufacturing processes, custom machining ensures exact dimensions every time, eliminating errors that could affect performance. This accuracy not only gives end users confidence in their products but also contributes significantly to upholding a company’s reputation for quality.

Aside from precision, another headline benefit of using custom machined parts is efficient production. The automated nature of CNC machining negates human error and drastically reduces the time taken to manufacture components, even complex ones. The ability to replicate designs quickly without compromising on quality implies faster delivery times – an attribute all manufacturers strive towards.

CNC custom machining also serves as an excellent cost-effective solution owing to significant waste reduction. Traditional operations often result in excess material, substantively impacting costs. In contrast, CNC machines are programmed to use resources efficiently, ensuring minimal wastage. Consequently, reduced expenditures on materials directly translates into savings for the company.

Step-by-step Process of CNC Custom Machining:

- Material Selection: Choose the appropriate material, whether it’s aluminum or steel, based on the specific requirements of the custom part.

- Design Analysis: Conduct a thorough analysis of the design to ensure it aligns with the capabilities of CNC machines and minimizes the need for custom tooling.

- Programming: Utilize advanced computer programming to create precise toolpaths for the CNC machines, optimizing the machining process for tailored solutions.

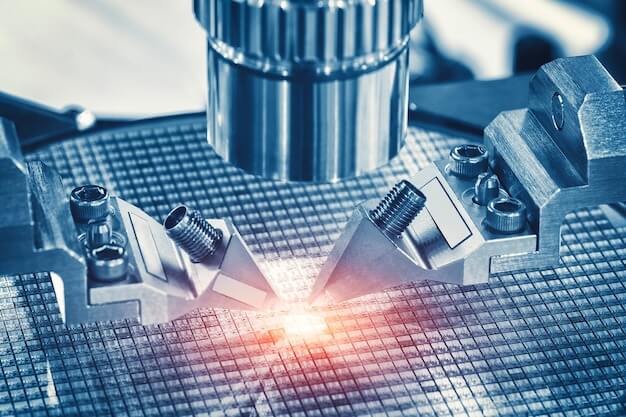

- Machining Execution: Implement the custom machining process using state-of-the-art CNC machines to accurately shape and create the custom-designed parts.

- Quality Assurance: Perform rigorous quality checks to ensure the custom-machined parts meet the highest standards and specifications.

- Service Provider: When seeking tailored solutions for aluminum and steel custom machining, it is essential to partner with a reliable online CNC service that offers expertise in precision machining and proven capabilities in custom part manufacturing.

Insights from Industry Experts: How CNC Custom Machining is Revolutionizing Manufacturing

In the sphere of manufacturing, industry experts universally assert that Computer Numerical Control (CNC) custom machining represents a groundbreaking evolution. Its substantial impact stems from its capacity to allow customization which is critical in today’s competitive industrial landscape. This ability to tailor parts invites greater efficiency and precision – elements that are highly sought after.

-

An excellent instance of an industry reaping enormous benefits from CNC custom machining is the aerospace sector as it requires bespoke components for each aircraft model. By implementing CNC custom machining, they can have precise and error-free pieces rapidly produced that meet exact specifications.

-

Similarly, the medical device industry also illustrates this revolution, where machinery must cater to intricate and patient-specific needs. Consequently, generic solutions just don’t suffice. Therefore, leveraging CNC technology gives them unique parts vital to their operations.

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Breaking Barriers in CNC Machined Aerospace Structures

Introduction: CNC Machining in Aerospace Structures In the aerospace industry, accuracy, reliability and efficiency are paramount. To maintain these standards, modern day aerospace manufacturing heavily leans on Computer Numerical Control…