Bead blasting is an integral process in Computer Numerical Control (CNC) machining, contributing to the finishing touches that enhance both aesthetic and functional aspects of manufactured parts. Whether you’re a seasoned engineer or someone new to the field, understanding bead blasting’s role within this production framework can be incredibly valuable.

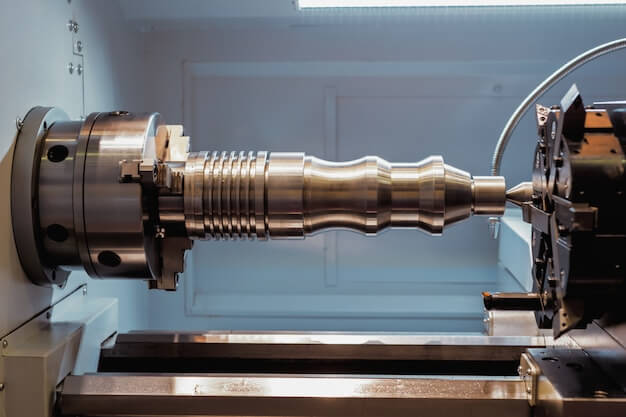

Bead blasting is essentially a peening operation that employs fine glass beads as an abrasive medium under high pressure to clean and finish metallic surfaces. The sheer force of the action allows for precision that is paramount in most machining processes, improving not only the look but also the quality of finished products.

One of the many advantages of using bead blasting in CNC machining lies in its non-destructive character. Traditional metal cleaning methods can cause harm to the surface of components by removing excessive material. In contrast, bead blasting gently scours the surface without leaving visible scratches or causing deformations. This makes it particularly well-suited for delicate and precise tasks such as preparing metallic surfaces for coating and paint application.

When integrated into CNC machining, bead blasting optimizes several operations ranging from cleaning, deburring to creating a desirable texture on the metal pieces. Specifically in CNC machining where precision is key, bead blasting presents itself as a vital actor.

Imagine a scenario where your company specializes in producing CNC machined auto spare parts. Before these parts can be painted or coated, they need perfect surface preparation – free from oils, dirt, burrs, and other contaminants which may hinder adhesion. Here’s where bead blasting comes into play. It removes all these impurities, leaving behind a textured surface ideal for subsequent treatments and achieving long-lasting finishes.

The trade-off between quality and efficiency remains a core concern in any manufacturing setting. Despite its unparalleled benefits, standard bead blasting procedures might consume more time compared to other finishing techniques due to their inherent complexity. Nevertheless, when integrated with CNC machining’s automation, it significantly reduces process time while ensuring high-quality finishes. This blend of quality and efficiency puts bead blasting at the forefront of modern manufacturing.

In terms of application, many industries take advantage of bead blasting in their CNC machining operations. From aerospace engineering to medical equipment manufacturers, the benefits of this technique are heavily recognized. For instance, such a process is used extensively in the automobile industry where parts require uniform texture and optimal cleanliness to be correctly assembled or coated.

It is essential to note that like every other industrial process, the correct utilization of bead blasting requires expertise and knowledge. Making the most out of it relies upon factors like suitable machinery, appropriate bead size selection, and rightly calibrated pressure. These variables need expert handling for best outcomes.

In conclusion, bead blasting has proven to be an efficient and beneficial production method within the CNC machining world due to its precise cleaning capabilities and effective preparation of surfaces for subsequent treatments. Its partnership with CNC machining creates an elevated standard for part finishing procedures – achieving remarkable levels of precision, quality, and productivity. As technology continues to advance, integrating bead blasting applications into automated systems will likely magnify outputs even more, revolutionizing the manufacturing landscape one small, highly accurate piece at a time.

Other Articles You Might Enjoy

- Bead Blasting: The Secret to Quality CNC Machining(cnc machining tools Mavis)

The world of manufacturing has witnessed revolutionary changes with the advent of Computer Numerical Control (CNC) machining. It is a process used in the manufacturing sector that involves the use…

- Understanding CNC Machining: The Bead Blasting Process(cnc machining tools Valentina)

In the world of manufacturing, precision is paramount. One widely adopted method known for its precision is CNC machining. An integral subcomponent in the broader spectrum of CNC (Computer Numerical…

- Understanding Bead Blasting in CNC Machining(cnc cutting tools Evan)

In the realm of computer numerical control (CNC) machining, we often uncover complex processes designed to improve product outcomes. One such procedure that stands out is bead blasting. This technique…