Introduction to Biodegradable Plastics and CNC Manufacturing

The recent years have seen a significant shift towards sustainable resources, bringing biodegradable plastics into the limelight. These eco-friendly materials can decompose naturally over time, reducing our dependence on traditional, non-recyclable plastics. As environmental consciousness grows, so does the demand for these innovative substitutes.

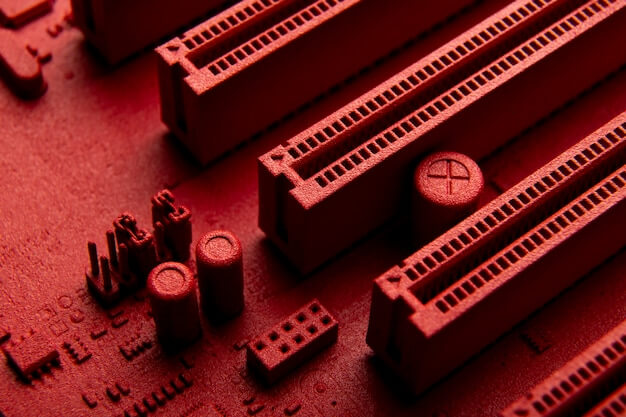

Beside this, Computer Numerical Control (CNC) manufacturing has experienced a rising trajectory in popularity due to its precision, consistency and versatility across multiple industries. This automated process involves preprogrammed computer software dictating the movement of factory tools and machinery, effectively optimizing production processes and overall efficiency.

- Biodegradable Plastics: Friendly to the environment, capable of decomposing naturally without leaving harmful residues.

- CNC Manufacturing: A form of automation involving computer-aided design and drafting that significantly optimizes production, offering remarkable precision and consistency.

Consequently, intersecting biodegradable plastics with CNC manufacturing presents an exciting avenue for industries worldwide. The fusion creates potential opportunities while simultaneously posing unique challenges, particularly catering to today’s increased emphasis on sustainability.

Connection Between Biodegradable Plastics and CNC Manufacturing

The integration of biodegradable plastics into Computer Numerical Control (CNC) manufacturing operations signifies a significant shift towards sustainable production practices. In this context, biodegradable plastics function as eco-friendly alternatives to traditional plastics used in the creation of diverse parts and components. These substances offer numerous advantages, such as reducing environmental pollution while still providing quality goods.

CNC machines have the ability to manage intricate cuts on biodegradable materials with precision and consistency that is equivalent or superior to manual methods. This capability stems from the fact that CNC technology utilizes computer-guided systems in its procedures which guarantees exactness and detail even when working with different shapes and intricate cuts. For instance:

- On applications requiring detailed engraving, automated machines can reproduce designs identically across multiple pieces without errors or inconsistencies.

- In routing processes, where material removal around edges or throughout the surface area is necessary for final processing stages, employing CNC machinery eliminates inaccuracies whilst optimizing cycle times.

Hence, the combination of biodegradable plastic and CNC manufacturing provides opportunities not only to improve productivity but also to foster an environmentally conscious manufacturing ecosystem.

Benefits of Utilizing Biodegradable Plastics in CNC Manufacturing

Utilizing biodegradable plastics in CNC manufacturing offers the advantage of reducing environmental impact, promoting sustainability, and meeting the increasing demand for eco-friendly manufacturing materials.

Challenges with Biodegradable Plastics in CNC Manufacturing

One substantial challenge faced in the application of biodegradable plastics in CNC manufacturing lies in the technological limitations. The machining complexities for these materials are unique, making it hard to achieve consistency and precision during production. For instance, a company called BioCorp struggled to maintain product reproducibility due to fluctuating performances of their CNC machines handling biodegradables. This difficulty manifested due to the inconsistent behavior of biodegradable raw material when exposed to the cutting forces involved in ordinary CNC operations.

Another notable issue relates to investment costs. Switching from conventional plastics to biodegradable alternatives often requires significant upfront investments in new machinery or retrofitting existing systems. A case study by GreenTech, a leading manufacturer, revealed that their initial capital expenditure rose approximately 25% after transitioning towards sustainable options; this increase was attributed mainly to machine adaptations required to accommodate the different physical properties of biodegradable plastics.

Opportunities in Application of Biodegradable Plastic with CNC Manufacturing

With the increasing environmental concerns, there is a significant shift towards more sustainable practices across various industries. One such industry making significant strides to minimize its ecological footprint is Computer Numerical Control (CNC) manufacturing – primarily through the adoption of biodegradable plastics. This transition has demonstrated substantial potential adaptability of biodegradable plastic within the sector.

For instance, the packaging industry, renowned for the excessive use of non-biodegradable materials, has begun transitioning towards these eco-friendly alternatives. It undertakes this by replacing traditional plastics with biodegradable ones in aspects like protective coverings and boxing materials produced using CNC machinery.

- Future market possibilities: The future landscape indicates robust growth projections for the usage of biodegradable plastics in CNC manufacturing. Several studies predict an annual growth rate of 15% for the global biodegradable plastic market over the next five years. Such positive forecasts are supported by burgeoning consumer demands for environmentally friendly products and stringent governmental regulations against single-use plastics.

- Evidence supporting those projections: A Reporting from ‘MarketsandMarkets’ concurs with these views, pointing out that escalating industrialization rates coupled with technological advancements in biodegradable plastic production techniques will boost the demand for these materials in CNC manufacturing.

Conclusion

In conclusion, the incorporation of biodegradable plastics in Computer Numerical Control (CNC) manufacturing presents both opportunities and challenges. On one hand, as reviewed throughout the article, its usage supports environmental sustainability due to its nature-friendly decomposition capabilities. It offers prospects for a greener future in manufacturing by reducing landfill waste and promoting circular economy models. On the other hand, issues concerning durability, cost-effectiveness, and industrial readiness to switch from long-lasting conventional materials were identified.

The move towards biodegradable plastic production may necessitate changes in regulatory frameworks and incentives to promote industry adaptation. Further research is required to address current technical limitations and explore new methods that enhance the efficiency and viability of producing such eco-friendly alternatives. Looking ahead, while significant hurdles remain, the potential abounds for biodegradable plastics transforming CNC manufacturing into an environmentally conscious sector.

Other Articles You Might Enjoy

- Exploring Bead Blasting in CNC Machining(torsion snap joint Uriah)

Bead blasting is an essential process within the broader umbrella of CNC (computer numerical control) Machining. Understanding its role and functions can provide a unique perspective on manufacturing and production,…

- Precision CNC Machining Services for Aerospace: Specializing in Aluminum

Introduction to Precision CNC Machining Services in Aerospace Precision CNC (Computer Numerical Control) machining is a modern manufacturing technique that uses computer-controlled machine tools to create intricate parts with extreme…

- Challenges and Solutions in CNC Machining of Hardened Steels for Tool and Die Making

Introduction to CNC Machining and the Challenges of Hardened Steels CNC machining is a crucial process in tool and die making, heavily relied upon for its versatility and precision-driven manufacturing…