Introduction: CNC Machining in Aerospace Structures

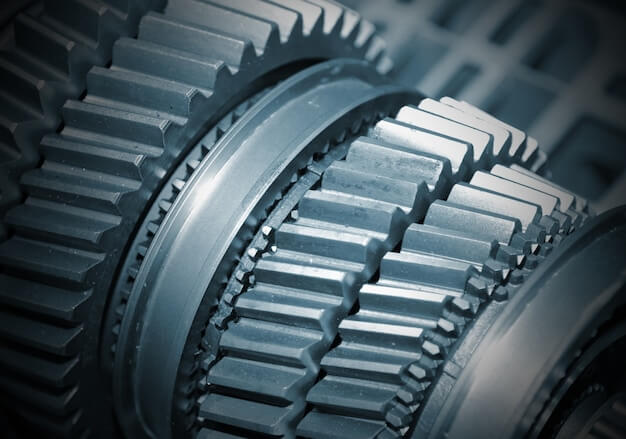

In the aerospace industry, accuracy, reliability and efficiency are paramount. To maintain these standards, modern day aerospace manufacturing heavily leans on Computer Numerical Control (CNC) machining processes. CNC machining, a subtractive process where raw material is removed with precision to create the desired part or component, plays a pivotal role in constructing robust and high-precision aerospace structures such as wings, fuselage, rudder and more. The key elements that make it indispensable include:

- Precision: With tolerances tighter than +/- 0.002 inches, CNC machines deliver high-dimensional accuracy for complex aerospace components.

- Versatility: CNC machines can work efficiently on a manifold of materials typically used in aerospace sector, even those hard-to-machine ones like titanium, Inconel etc.

- Scalability: Being an automated operation, CNC allows production scalability with consistency in quality.

Understanding Aerospace Structures

Aerospace structures, at the most fundamental level, serve as the backbone of any aircraft or spacecraft. These structures are specifically designed and engineered to withstand the intense pressures and stresses experienced during flight operations while also serving various vital functions within each aerospace vehicle. Aerospace structures typically incorporate a wide array of materials in their design including aluminium, titanium, and composite materials. Aluminium is favored for its light yet robust properties; titanium due to its high strength-to-weight ratio and resistance to extreme temperatures; and composites – such as carbon fiber – for their lightness and durability.

These structures play an essential role across all types of aerospace vehicles. For instance, they contribute to the structural integrity of aircraft, providing support and stability during maneuvers. In spacecrafts, these structures must be able to tolerate both the violent vibrations of launch and the harsh environment of space. Without well-crafted and meticulously manufactured aerospace structures, safe and effective aviation and space exploration become impossible tasks. Hence, ensuring that these structures are made using precise CNC machining processes is critical.

Understanding the significance of CNC Machining in Aerospace Structures:

- Aerospace CNC machining involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. It is a manufacturing process that uses kits, components, and assemblies essential for crafts used in the aerospace industry.

- This article provides you with a complete guide to aerospace machining and its importance. online CNC service

- Aerospace CNC machining is essential in manufacturing spacecraft and rockets for space travel. It helps create minute components and ensures precision manufacturing for the safe operation of the spacecraft and the protection of the crew.

Barriers in CNC Machined Aerospace Structures

Aerospace manufacturing is fraught with multiple challenges, principally within the domain of Computer Numerical Control (CNC) machined structures. One such obstacle lies in the high precision required for aerospace components. A slight deviation from the exact specifications can lead to suboptimal performance or system failures. These can have a critical impact on mission success and potentially risk human lives.

Furthermore, another significant barrier looms within the constraints of material handling. The difficulty lies in machining strong, lightweight alloys often used in aerospace applications—namely titanium and aluminum. These materials are challenging to work with due to their characteristics that can cause tool wear, adhesion, chip control problems, and generate excessive heat leading to damage for both tools and parts.

For instance, while processing titanium—a widely preferred choice for its strength-weight ratio—the abrasive nature wears out tools at an accelerated rate. This raises production costs and decreases efficiency. If not accurately managed, these barriers could result in costly delays, compromised structural integrity, safety issues, and potential mission failure.

To triumph over these barriers, there’s a necessity for avant-garde technological improvements and adapted strategies like advanced coolant systems, real-time monitoring, better-optimized cutting parameters, and usage of tougher but more expensive tool materials such as polycrystalline diamond or cubic boron nitride.

Breaking Barriers in CNC Machined Aerospace Structures

The advancement of computer numerical control (CNC) technology has been paramount in overcoming the challenges related to aerospace structures. Various strategies and technological developments have contributed significantly towards betterment in this domain. To begin with, high-speed machining (HSM) offers a solution for time-consuming processes by expediting the crafting of intricate parts.

- An instance where HSM comes into play is in manufacturing turbine blades that demand precision and speed. The implementation of HSM precisely reconstructs and speeds up the crafting process without compromising on quality.

- Next, multi-axis CNC machines are breaking barriers relating to limitations posed by conventional 3-axis systems. For example, complex geometrical designs like airfoil shapes solutions could be seamlessly executed using modern multi-axis CNC machines.

- Lastly, newer material-specific tooling approaches help manage wear and tear issues experienced with harder materials, such as titanium used in constructing aircraft fuselage. This approach extends functionality while reducing frequent maintenance costs.

Each strategy presents an innovative manner of addressing known issues in machine aerospace structures, thereby revolutionizing the associated processes effectively.

Impact on Aerostructures After Overcoming Barriers

The implementation of CNC machined structures into the aerospace industry significantly uplifts the functionality, durability, and safety attributes of aerostructures. Once these challenges are overcome, greater precision in manufacturing parts contributes to improved performance and robustness of aircraft structures. Machined components ensure less wear and tear due to their superior quality rendering them safer for extended use. For example, rotor blades made using CNC machining have increased tolerance that endures intense pressures and results in minimized failure risks.

This ground-breaking technology also brings forth long-term benefits regarding efficiency and cost-saving. High-speed machining allows for rapid production hence reducing lead times. This fast-paced production coupled with lower chances of error reduces operational costs substantially. Moreover, the ability to recycle scrap material reduces wastage making it environmentally friendly. Therefore, by incorporating advanced CNC techniques, aerospace industries can reap advantages of enhanced quality and economy simultaneously, revolutionizing the future of aerostructures.

Summary and Future Possibilities of CNC Machines in Aerospace Structures

In previous sections, we have delved deep into the many dimensions of computer numerical control (CNC) machines in aerospace structures. The unique benefits that these powerful devices provide – such as precision, repeatability, and speed –- were explored in depth. We also examined how they break barriers by handling complex designs with ease, essential for crafting modern aerospace parts. Furthermore, we evaluated their pivotal role in reducing production time and manufacturing costs.

The future for CNC machined aerospace structures is incredibly promising. Continuous innovations and improvements are opening doors to even greater possibilities. The advent of 5-axis machines, for instance, has revolutionised the industry’s approach to intricate components. As technology evolves exponentially, it can be expected that newer functionalities will emerge and existing ones will become more refined.

- Enhanced automation could reduce human input further, thereby minimising errors and increasing productivity.

- Improvements in software designing and controlling tools would make operations much more intuitive and user-friendly.

- Lastly, leveraging AI and Machine Learning could enable predictive maintenance, saving valuable resources and downtime.

All these developments hint at an exciting journey ahead for both manufacturers and users of CNC machined aerospace structures. Rest assured, the advancements forthcoming will undoubtedly propel the sector towards unprecedented heights.

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Understanding CNC Machining: The Bead Blasting Process(cnc machining tools Valentina)

In the world of manufacturing, precision is paramount. One widely adopted method known for its precision is CNC machining. An integral subcomponent in the broader spectrum of CNC (Computer Numerical…