Challenges and Solutions in CNC Machining of Hardened Steels for Tool and Die Making

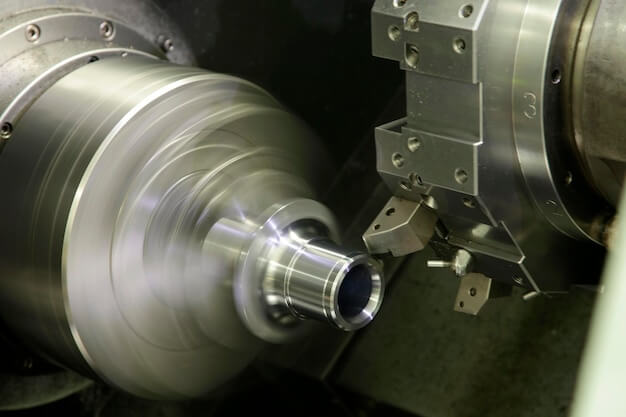

Introduction to CNC Machining and the Challenges of Hardened Steels CNC machining is a crucial process in tool and die making, heavily relied upon for its versatility and precision-driven manufacturing capacity. To put it simply, Computer Numerical Control (CNC) utilises computer-programmed software to drive factory machinery, thereby ensuring detailed accuracy in end products. The importance […]

Evaluating the Machinability of Nickel Alloys in CNC Processes

Introduction to Nickel Alloys and CNC Processes Nickel alloys, a class of materials renowned for their robustness and versatility, are used extensively in various sectors such as aerospace, chemical processing, nuclear systems etc. Offering superior resistance to corrosion, high-temperature degradation and stress, they represent an invaluable asset in crafting parts that require high reliability in […]

High-Speed Steel vs. Carbide in CNC Tooling: Which is Better for Your Manufacturing Needs?

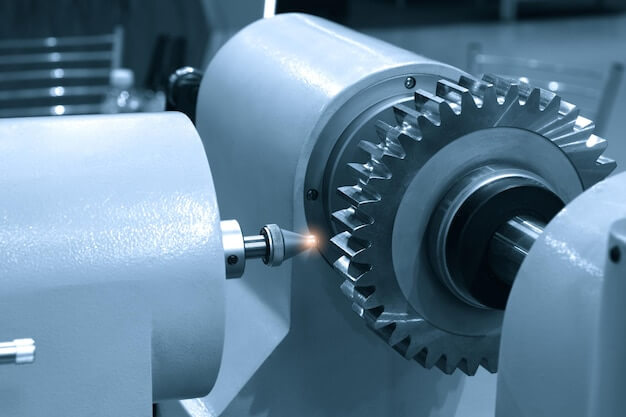

The Importance of Choosing the Right Material for CNC Tooling in Manufacturing In the manufacturing industry, choosing the right material for Computer Numerical Control (CNC) tooling is crucial. Every manufacturer aims at achieving efficiency, accuracy, and durability while keeping costs under control. Therefore, making an informed decision on whether to go for High-Speed Steel or […]

Advances in CNC Machining: Using Ultra-Hard Materials for Precision Parts

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise creation of parts by controlling machine tools via computer. This technology has revolutionized how products are made, from simple components to complex items, by offering unparalleled accuracy and repeatability. The evolution of materials used in CNC […]

CNC Machining for the Chemical Industry: Corrosion-Resistant Material Choices

Introduction to CNC Machining in the Chemical Industry CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, offering precision and efficiency by automating the control of machine tools with computer systems. Its significance is particularly pronounced in the chemical industry, where the demand for corrosion-resistant materials is high. This industry requires components […]

Enhancing CNC Machining with Smart Alloys: Shape Memory Metals vs. Traditional Alloys

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated shaping of materials. This technology relies heavily on the use of various materials, with traditional alloys and innovative smart alloys, such as shape memory metals, playing pivotal roles. Traditional alloys have been the backbone […]

Cobalt Chrome Alloys in Medical Implant Manufacturing: CNC Machining Considerations?

Introduction: Overview of Cobalt Chrome Alloys in Medical Implant Manufacturing Cobalt chrome alloys are extensively involved in the production of medical device implants due to their superior characteristics such as high hardness, wear resistance and excellent biocompatibility. This alloy constitutes primarily of cobalt and chromium, with smaller amounts of elements such as molybdenum which offer […]

Nickel vs. Cobalt Alloys in High-Temperature CNC Machining: A Detailed Analysis?

Nickel and Cobalt Alloys in High-Temperature CNC Machining Both Nickel and Cobalt alloys play an essential role in high-temperature CNC machining. These metal alloys are popular choices due to their outstanding thermal stability, hardness, wear resistance, and superb tensile strength at high temperatures. Nickel alloys have exceptional corrosion resistance, making them ideal for extreme environments […]

The Role of Bronze Alloys in Modern CNC Machining: Durability vs. Machinability?

Introduction to CNC Machining and Bronze Alloys CNC machining, or Computer Numerical Control machining, is a manufacturing process that uses pre-programmed computer software to guide the movements of factory machinery and tools. This technology enables precise control in terms of speed, position, coordination, and feed rate which is crucial for high-quality manufacturing outcomes. Components manufactured […]

Machining Hardened vs. Pre-Hardened Steel: What You Need to Know

Introduction to Machining Hardened and Pre-Hardened Steel Machining hardened steel refers to the process where solid blocks of hardened steel are cut into particular shapes using specialized machining tools. It’s a method regularly applied in various manufacturing industries due its precise results. The steel hardening process involves heating the metal to high temperatures, then rapidly […]

The Role of CNC Machining in Custom Fabrication of Industrial Machinery Components

The Role of CNC Machining in Custom Fabrication CNC (Computer Numerical Control) machining stands at the intersection of technology and manufacturing, providing a precision-driven approach to custom fabrication. Vital for producing industrial machinery components, CNC machining enhances output quality while reducing production time. This process offers advanced computer-aided design and manufacturing techniques that enable the […]

Reducing Manufacturing Costs with Multi-Material CNC Machining Strategies

Introduction to Manufacturing Costs and CNC Machining Solutions Manufacturing costs significantly impact businesses, encompassing expenses related to materials, labor, and operations. These costs determine the final price of products, affecting competitiveness and profitability. CNC machining emerges as a strategic solution to reduce these costs. This advanced manufacturing technique offers precision and efficiency by automating the […]