Blog

How to Assess the Total Cost of Ownership for Brass CNC Machining Parts?

What is the Total Cost of Ownership (TCO) for Brass CNC Machining Parts? Understanding the Total Cost of Ownership (TCO) for brass CNC machining parts

Precision CNC Machining of Brass: Optimizing Techniques for Custom Metal Fabrication?

Precision CNC Machining of Brass: An Introduction In the realm of custom metal fabrication, precision CNC machining holds a cardinal position. This technological method entails

Custom Precision Machining of Stainless Steel for Medical Device Applications: What to Consider?

Custom Precision Machining of Stainless Steel for Medical Devices: A Crucial Component in Healthcare In the medical industry, custom precision machining plays a vital role

Online CNC Machining Services for Aluminum Parts: Cost-Effective Solutions for Low Volume Production?

Introduction to CNC Machining and Its Application in Manufacturing Aluminum Parts Computer Numerical Control (CNC) machining is a widely applied manufacturing process that uses pre-programmed

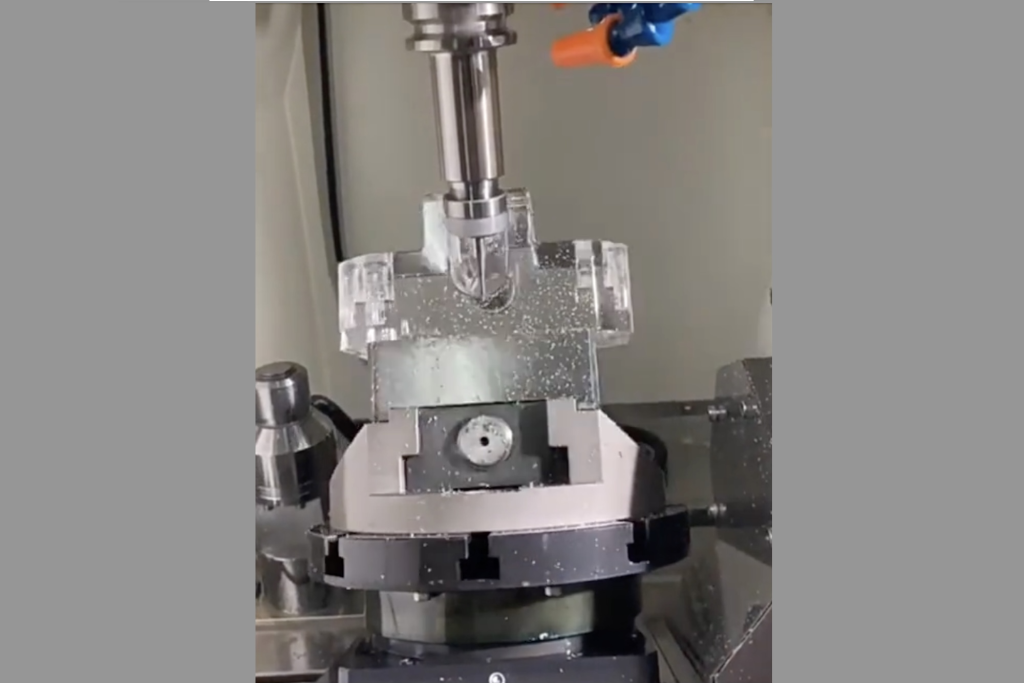

5 Axis CNC Machining of Titanium: Revolutionizing Aerospace Component Manufacturing?

5 Axis CNC Machining: Catalyzing Innovation in Aerospace Component Manufacturing In the realm of aerospace component manufacturing, 5 Axis CNC machining is a groundbreaking technology.

How Can Purchasing Managers Reduce Costs When Buying Brass CNC Machining Parts?

What Are the Primary Cost Drivers in Brass CNC Machining? Understanding the cost drivers is crucial for managing expenses effectively in the realm of CNC

How to Optimize Feed Rates and Speeds for CNC Machining Aluminum Parts?

Introduction to CNC Machining of Aluminum CNC machining of aluminum is a critical process in various industries, including aerospace, automotive, and consumer electronics, where precision

Graphite vs. Bronze in CNC Machining: Which Offers Better Precision and Durability?

Introduction: A Brief Explanation of CNC Machining and the Purpose of this Article CNC machining, standing for Computer Numerical Control machining, is a manufacturing process

Titanium vs. Inconel: Which is the Superior Material for High-Stress CNC Applications?

Introduction: CNC Applications and the Importance of Material Strength In high-stress tasks, such as those performed by Computer Numerical Control (CNC) machines, the strength of

Zirconium vs. Nickel Alloys: A CNC Machining Material Showdown for Corrosion Resistance?

Introduction to CNC Machining, Zirconium and Nickel Alloys Computer Numerical Control (CNC) machining is a sophisticated method used in modern manufacturing that involves the use

Ceramics vs. Hardened Steels: Who Wins for Wear Resistance in CNC Parts Manufacturing?

Ceramics vs. Hardened Steels in CNC Parts Manufacturing: A Brief Overview In the field of Computer Numerical Control (CNC) parts manufacturing, two materials often come

How to Minimize Tool Chatter in precision CNC machining of Aluminum Parts?

Introduction to Tool Chatter in CNC Machining of Aluminum Tool chatter in CNC machining significantly undermines the quality and precision of machined aluminum parts. This

What Are the Thermal Management Challenges in CNC Machining parts of Aluminum?

Introduction to Thermal Management in CNC Machining In the realm of CNC machining parts, thermal management is a pivotal aspect that significantly influences the quality,

What CNC Machining Techniques Are Best for Aluminum Parts in Food Automation?

Introduction to CNC Machining of Aluminum for Food Automation In the realm of food automation, precision and reliability are paramount. Aluminum parts play a critical

How to Overcome Corrosion Issues in Aluminum CNC Machined Parts for Food Machinery?

Introduction to Corrosion in Aluminum CNC Machined Parts Corrosion of aluminum parts in food machinery presents a significant challenge to manufacturers, as it not only

CNC Machining Parts: Tips for Writing Conflict-Free CNC Program Segments

CNC machining is all about precision and efficiency. One of the key aspects to get right is writing conflict-free program segments. A program segment tells

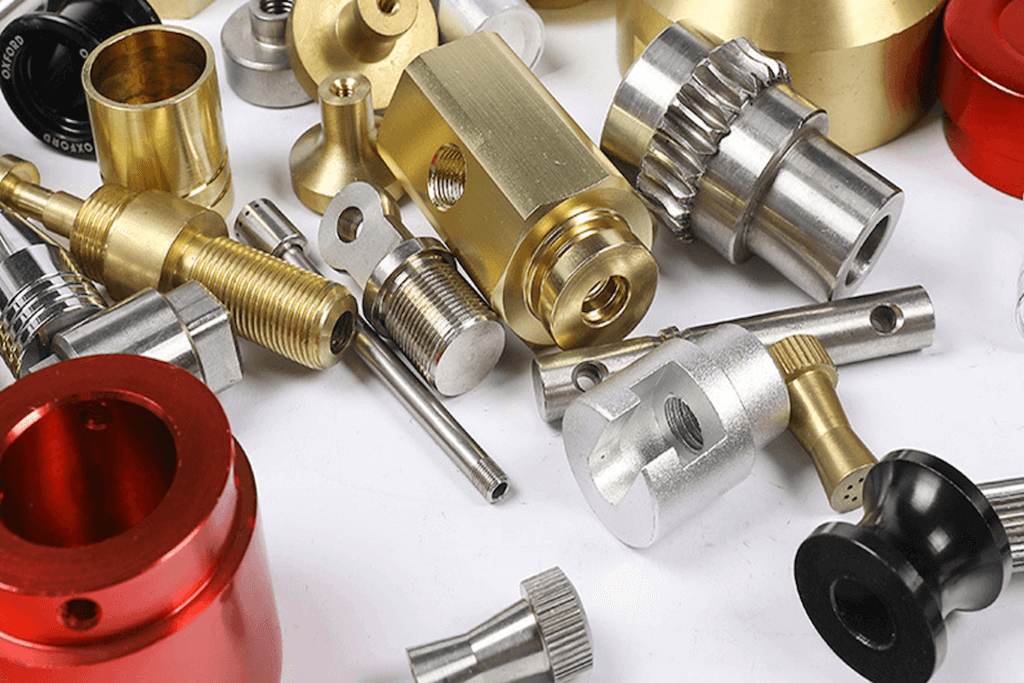

Common Materials and Processability of Mechanical Parts

Mechanical parts are indispensable components in various machines and equipment. To ensure these parts operate efficiently under different working conditions, it is essential to understand

Requirements for CNC Machining Parts

Preparation Work Complete the necessary preparation before machining, including process analysis, process route design, tool and fixture selection, and program compilation. online cnc machining service

CNC Machining Parts: In-Depth Analysis of Milling and Turning Program Segments

CNC machining is like the magic wand of modern manufacturing, where intricate designs are brought to life with pinpoint accuracy. At the core of this

Key Machine Functions in CNC Machining: Coolant, Spindle, Gear Range, and Accessories Analysis

One critical aspect of CNC programming is the use of M codes, which control various machine functions such as spindle rotation, coolant flow, gear range

Machine Functions in CNC Machining: Application and Optimization of M Codes

CNC machining has revolutionized the manufacturing industry by providing precise control over machine tools through programmed commands. A critical aspect of CNC programming is the

Application and Optimization Strategies of M Codes in CNC Machining Parts

CNC (Computer Numerical Control) machining is an essential part of modern manufacturing, bringing precision, efficiency, and consistency to the production process. Central to the operation

Detailed Explanation of Auxiliary Functions in CNC Machining Parts: Machine Operation and Program Control

CNC (Computer Numerical Control) machining is a cornerstone of modern manufacturing, enabling precise control over machining operations. A key component of CNC programming involves auxiliary

Precision CNC Machining: Optimizing G Code Grouping and Application

CNC (Computer Numerical Control) machining is a fascinating realm where precision meets innovation. At the core of this technology lies the effective use of G

G Code Preparation Functions and Optimization Strategies in CNC Machining Parts

CNC machining is a fascinating blend of precision, technology, and creativity. At its heart lies the use of G codes, which are vital for controlling

What maintenance and upkeep are required for a CNC drilling and milling machine?

A CNC drilling and milling machine is a versatile tool that can perform various processes such as drilling, milling, chamfering, and tapping. It operates through CAD/CAM software programming, CNC system execution, and motor control to perform complex procedures. Proper maintenance and upkeep are crucial to ensuring

Fundamentals of CNC Programming: Word Address Format and Program Blocks

CNC programming is an essential skill in modern manufacturing, allowing precise control over machining processes. One of the core elements of CNC programming is the

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- bits

- blasting

- bolts

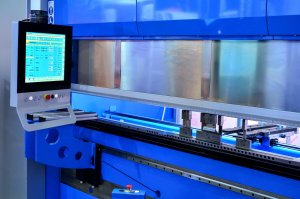

- brake

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- cnc turning

- coating

- composite

- concentricity

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

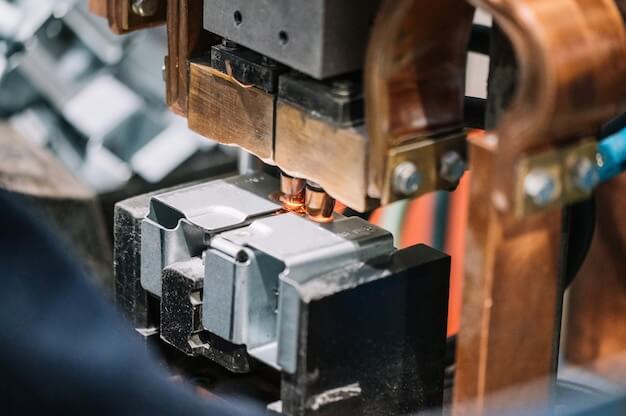

- EDM

- electroplating

- elongation

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- HDPE

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- NDT

- nipple

- nuts

- Nylon

- obj file

- PCB

- PEEK

- pewter

- Plastic

- pmma

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- spring steel

- Stainless Steel

- Steel

- stl

- stp

- Strain

- stress

- stud

- supplier

- surface finishes

- Teflon

- tempering

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- urethane

- VMCs

- washer

- Waspaloy

- watch

- yield

- Zinc

- Zirconium

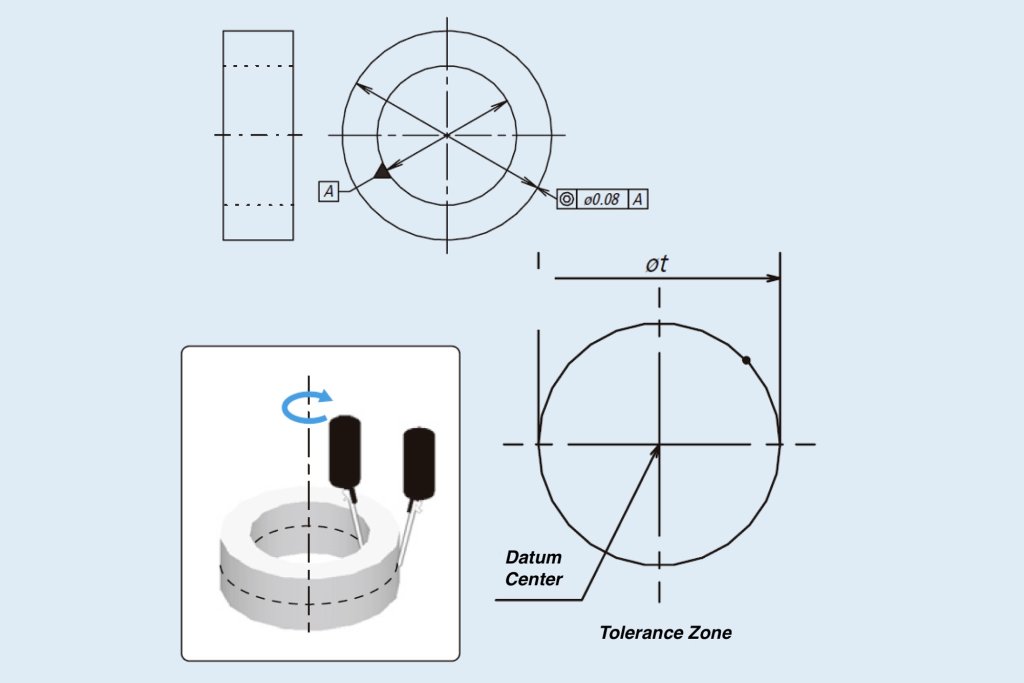

Master Concentricity: Practical Solutions for Precision Machining

Introduction to Concentricity in CNC Machining If you’ve ever worked with CNC machines, you’ve definitely come across the term “concentricity.” …

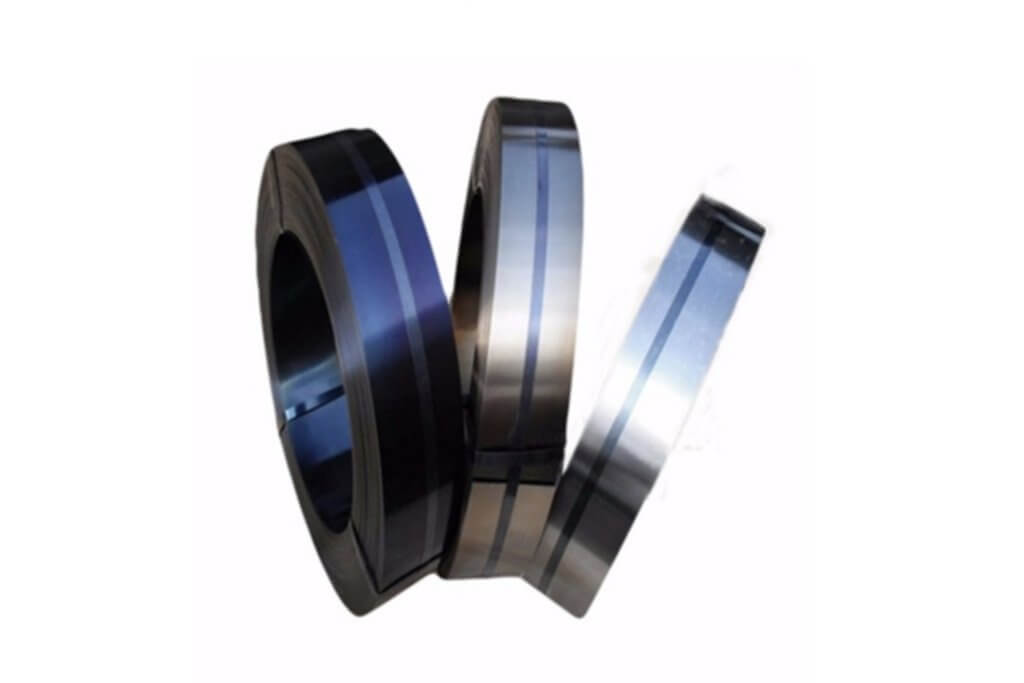

Can You Machine Spring Steel? A Complete Guide for Engineers and Machinists

What Is Spring Steel and Why Does It Matter? “Can you machine spring steel?”That was the exact question I asked …

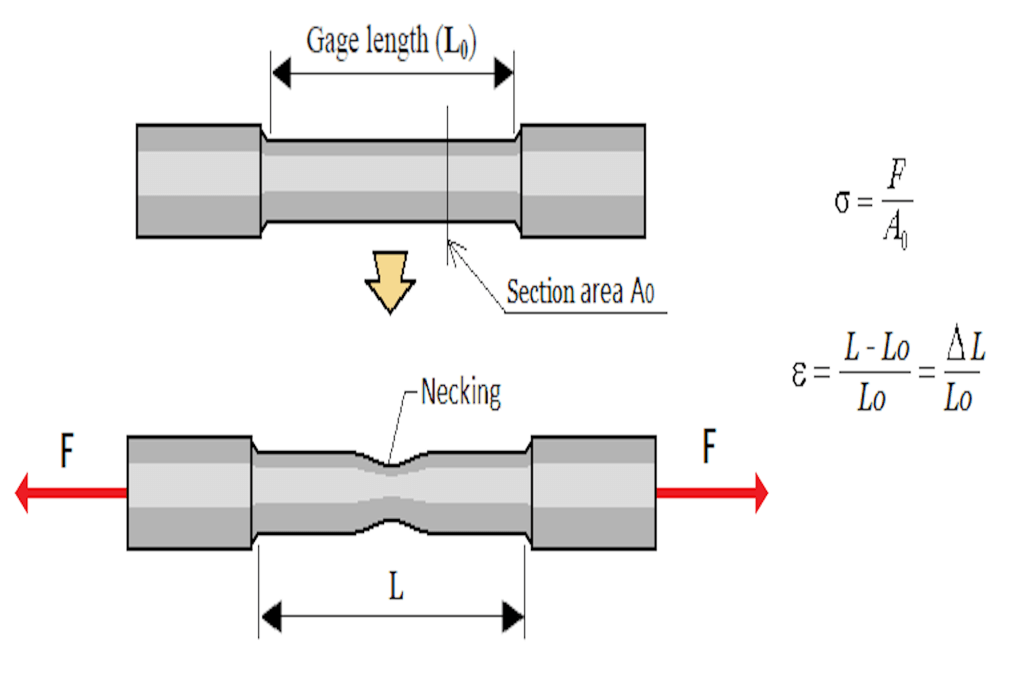

Tensile Test Insights for CNC-Machined Parts: Ensure Material Reliability Before Failure Happens

Introduction In my early days as a process engineer, I underestimated the importance of tensile test. I thought if the …

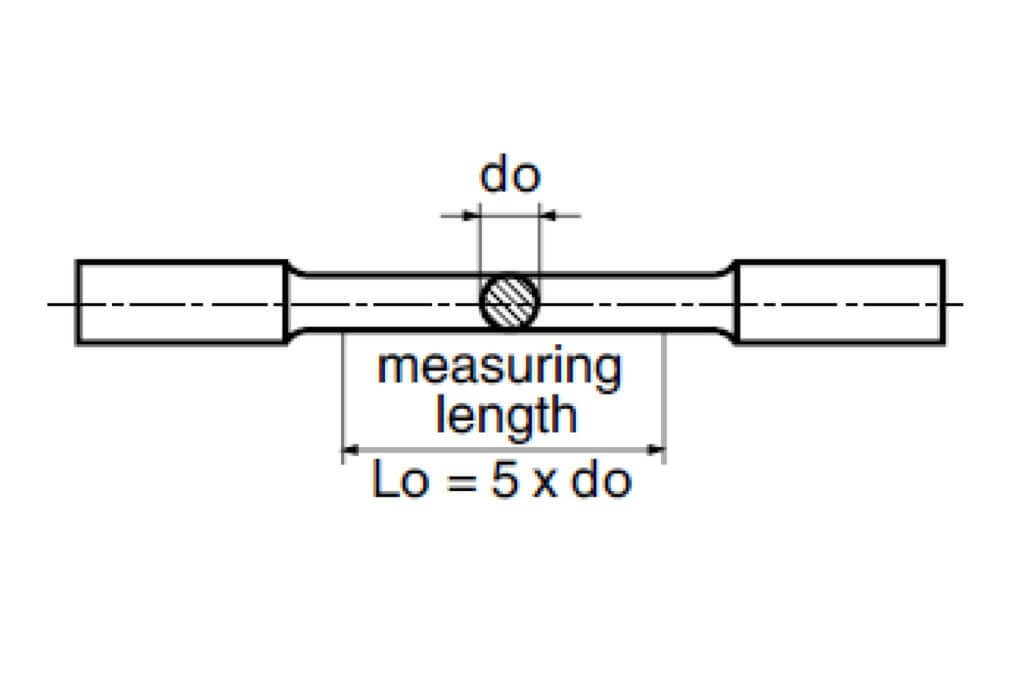

Elongation in Machining: What Engineers Must Know About Material Ductility

Introduction Elongation is one of those material properties that doesn’t always get the attention it deserves—until something breaks. I’ve seen …

Zinc Metal for Machining: Properties, Applications, Design Tips, and Supply Chain Insights

Introduction Zinc metal isn’t just another industrial material — it’s a workhorse that quietly powers a surprising number of industries. …

What Is an OBJ File? How to Open, Convert, and Use It in 3D or Manufacturing Projects

What Is an OBJ File? If you’ve worked with 3D models, especially in design or printing, you’ve probably come across …

How to Work with Chrome Metal in Machining: A Practical Guide

Chapter 1: What Is Chrome Metal? Before diving into CNC machining details, let’s clear up one thing: what exactly is chrome …

Properties of Metals Explained: The Complete Guide for Machinists to Select and Process Materials

Chapter 1: Introduction Why I Wrote This Guide on the Properties of Metals When I first started my career in …

Everything You Need to Know About PMMA Material for CNC Machining

Introduction When working in CNC machining, selecting the right material can make or break a project. One material I’ve come …

Ultimate Drill Bit Size Chart for CNC Machining: Find the Right Drill Every Time

Introduction When I started working with CNC machines, I quickly learned the importance of having a reliable drill bit size chart at …

Thinking of Using Satin Anodized Aluminum for CNC Parts

What Exactly Is Satin Anodized Aluminum, and Why Might You Choose It? I’ve worked with aluminum in a lot of …

Blind Rivet Installation Guide: CNC Drilling, Sizing, and Fixing Tips

Introduction When I first got into mechanical design, blind rivets were just something I saw used on factory floor panels. …