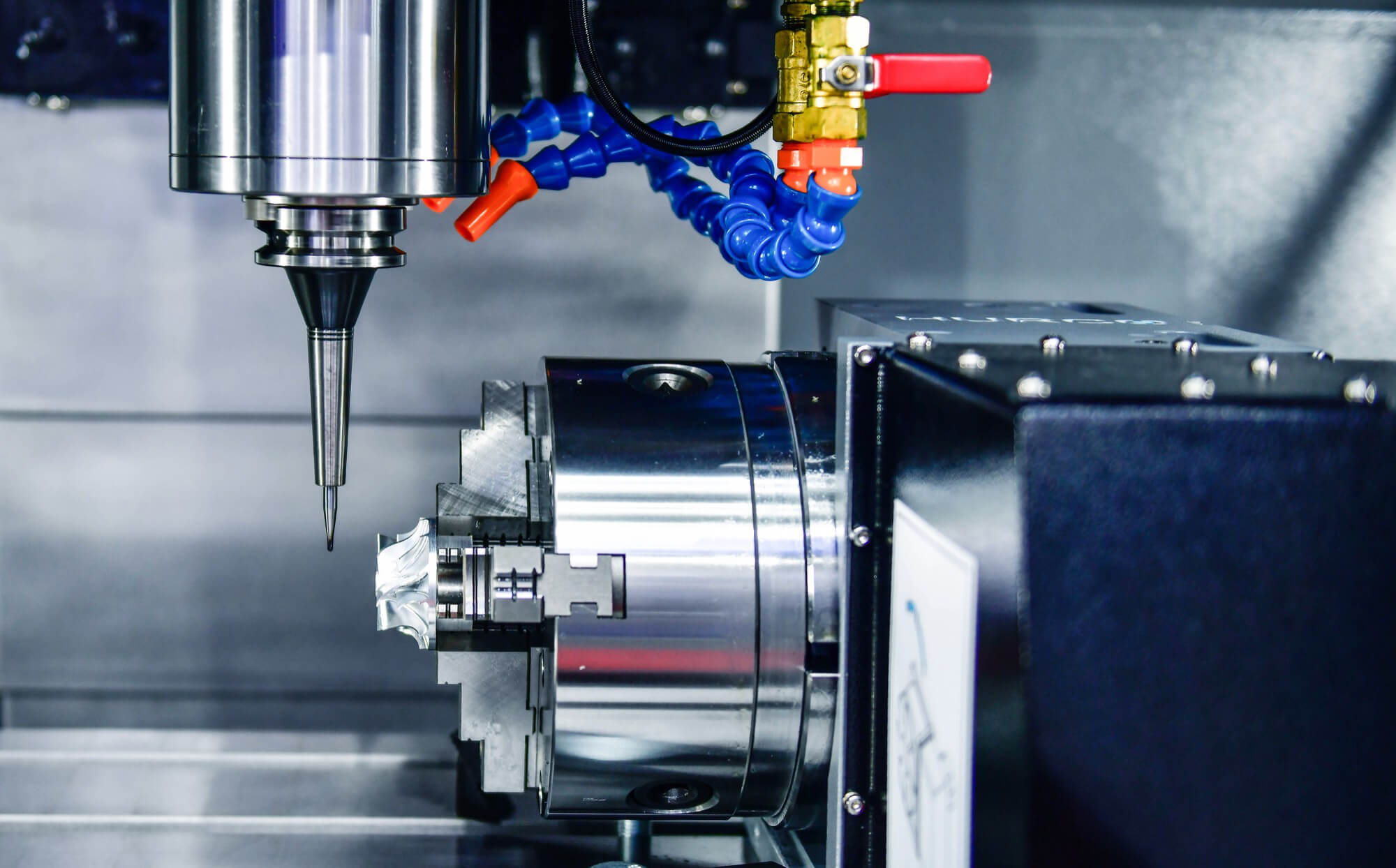

CNC (Computer Numerical Control) machining is a cornerstone of modern manufacturing, enabling precise control over machining operations. A key component of CNC programming involves auxiliary functions, often referred to as machine functions or M codes. These functions play a crucial role in both machine operation and program control, ensuring smooth and efficient machining processes. Let’s explore the intricacies of auxiliary functions in CNC machining parts, focusing on their application in machine operation and program control.

Understanding Auxiliary Functions (M Codes)

Auxiliary functions, or M codes, are essential instructions in CNC programs that manage various machine operations and program flow. These codes help activate specific machine functions or control the execution of the program, making them indispensable for complete and operational CNC programs.

Machine Operation Functions

Auxiliary functions related to machine operations control several critical aspects of CNC machines, such as spindle rotation, gear range changes, automatic tool changes, coolant operations, and movement of tailstocks or quills. These functions ensure that the CNC machine performs its tasks accurately and efficiently.

Common Machine Operation M Codes:

- M03: Spindle on (clockwise rotation)

- M04: Spindle on (counter-clockwise rotation)

- M05: Spindle stop

- M06: Tool change

- M08: Coolant on

- M09: Coolant off

- M19: Spindle orientation

These M codes are fundamental to the operation of CNC machines, enabling the execution of various machining tasks. For example, M03 starts the spindle in a clockwise direction, essential for most milling operations, while M06 automates tool changes, enhancing efficiency and precision.

Program Control Functions

Apart from machine operations, auxiliary functions also control the flow of the CNC program. These functions are crucial for managing interruptions in program execution, calling subprograms, or managing workpiece setups.

Common Program Control M Codes:

- M00: Program stop

- M01: Optional stop

- M30: Program end and rewind

- M98: Call subprogram

- M99: Return from subprogram

These M codes ensure that the CNC program runs smoothly, allowing for necessary pauses, subprogram calls, and orderly completion of machining tasks. For instance, M00 halts the program until the operator intervenes, useful during setups or inspections.

Practical Applications of Auxiliary Functions

To understand how these auxiliary functions work in practice, let’s look at a typical CNC machining program that utilizes both machine operation and program control functions.

Sample Program:

O1000 (Main Program)

N10 G90 G21 (Absolute positioning, metric units)

N20 T01 M06 (Select tool 1, change tool)

N30 S1500 M03 (Spindle speed at 1500 RPM, start spindle)

N40 G00 X0 Y0 Z5 (Rapid move to start position above part)

N50 G01 Z-5 F100 (Feed to cutting depth)

N60 G01 X50 (Linear move to X50)

N70 G02 X75 Y25 I25 J0 (Clockwise arc)

N80 G01 Y50 (Linear move to Y50)

N90 G03 X50 Y75 I-25 J0 (Counter-clockwise arc)

N100 G00 Z5 (Retract tool)

N110 M30 (End of program)In this program, various auxiliary functions are employed to manage both the machine’s operations and the program’s flow. The M codes used include M06 for tool changes, M03 for starting the spindle, and M30 for ending the program.

Optimization Strategies for Auxiliary Functions

Effective use of auxiliary functions can significantly enhance the efficiency and precision of CNC machining. Here are some strategies for optimizing these functions:

- Efficient Tool Management:

Proper use of M06 (tool change) and related functions can minimize downtime and improve tool usage. Organizing tool changes logically within the program reduces unnecessary movements and enhances cycle time. - Smart Coolant Management:

Utilizing M08 (coolant on) and M09 (coolant off) effectively can improve tool life and machining quality. Coolant should be turned on just before cutting and off after the cutting process is complete to avoid unnecessary coolant usage. - Optimized Program Stops:

Using M00 and M01 judiciously can help manage workflow without unnecessary interruptions. M00 can be used for critical inspection points, while M01 provides optional stops that operators can bypass if continuous operation is preferred. - Subprogram Utilization:

M98 (call subprogram) and M99 (return from subprogram) allow for modular programming, reducing code redundancy and simplifying complex programs. Subprograms can be reused across different main programs, saving time and effort.

Example of Subprogram Utilization:

O2000 (Drilling Subprogram)

N10 G81 R1 Z-10 F200 (Drill cycle)

N20 X10 Y10 (Drill hole 1)

N30 X20 Y20 (Drill hole 2)

N40 G80 (End drill cycle)

N50 M99 (Return to main program)In the main program:

N90 M98 P2000 (Call subprogram O2000)This approach not only reduces the length of the main program but also makes it easier to read and debug.

Auxiliary functions are the backbone of effective CNC programming, bridging the gap between machine operation and program control. By mastering these functions and applying optimization strategies, machinists can significantly enhance the efficiency, precision, and overall quality of their CNC machining processes. Whether you’re new to CNC machining or a seasoned professional, understanding and leveraging auxiliary functions will undoubtedly lead to better machining outcomes.

Other Articles You Might Enjoy

- Precision Metalwork: Lightweight CNC Machining and Chrome Removal( cnc machine tools Norman)

CNC machining, a dominant force in the world of manufacturing, is intricately involved with creating complex parts out of lightweight metal, as well as removing chrome from metal components. This…

- Plastic vs. Metal CNC Machining: A Detailed Comparison?

CNC Machining: An Essential Process Across Industries Computer Numerical Control (CNC) machining is a digital manufacturing technology that makes use of pre-programmed computer software to dictate the movement of various…

- Revolutionizing CNC Machining for the Future of Smart Wearables

Introduction: CNC Machining and Smart Wearables CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to operate and manipulate machine tools, converting raw materials into finished…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- The Art of Bead Blasting in CNC Machining(cnc laser cutting machine Cyril)

Bead blasting is a finishing process frequently used in many industries, including the world of Computer Numerical Control (CNC) machining. It involves forcefully propelling a stream of abrasive bead material…

- PEEK vs. PEI (Ultem) in CNC Machining: A High-Performance Plastics Showdown

Introduction: PEEK vs. PEI (Ultem) in CNC Machining When it comes to high-performance plastics for Computer Numerical Control (CNC) machining, two names often arise - Polyether Ether Ketone (PEEK) and…