According to a report published on 30 January 2023, CNC milling services requirement will cross US$ 110,203 millions by 2033. It is due to the increasing demand in the food, automotive, and machining industries where the user is seeking more advanced customized milling machined parts online.

According to the CNC milling Wikipedia page, after covid 19 the demand for low-price CNC services is rising globally. Similarly, the companies are looking forward to the production of metal milled parts which should meet their contemporary requirements. Therefore, it is important to understand:

- The basic principles of milling machine

- Types of CNC milling machine

- What is the process of new milling machines?

Before you start learning various types and processes of milling machining, the first step is to learn the simple basics of CNC machines and understand how they work. If you are a beginner or searching for a CNC operator job in 2023 and want to improve your machining knowledge, this article will walk you through some of the basic concepts.

How to understand the definition of CNC Milling?

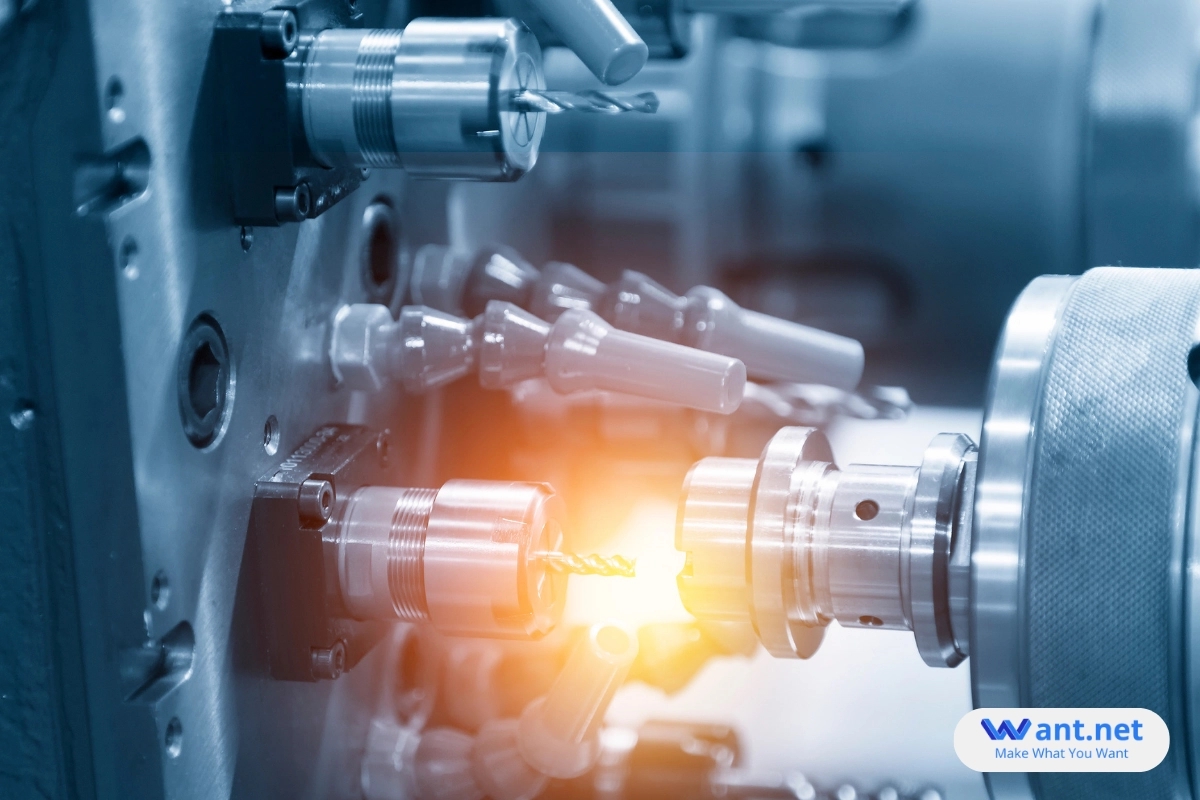

Milling is a machining process that uses computer control machines to manufacture custom CNC milled parts. In addition, this includes rotating multi-point tools to remove unwanted materials from your milling part.

After that, you get a fully customized part in perfect condition. It is important to learn that modern machining companies follow customers’ designs to mill any part.

Subsequently, the price of a custom milling part fairly depends on the complexity of the design. In addition, the quantity of CNC milling parts also affects the cost of machining parts.

At Want.net, getting an online quote for custom CNC parts for online orders is extremely easy. The process for getting a quotation for CNC milling parts in China is as follows:

- Write Name in Given Section

- Write Email

- Country for Shipping

- Select the type of service you require (CNC machining, injection molding, sheet metal fabrication, 3D printing)

- Write your requirements

- Choose the file button to send your product design

- Press Send Button

What kind of materials can be processed in CNC milling?

The CNC milling process is ideal to use in:

To obtain a perfect design, CNC machining removes excessive material from the part.

Types of CNC Milling Machines For Metal

CNC milling is quite different from outdated mechanical units, especially in terms of automation and execution of complex custom parts. The control program embedded in the machine plays a crucial factor for:

- Moving the spindle head

- Rotating the table

- Other functions of the equipment.

Modern CNC milling machines work perfectly to create a working shape according to the given design. Usually, in this process, the following points are important to consider:

- Material Selection

- The parameters of the cutter

- The path of its movement and other aspects necessary for milling

What are the three major tasks of a CNC milling machine operator?

- Start the Milling machine to produce custom parts

- Fix the material on the work surface

- Adjust the processing speed and power modes through the control panel and monitor the progress of the operation.

Advantages of a CNC Milling Machining

Automatic milling machines have a lot of advantages over old-style equipment, so most large and small companies are trying to update their machining center and purchase modern high-tech models. In a long list of pluses, factors such as:

- Highly Precision Custom Parts. The deviation of the cutter from the specified parameters varies in the range of 0.02-0.07 mm, which totally outnumbers conventional machine tools where traditional machining has higher chances of error

- Efficiency increase reaches 50%;

- Manufacturing of mass machining milled parts

- Faster turnout for small and large batches

- Capable of manufacturing customized machined parts with excellent speed

- Low-Cost Manufacturing

What is the scope of automatic CNC milling machining?

According to a report on CNC milling scope published in Fortune Business Insights, the rising demand of mass custom machined parts will expand the CNC machining industry to $16.01 billion by 2026. The milling cutter belongs to the category of universal devices suitable for processing a large number of materials, so you can find such machines in a variety of areas:

- Metalworking

- Woodworking

- Medical Industry

- Jewelry industry

- Modeling and more.

Types of CNC Milling Machines

Program-controlled milling machines can be classified according to several criteria:

Processing material

- Metalworking equipment designed for cutting, drilling, threading, etc. of metals and their alloys. It features a reinforced structure that can withstand heavy loads and a powerful engine.

- Woodworking machines function as the full range of milling work on wood and all other non-metallic materials. With a great visual resemblance to a metal router, they are equipped with a lighter bed.

What are the major functions of CNC Milling Machines?

- Milling and engraving – for engraving on any materials, from metal to leather.

- Milling and turning – combined devices that combine the equipment of the turning and milling groups. The special design of the milling head allows you to fix in it not only various types of milling cutters, but also turning cutters, so on such machines you can perform drilling, reaming, cutting operations, create chamfers, trim the material, and also perform the processing of bodies of revolution.

- Milling and drilling – they are compact in size and can perform both milling work and operations for threading, reaming, reaming holes, etc.

- Vertical – with the top placement of the spindle head, which can move along the console in the vertical and horizontal plane? The working area is located under the cutter.

- Horizontal – with the lateral placement of the cutting tool. The spindle assembly is static, processing occurs by moving the desktop relative to the cutter.

- Universal – machines that allow you to perform drilling, turning, and milling for custom parts with vertically and horizontally positioned workpieces. Most models are equipped with a turntable.

- Widely versatile – multifunctional equipment of CNC milling allows not only to carry out all types of operations possible for machines of this kind but also to process the workpiece along several axes simultaneously (maximum five axes).

Dimensions of CNC Milling For Custom Machined Parts

Mini Milling Cutters

With a working field of 400 × 400 mm, such models are used in the handmade sphere and, in addition to small dimensions, also have minimal power and limited functionality;

Table routers

The size of the processing zone is 600 × 900 mm. Fit on desktop. They can interact with any materials and perform all types of work, but due to their low power they work rather slowly, therefore they are suitable only for the manufacture of small-scale products.

They are purchased mainly for personal use or small-scale production.

Medium format machines

The table dimensions are 1300 × 1300 or 1300 × 2500 mm. Professional equipment with a powerful spindle, suitable for any job. Used in all small and medium enterprises.

Large-sized equipment

These are powerful machines with a large working field (up to 2000 × 3000 mm) and high productivity for work with large volumes of products. It is used in large metal and woodworking enterprises.

How does CNC milling work? Explanation with Examples

The cnc milling process starts by creating a 3D CAD design of the part. Therefore, you send the project to a compatible file format, which will be converted according to the NC program. The program will determine the actions of the machine and how the tools will move around the workpiece.

Before any operation, the user must fix the workpiece on the surface of the machine. When the device is ready, the user will run the program through the machine interface. As a result, the machine will start the milling process to make precision custom metal parts.

When you start the CNC milling process, the machine will prompt the cutting tools to rotate at high speed. In addition, the machine will slowly feed the workpiece into the rotating mechanism.

The principle of operation of a CNC machine is very different from a manual process. Here it feeds the moving parts as the cutting tool rotates.

We usually use milling as the final process. It works by adding beautiful features that make the final product functional and attractive. Some of the features achieved with milling are threads, slots, and holes.

You can also use the milling process to shape a specific material from start to finish. To give the desired shape, you need to remove objects. The tool will cut small chips to give them an approximate shape or shape.

As the workpiece is milled, the machine gently and accurately adds features that reflect the exact specifications.

CNC Milling Operations: 8 Unique Processes of Milled Parts

If you need high-precision custom metal parts, you can use CNC milling on parts with high tolerances. The uniqueness of the CNC router, it has several useful applications to produce various designs. Let’s discuss some of the most common milling operations.

a) Face milling

This is a type of operation where end mills are used in the process. Milling cutters have teeth both on the end of the tool and on the periphery. The role of the peripheral teeth is to cut while the facial teeth are used in finishing.

In addition, you can use face milling to create contours and flat surfaces on finished parts. Interestingly, you can use this method to get a better finish. In addition, this process is used on both horizontal and vertical milling machines.

b) Conventional milling

This is also called surface CNC milling. This process will involve simple cutters with teeth on the periphery so that the cutting operation can be performed. The result will be based on the following specifications:

- Cutting depth

- Workpiece size

If you use narrow cutters, you will get deeper cuts. You can use more full cutters when cutting larger surfaces. If you are going to remove a large amount of material, the operator will use a cutter with large teeth.

c) Corner milling

This process uses single-angle cutters. The angle will reflect the specific CNC parts design you wish to process. Later, he will create corner features such as grooves, teeth, and chamfers.

Corner milling can be used to create a dovetail.

d) Form milling

Form milling uses uneven surfaces, contours, and contours. It used highly curved surfaces. This process uses fly cutters that are suitable for certain applications such as concave and convex cutters.

e) Band milling

Group milling is a process that uses two or more cutters on one specific machine tool holder. They can vary in shape, size, and shape. Surprisingly, each cutter can perform different or identical cutting operations at the same time. It can create intricate designs in a short amount of time.

f) Straddle milling

The XY milling process involves double cutters on a specific machine tool holder. The cutters are on both sides of the workpiece.

g) Gear cutter

In the manufacture of gear teeth, gear cutters are used. You can get them in different shapes and sizes. You can also use a specialized lathe to perfect this process.

h) Profile milling

To facilitate the process, profile milling equipment will be used. These cutting tools may be perpendicular or parallel to the surface of the workpiece.

CNC Router Components for Custom Machined Parts

The CNC machine separates the necessary parts. Like these:

- Machine interface: The operator will use these components when starting, loading, and executing the CNC machine program.

- Knee: This is the component that provides support for the desktop and saddle. You can adjust this component in the Z-axis.

- Column: It plays a critical role in providing support and structure to machine components.

- Desktop: This is the component that sits on top of the saddle. You can adjust it both vertically and horizontally.

Important Rules Processing Materials in CNC Milling

The CNC router uses different materials to achieve a certain process. This will give the final product a spectacular look. Here is a list of materials that you can use for milling.

Also Read: 2023 Best CNC Machining Company From China: Machined Parts Guide for Beginners

- Ceramic Granular Sand for Hydraulic Fracturing

- Elastomers

- Glass

- composites

- plastics

- Metallurgy

When performing a CNC milling process, you must consider the following specific material properties:

- Shear and Tensile Strength

- Hardness

- Heat resistance

- Chemical structures

You should choose materials wisely that suit your needs.

Conclusion

Customers are always looking for unique custom metal parts to meet modern requirements. It was impossible to manufacture shapes on complex geometries without a reliable CNC machining company.

Also, when milling, you can use several types of materials that best meet your part’s design. The uniqueness of CNC milling machines allows them to perform various manufacturing processes.

Try Low-cost CNC Milling with want.net by Sending us Quotation Online

Want.net has comprehensive solutions for CNC machining, milling, and turning metal parts. With excellent expertise in high-quality rapid prototyping and small batch production, we offer high-volume production. We offer state-of-the-art surface treatment finish services in China.

Related Posts

- The Advantages of Using Molybdenum in CNC Machining Applications

CNC Machining Applications and the Role of Molybdenum Computer Numerical Control (CNC) machining is a revolutionary process transforming raw materials into intricate components. This cutting-edge approach automates control of machining…

- Decoding the Process of CNC Bead Blasting(milling machining Ted)

Bead blasting is an essential subset and technique used in Computer Numerical Control (CNC) machining. It involves the process of removing surface deposits by applying fine glass beads under high…

- Aluminum CNC Machining Service for Custom Parts

Aluminum CNC machining stands at the forefront of modern manufacturing, epitomizing precision, versatility, and efficiency. With its widespread applications across industries ranging from aerospace to automotive and beyond, aluminum CNC…