For clients who are new in the CNC prototyping industry, finding a reliable company that can meet their demands can be a challenging task. However, understanding what to look for and how to navigate the process can save time and ensure the production of high-quality prototypes. In some cases, a company may choose to manufacture specific components in-house, while other times they may seek the services of a prototyping specialist. The decision ultimately depends on the manufacturer’s requirements and the available resources to accomplish the task.

In many instances, collaborating with a third-party prototyping company offers significant advantages in terms of cost and quality. However, building a seamless partnership with the prototyping manufacturer is the key to success. Once this connection is established, the prototyping experts can deliver prototypes that align with the client’s specific needs and requirements. However, before proceeding, it is essential to understand the different types of prototyping.

Classes Of Prototypes

There are two primary classes of prototypes in the CNC prototyping industry:

1. Low-Fidelity Prototypes

A low-fidelity prototype is designed to incorporate some elements of the final product. These prototypes focus mainly on the look and feel of the end product rather than its functionality. By creating low-fidelity prototypes, manufacturers can visually demonstrate to clients how the product will appear in its final production phase. These prototypes are relatively quick to manufacture and provide greater flexibility for scalability during the product development cycle. Manufacturers can easily add or remove features to fine-tune the product design.

2. High-Fidelity Prototypes

High-fidelity prototypes involve a more comprehensive design that closely resembles the end product both aesthetically and functionally. These prototypes encompass all aspects of the user interface (UI) and user experience (UX) of the final part. High-fidelity prototyping becomes crucial during the final stages of the product development cycle, as it allows for testing and evaluation of interactive elements and visuals. Although high-fidelity prototypes are more expensive and less adjustable than their low-fidelity counterparts, they provide clients with a detailed representation of the final product, enabling valuable feedback and validation.

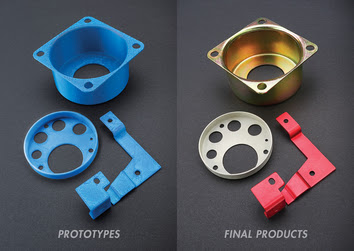

It is important to note that prototypes serve various functions, but they are not intended for commercial use and do not replace the final products. Prototypes are commonly used for demonstrations, testing and evaluation, business pitches, patenting, market research, production run-throughs, and other activities.

Functionality Of Prototypes

Prototyping should not be confused with production. While prototypes may be incorporated during the production cycle to showcase the potential aesthetics and functionality of a product, they do not serve as final commercial products. Prototypes allow companies to gather feedback, refine designs, and validate concepts before proceeding with full-scale production.

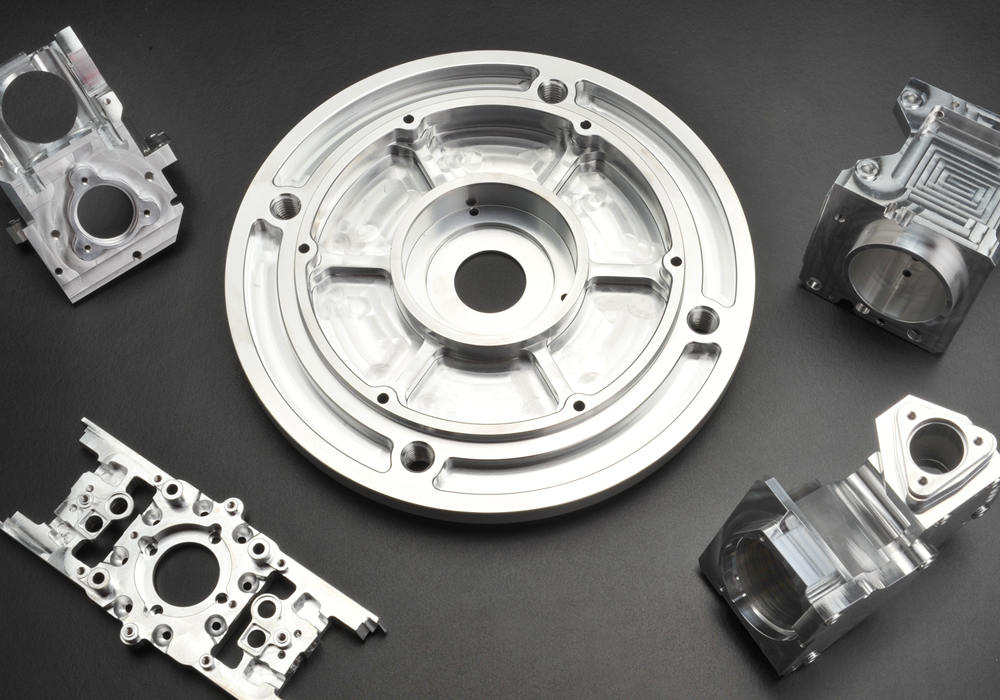

Due to their functionality, prototyping companies typically manufacture these one-off components in small quantities, usually less than 100 units. As a result, they do not require large-scale production facilities for fabricating such parts. In the CNC prototyping industry, CNC machining technology plays a significant role by providing the capability to build CNC-machined prototypes in batches within a short timeframe. This manufacturing process offers end-users the flexibility to carry out production from concept to final production. CNC machining companies assist customers in improving product design, enabling them to save resources and create the ideal product for mass consumption.

Merits Of CNC Rapid Prototyping

CNC rapid prototyping offers several advantages when it comes to production. One of the key benefits is speed. CNC machines can finish prototypes in a relatively short period compared to human labor, especially when dealing with large quantities. This accelerated process eliminates human errors during fabrication and ensures precise cutting of prototypes.

Another advantage is the accuracy achieved through CNC prototyping. Manufacturers can seamlessly incorporate prototyping components into the production linewithout incurring excessive costs. The accuracy and efficiency of CNC prototyping also help in minimizing material wastage, leading to cost savings.

Moreover, CNC prototyping can be particularly beneficial in metal fabrication prototyping, which often involves complex and labor-intensive procedures such as stamping, welding, extrusion, folding, spinning, bending, cutting, and finishing. By implementing CNC prototyping, manufacturers can automate the metal prototyping process, reducing the need for extensive manual labor and saving valuable resources. Machinists can program CNC machines to cut solid parts precisely according to the provided blueprints, ensuring accurate metal fabrication techniques. The computer reads the programmed instructions and guides the machine to cut, spin, bend, and fold the metal parts into the desired shape and form before advancing to other production processes. Consequently, many manufacturing companies favor CNC prototyping technology over other methods due to its efficiency and reliability.

How To Search For An Ideal CNC Prototyping Company

With numerous manufacturers specializing in CNC prototyping, finding the right company can be a daunting task for clients. However, by considering the following factors, clients can increase their chances of finding a reliable CNC shop:

- Delivery Speed: In the CNC prototyping industry, timely product delivery is crucial to meet market demands. An ideal CNC company should have a track record of designing and delivering prototypes promptly, ensuring that clients can meet their deadlines.

- Quality Control: While speed is important, ensuring high-quality prototypes is equally vital. A reputable CNC manufacturer must prioritize quality control and adhere to industrial standards. Providing documentation and certification guarantees the quality and reliability of their products.

- Customer Service: Excellent customer service is crucial for establishing long-term partnerships. A reliable CNC shop should not only handle customer requests, inquiries, and complaints promptly but also provide expert advice and support. They should be able to accommodate unusual requests and maintain effective communication throughout the prototyping process.

By considering these factors and conducting thorough research, clients can find an ideal CNC prototyping company that meets their specific requirements.

The A – Z Of Ordering A Prototype From A CNC Shop

For clients new to the prototyping process, ordering prototypes from a third-party CNC prototyping company may seem overwhelming. However, the process can be simplified by following these steps:

Request for Quotation (RFQ)

The client submits an RFQ to the prototyping manufacturer, detailing their specific requirements. This document serves as a formal request for a cost estimate and outlines the project’s scope.

Design File Submission

Along with the RFQ, the client provides a digital design file containing the blueprint or specifications of the prototype. The design file can be in formats like stereolithography (STL) or standard for the exchange product model data (STEP). This file helps the company visualize the client’s desired product accurately.

Non-Disclosure Agreement (NDA)

If the client agrees to proceed with the prototyping company, a non-disclosure agreement is signed. This agreement ensures the confidentiality of the client’s blueprints and prevents them from being shared or sold to other parties.

Prototype Manufacturing

Once the NDA is in place, the CNC shop starts manufacturing the prototypes based on the client’s requirements and design specifications. They employ their expertise and CNC machining technology to bring the prototype to life.

Constant Collaboration

Throughout the prototyping process, the client and the CNC manufacturer engage in constant communication and collaboration. The client receives regular updates on the design progress and can provide feedback for refinement.

Adjustments and Improvements

If the client is dissatisfied with any aspect of the prototype, the CNC company can make necessary adjustments to meet their satisfaction. The client’s input is crucial in ensuring the final prototype meets their expectations.

Manufacturing Completion

Once the prototype meets the client’s requirements and receives their approval, the CNC shop completes the manufacturing process. They may manufacture the prototype entirely in-house or outsource certain design elements, depending on the project’s complexity and uniqueness.

Review and Evaluation

Before finalizing the prototype, the client thoroughly reviews the design, functionality, and overall quality. If any further adjustments or improvements are necessary, they can be addressed at this stage.

Delivery and Feedback

Once the prototype is ready, the CNC shop delivers it to the client. The client evaluates the prototype and provides feedback, which is crucial for refining the design and making any necessary modifications.

Continued Partnership

After successful prototype delivery, clients may choose to continue working with the CNC prototyping company for future projects. Establishing a strong and ongoing partnership ensures seamless collaboration and consistent quality in future endeavors.

By following these steps, clients can navigate the process of ordering prototypes from a CNC shop effectively, ensuring the development of high-quality prototypes that meet their specific needs.

In conclusion, the role of a prototyping company in the CNC prototyping industry is pivotal in delivering high-quality prototypes. By understanding the different classes of prototypes, the functionality of prototyping, and the benefits of CNC rapid prototyping, clients can make informed decisions when choosing a CNC shop. Considering factors such as delivery speed, quality control, and customer service helps in identifying an ideal CNC prototyping company. The process of ordering prototypes involves submitting an RFQ, providing a design file, signing an NDA, collaborating with the manufacturer throughout the prototyping process, and evaluating the final prototype. By following these guidelines, clients can streamline the prototyping journey and achieve successful outcomes in their product development endeavors.

Recommended Reads:

- Simplifying Complex Workpieces with CNC Machining Technology

- The Application of Coordinate Measuring Machines (CMM) in Modern Machine Shops

- How To Adapt Fixtures and Jigs for Intelligent Manufacturing

- How to Reduce the Cost of CNC Prototyping

- The Era of 5G: Transforming the World through Precision Machining

- The Art of CNC Precision Machining: Crafting High-Quality Parts

- Increase Your CNC Production Efficiency with a Robotic Arm

Other Articles You Might Enjoy

- Exploring Bead Blasting in CNC Machining(3d prototyping James)

Bead blasting is a surface treatment process extensively used within the field of Computer Numerical Control (CNC) machining, which has revolutionized manufacturing industries. This method comes under focus due to…

- Jewelry Prototyping with CNC Machining

Jewelry manufacturing, one of the world's oldest trades, continues to evolve with advancements in technology. While traditional methods have served the industry well, CNC Rapid Prototyping is emerging as a…

- Precision CNC Machining Manufacturer for High-Quality Steel Parts

Introduction to Precision CNC Machining Precision CNC (Computer Numerical Control) machining is a subtractive manufacturing technology that utilizes advanced computer systems to control and execute precise machining processes. The implementation…