Tool Steel Grades in CNC Machining: D2 vs. A2 – A Comprehensive Comparison?

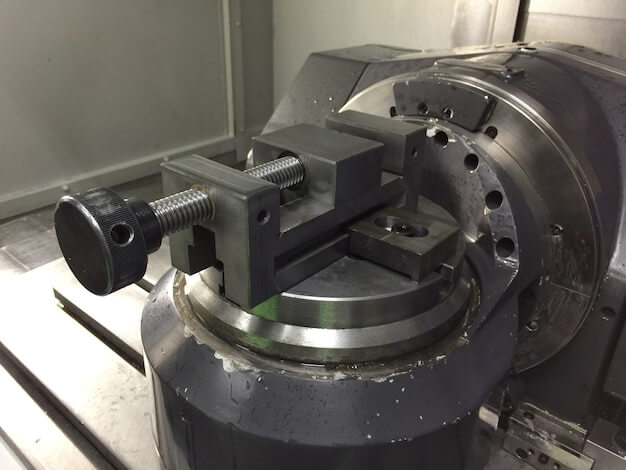

Introduction to Tool Steel In the field of machining, tool steel plays a vital role due to its unique properties. Essentially, tool steel is a type of carbon alloy steel known for its distinctive hardness, resistance to abrasion, and ability to withstand high-temperature conditions. These attributes make it highly favorable in manufacturing tools, molds, and […]

Duplex Stainless Steel vs. Super Duplex in CNC Machining: Features and Applications?

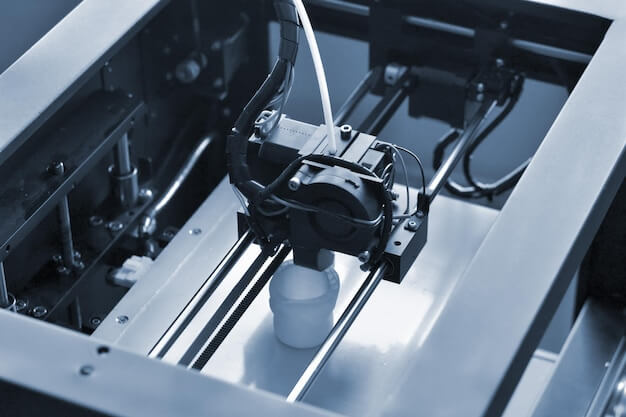

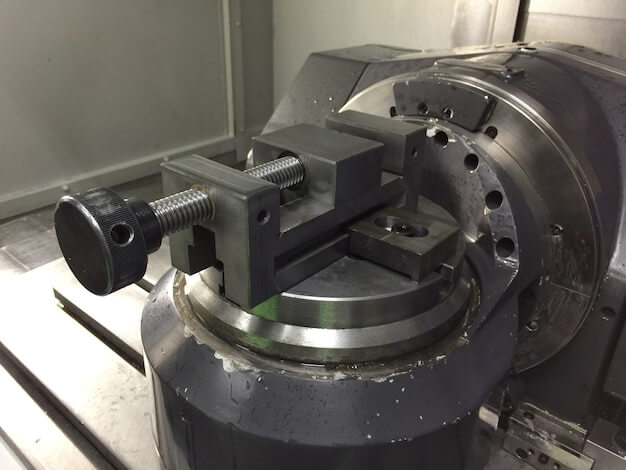

Introduction to CNC Machining and Duplex Stainless Steels In the domain of manufacturing, Computer Numerical Control (CNC) machining plays a pivotal role due to its precision, efficiency, and versatility. Essentially, CNC machining is a process used in the manufacturing sector that involves controlling machinery tools through coded instructions inputted via a computer program. The advent […]

Graphite vs. Steel: Which Material Offers Better Performance in CNC Tooling Applications?

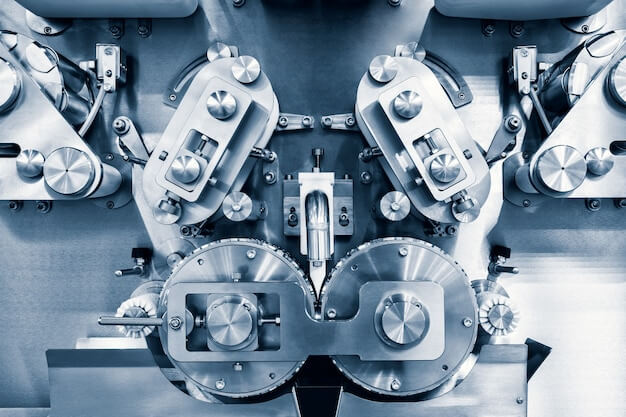

Introduction to CNC Tooling CNC tooling, an abbreviation for Computer Numerical Control tooling, is a method extensively used in the manufacturing sector. This technology automates machine tools with high-level programming commands. The row materials such as graphite and steel are turned into finished products via milling or drilling processes which are precise, repeatable and highly […]

Silicon Nitride vs. Tungsten Carbide in Precision CNC Machining: A Comparative Study?

Precision CNC Machining and the Role of Silicon Nitride vs. Tungsten Carbide Precision CNC machining is a pivotal process in manufacturing that leverages computer numerical control (CNC) for creating intricate parts with high dimensional accuracy. Key to its successful implementation are Silicon Nitride and Tungsten Carbide, two materials extensively used due their unique properties. Silicon […]

CNC Machining of Hardened Steel: Techniques and Tips for Effective Manufacturing?

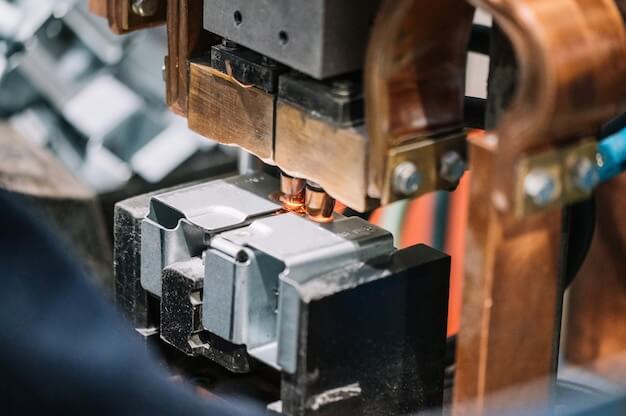

Introduction to CNC Machining The technology of Computer Numerical Control (CNC) machining has revolutionized industrial manufacturing processes. At its core, CNC machining harnesses the power of computers and advanced software for precise control over tools and machinery used in production stages. It’s widely applicable across many industries, offering unparalleled precision, consistency, and efficiency. Specifically, when […]

Is Copper the Right Choice for Electrical Component CNC Machining? A Detailed Analysis

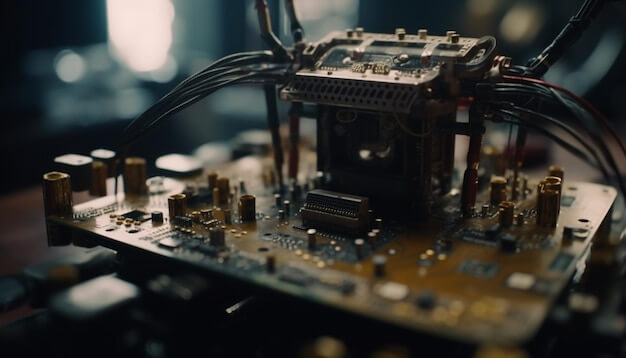

CNC Machining of Electrical Components Utilizing Copper In the field of electrical engineering, Computer Numerical Control (CNC) machining plays an integral role, particularly in the development and manufacturing of electrical components. CNC machining is a precise, automated process that involves creation or modification of parts using computer programming to control machine tools, resulting in highly […]

Hardened Steel vs. Pre-Hardened Steel in CNC Machining: What’s the Difference?

CNC Machining: Hardened Steel vs Pre-Hardened Steel Computer Numerical Control (CNC) machining is a crucial method in the manufacturing industry, known for its ability to produce complex and high-precision parts with remarkable speed and repetition. Its importance can’t be understated as it forms an essential backbone of various industries including automotive, aerospace, and medical sectors. […]

Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate control over process variables such as speed and position. One essential component used in CNC machining is ceramic tooling. Despite its multiple advantages like superior […]

Tool Steel Grades for CNC Machining: D2 vs. A2 – A Comparative Study?

Introduction to CNC Machining and Tool Steel CNC machining, or computer numerical control machining, is a manufacturing method that employs pre-programmed software to direct the activity of factory tools and machinery. A critical element in this process is tool steel, an extremely hard type of high alloy steel commonly used in cutting and drilling operations. […]

Lead-Free Brass in CNC Machining: Pros, Cons, and Comparisons?

Introduction to Lead-free Brass in CNC Machining CNC (Computer Numerical Control) machining, a prevalent method in the manufacturing sector, uses pre-programmed software to control the movement of factory machinery and tools. This process enables the production of complex three-dimensional parts with a high level of precision. In recent years, there has been a shift towards […]

High-Speed Steel vs. Carbide in CNC Tooling: Life Span and Performance Showdown?

Introduction to High-Speed Steel and Carbide in CNC Tooling In the world of Computer Numerical Control (CNC) tooling, two materials have emerged as key players: high-speed steel (HSS) and carbide. HSS, which contains elements such as tungsten, molybdenum, vanadium, and chromium, is known for its versatility and toughness while carbide, a composite of carbide particles […]

Molybdenum Alloys in Precision CNC Machining: Applications and Advantages?

Molybdenum Alloys and Precision CNC Machining: An Introduction Molybdenum alloys, known for their high melting point and thermal conductivity, are integral to the world of precision Computer Numerical Control (CNC) machining. CNC machining is a subtractive production method that uses computer-controlled machines to remove material from workpieces and fashion them into desired parts. Designed with […]