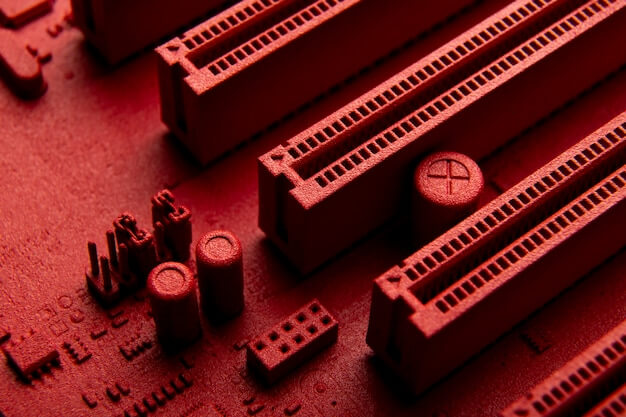

Ceramics in CNC Machining: Are They as Effective as Metals?

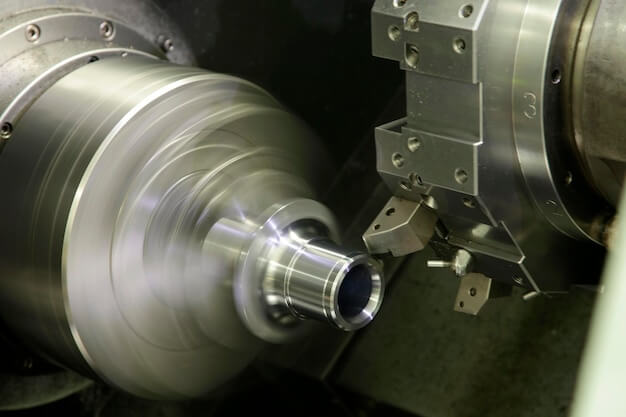

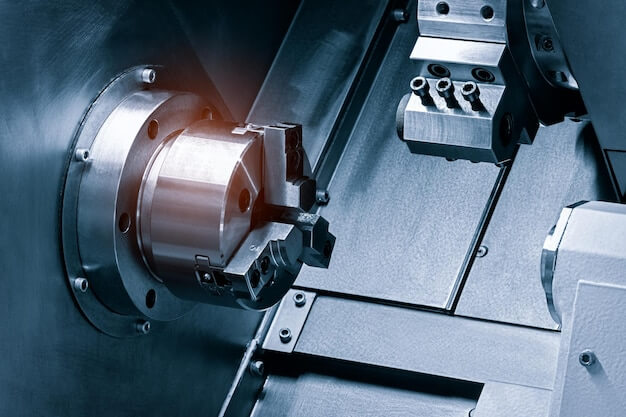

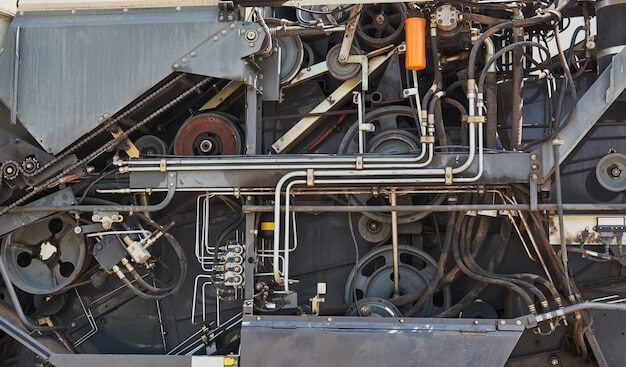

Introduction to CNC Machining and Ceramics CNC machining, or Computer Numerical Control machining involves the use of computers to control machine tools in the manufacturing process. This highly efficient method allows for precise cutting, drilling, milling, and other operations on a variety of materials, including ceramics. The growing usage of ceramics in the field of […]

Titanium Grade 5 vs. Grade 23 in CNC Machining: Which is the Superior Choice?

Introduction: Understanding Titanium Grades and Their Importance in CNC Machining Titanium, a metallic element well-known for its high strength and low weight, is categorized into different grades based on its chemical composition. Two of the popularly used titanium grades in Computer Numerical Control (CNC) machining are Grade 5 and Grade 23. These grades offer varied […]

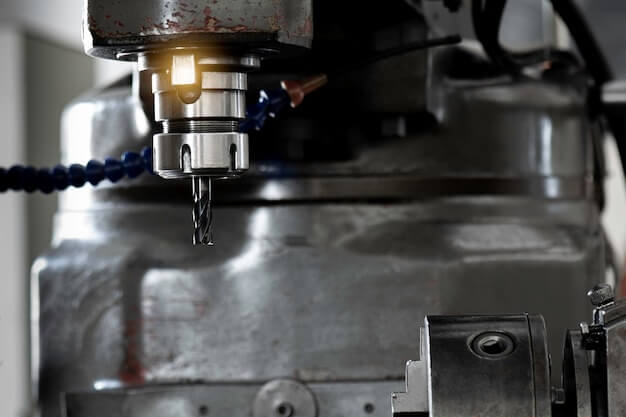

High-Speed Steel vs. Carbide in CNC Tooling: Life Span and Performance Showdown?

Introduction to High-Speed Steel and Carbide in CNC Tooling In the world of Computer Numerical Control (CNC) tooling, two materials have emerged as key players: high-speed steel (HSS) and carbide. HSS, which contains elements such as tungsten, molybdenum, vanadium, and chromium, is known for its versatility and toughness while carbide, a composite of carbide particles […]

Molybdenum Alloys in Precision CNC Machining: Applications and Advantages?

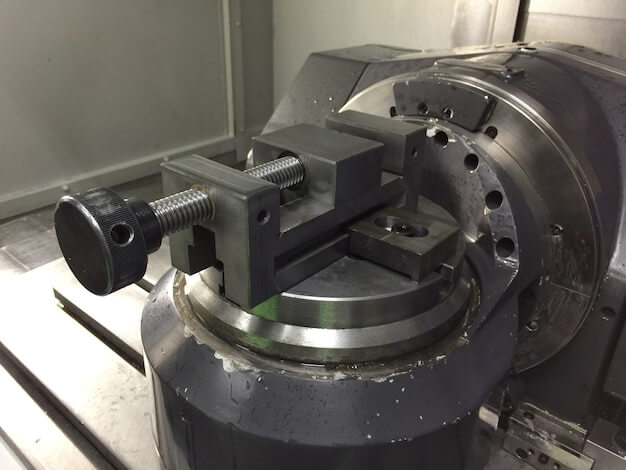

Molybdenum Alloys and Precision CNC Machining: An Introduction Molybdenum alloys, known for their high melting point and thermal conductivity, are integral to the world of precision Computer Numerical Control (CNC) machining. CNC machining is a subtractive production method that uses computer-controlled machines to remove material from workpieces and fashion them into desired parts. Designed with […]

CNC Machining for Aerospace: Titanium vs. Aluminum Alloys – A Critical Comparison?

CNC Machining for Aerospace: Titanium vs. Aluminum Alloys In the world of aerospace engineering, Computer Numerical Control (CNC) machining plays a pivotal role in manufacturing high-precision components needed for modern aircraft. Using this technology provides accuracy and efficiency that manual operations cannot match. Two widely adopted materials in this industry are titanium and aluminum alloys. […]

CNC Machining in the Energy Sector: Selecting Materials for Wear Resistance and Longevity

Introduction to CNC Machining in the Energy Sector CNC machining, an acronym for Computer Numerical Control machining, is a manufacturing process where pre-programmed computer software dictates the movement of factory machinery. This technology can manipulate 3D cutting tasks with exceptional precision and enables automatic control of machining tools such as mills, lathes, grinders, and routers. […]

The Impact of Machining Parameters on the Performance of Titanium Alloys in Aerospace Components

Introduction: Titanium and its uses in Aerospace Components Titanium, a metallic element known for its strength and light weight, plays a significant role in the aerospace sector. Stronger than steel yet lighter in weight, titanium alloys exhibit excellent resistance to corrosion, endure extreme temperatures and withstand high pressures; characteristics which make them ideal for critical […]

The Role of Titanium in CNC Machining: Benefits and Challenges Explained

Introduction: CNC Machining and the Role of Titanium In the realm of Computer Numerical Control (CNC) machining, each metal utilized possesses distinctive characteristics that cater to specific applications. An essential player in this diverse matrix is Titanium – a high-strength, lightweight metal known for its exceptional corrosion resistance. Often favored in industries such as aerospace […]

Material Choices for High-Volume CNC Machining: Balancing Cost and Performance

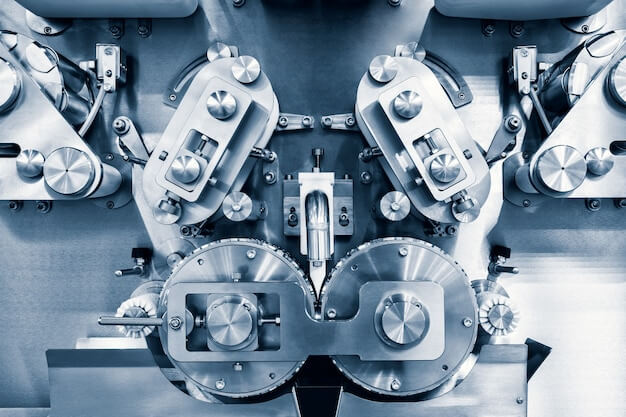

Introduction to CNC Machining CNC machining stands as a cornerstone in modern manufacturing, offering precision and repeatability that are unmatched by manual processes. At its core, CNC (Computer Numerical Control) machining involves the use of computers to control machine tools, which shape and form materials into desired parts. The challenge often faced in this field […]

The Evolution of CNC Machining: 3D Printing Metals vs. Traditional Machining Materials

Introduction to CNC Machining and 3D Printing CNC machining and 3D printing stand as pivotal technologies in the manufacturing sector, each playing a unique role in how objects are created. CNC (Computer Numerical Control) machining is a process where pre-programmed computer software dictates the movement of factory tools and machinery, allowing for the precise cutting, […]

Evaluating the Machinability of Nickel Alloys in CNC Processes

Introduction to Nickel Alloys and CNC Processes Nickel alloys, a class of materials renowned for their robustness and versatility, are used extensively in various sectors such as aerospace, chemical processing, nuclear systems etc. Offering superior resistance to corrosion, high-temperature degradation and stress, they represent an invaluable asset in crafting parts that require high reliability in […]

High-Speed Steel vs. Carbide in CNC Tooling: Which is Better for Your Manufacturing Needs?

The Importance of Choosing the Right Material for CNC Tooling in Manufacturing In the manufacturing industry, choosing the right material for Computer Numerical Control (CNC) tooling is crucial. Every manufacturer aims at achieving efficiency, accuracy, and durability while keeping costs under control. Therefore, making an informed decision on whether to go for High-Speed Steel or […]