Diamond machining has emerged as a game-changer in the realm of precision manufacturing. While traditional cutting methods have their limitations, the relentless development of new techniques and equipment has paved the way for CNC machine tools to approach the precision offered by abrasive methods. This article delves into the world of diamond machining, exploring its advantages, techniques, tools used, suitable materials, and real-life applications.

Why Diamond Machining Matters

When it comes to CNC machining, the hardness of the cutting tool is a critical parameter. And there is nothing harder than diamond. Artificial diamonds, known for their remarkable hardness, can withstand high temperatures and cutting regimes with ease. Moreover, they offer cost-effectiveness and deliver superior surface finishes that rival those achieved by expensive grinding and polishing machines. By mounting diamonds on simple CNC machine tools and optimizing the technological system for maximum rigidity, exceptional results can be obtained, even when working with the toughest metals. Diamond turning and diamond milling have become popular technologies in the commercial sector due to their ability to deliver outstanding outcomes.

The Advantages of Diamond Machining

Diamond machining offers a myriad of advantages, making it an attractive choice for various applications:

- Outstanding Aluminum Machining: Diamond tools excel at withstanding high cutting speeds and temperatures, making them ideal for mass-producing aluminum parts. When machining aluminum, a single diamond insert can outlast multiple carbide tools.

- Hard Alloy Production: Diamonds, being the hardest material, are invaluable for processing carbide, ceramics, and other highly resistant materials. The hardness of diamonds enables efficient cutting through softer materials.

- Diamond Polishing: Diamond cutters are not only used for cutting but also for polishing transparent materials like glass, polycarbonate, and PMMA. The fine diamond grains at the tip of the tool ensure impeccable results and excellent surface finishes.

- Durability: Diamond tool inserts exhibit exceptional durability, lasting 30-50 times longer than their carbide counterparts. This longevity significantly reduces downtime and increases productivity.

- Superior Surface Finish: By employing diamond machining techniques for high-quality machining, manufacturers can achieve better surface finishes compared to conventional tools. Diamond tools introduce a small grinding feature into the machining process, enhancing the overall outcome.

Diamond Machining Techniques

While many diamond machining methods involve grinding and polishing, two techniques stand out for their cutting-focused implementation with CNC equipment:

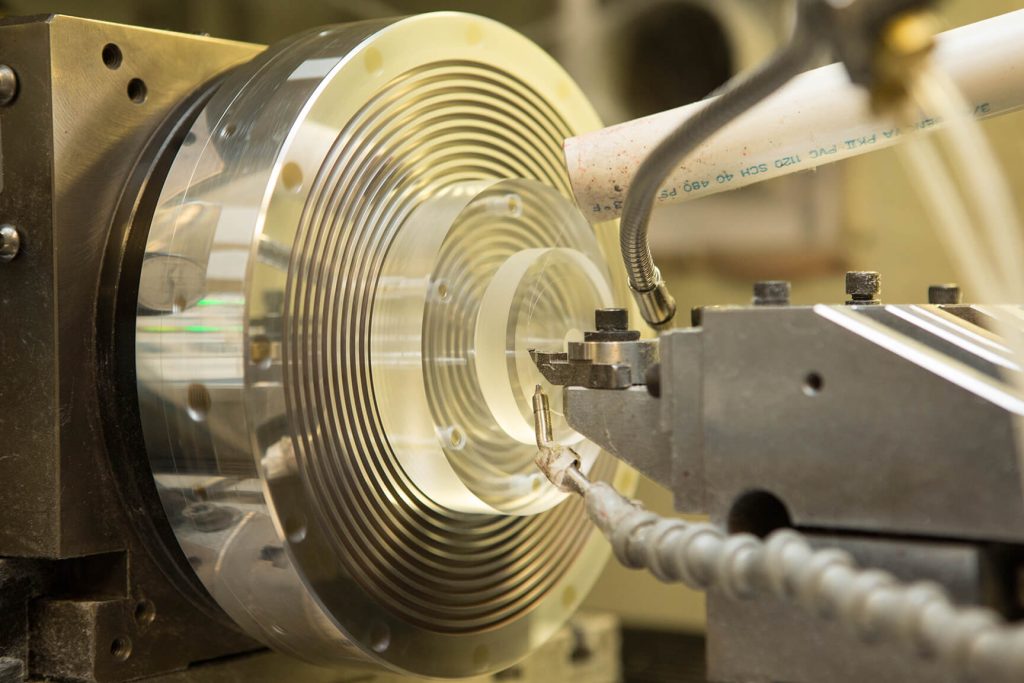

1. Single-Point Diamond Turning (SPDT)

Single-Point Diamond Turning (SPDT) closely resembles simple turning but employs a diamond-tipped cutter as the tool. To ensure optimal results, the manufacturing system must exhibit enhanced rigidity. This involves minimizing the lengths between fixtures, using shorter tool supports, and minimizing vibrations. SPDT proves especially useful for manufacturing optical lenses, which often require clear and transparent surfaces.

2. Single-Point Diamond Milling (SPDM)

Single-Point Diamond Milling (SPDM) shares similarities with conventional milling but utilizes a mill with diamond-tipped inserts. When mounted on a 5-axis machining center, this mill becomes the perfect tool for processing complex surfaces made of glass, PMMA, and polycarbonate. Achieving exceptional surface finishes for automotive lamp lenses, light guides, and customized window panes is possible with an extremely fast-revolving diamond mill, controlled cutting feed, and abundant lubrication. Minimizing vibrations is crucial for preserving the quality of the final piece. Some SPDM techniques involve uni-directional machining, ensuring the cutting force always operates in one direction.

Tools Used in Diamond Machining

A diamond machining tool follows the same structure as any other cutting tool, with the primary difference lying in its insert. The insert comprises a tungsten or carbide base material with a thindiamond film on its tip. This diamond film is exceptionally hard and can last up to 50 times longer than conventional tools. It provides a sharp cutting edge, resulting in precise and clean cuts that yield supreme surface finishes.

Materials Suitable for Diamond Machining

Diamond tools are highly versatile and can proficiently process a wide range of materials, including:

- Ceramics: Diamond machining is effective in shaping and finishing ceramic materials, harnessing their inherent strength and hardness.

- Silicone: With its unique properties, silicone can be efficiently machined using diamond tools, allowing for precise and intricate designs.

- Polycarbonate: Diamond machining offers excellent results when working with polycarbonate, ensuring high-quality finishes and dimensional accuracy.

- Plexiglass (PMMA): Transparent materials like plexiglass benefit from diamond machining, as it enables the creation of clear, polished surfaces.

- Non-ferrous Alloys: Diamond tools are ideal for processing non-ferrous alloys such as aluminum, copper, bronze, and titanium, offering exceptional precision and surface finishes.

- Glass: Diamond machining allows for precise shaping and finishing of glass materials, making it an essential technique in glass manufacturing.

- Polymers: Various polymers like ABS and polyethylene can be effectively machined using diamond tools, enabling intricate designs and high-quality finishes.

- Highly Abrasive Materials: Diamond tools excel in processing highly abrasive materials such as concrete, granite, and stone, providing precise and efficient machining solutions.

From hard and brittle substances to soft and transparent materials, diamond machining offers versatility and exceptional results across a broad spectrum of materials.

When Diamond Machining is Not Suitable

It is important to note that diamond tools are not suitable for cutting steel or iron alloys. The reason behind this limitation lies in the presence of carbon atoms in both diamond and steel. During machining, when exposed to high temperatures, carbon atoms in both materials can cause sintering, leading to the tool sticking to the workpiece and rendering both components unusable. It is crucial to choose alternative machining methods when working with steel or iron alloys.

Applications Where Diamond Machining Excels

Diamond machining has proven its worth in various real-life applications. Some notable examples include:

- Lamp Lens Prototypes: Diamond machining is instrumental in manufacturing car lamp lens prototypes. These prototypes often feature complex geometries that make grinding impractical. By utilizing a diamond-tipped mill with a 5-axis CNC machine, manufacturers can achieve mirror-like surfaces with the desired quality, even for large and intricate lens designs.

- Light Guides: Light guides are critical components used to illuminate specific spots in a complex manner. They require both precise surface finishes and intricate geometries. With advanced CNC milling machines capable of 3-axis, 4-axis, or even 5-axis micro-milling, diamond machining technology enables the production of various types of light guides and lenses with excellent optical quality in array or freeform patterns.

These real-life applications showcase the transformative power of diamond machining, enabling manufacturers to achieve exceptional results in terms of surface quality, precision, and complex geometries.

Embracing the Potential of Diamond Machining

Diamond machining continues to evolve and open new possibilities in precision manufacturing. As technology advances, we can expect further refinements and innovations in diamond machining techniques. The relentless pursuit of precision and surface quality drives the ongoing development of this technique. With its exceptional advantages, versatility, and ability to achieve superior surface finishes, diamond machining has firmly established itself as a shining star in the world of manufacturing. By leveraging diamond tools and employing appropriate machining techniques, manufacturers can unlock new avenues of precision and excellence in their products.

Recommended Reads:

- The 5-Step Guide to Mastering CAM in CNC Machining

- 4 Remarkable Uses of CNC Plasma Cutters

- Common Mistakes to Avoid When Writing G-Code

- 5 G-Code Commands Every CNC Machinist Needs to Know

- 4 Must-Know CAM Software for CNC Machining

Related Posts

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Impeller five-axis CNC precision machining technology

The impeller is the most important part on the rotor, and is generally composed of a wheel disc, a wheel cover and a blade. An integral impeller is an impeller…

- Understanding Bead Blasting in CNC Machining(cnc g code Jacqueline)

CNC (Computer Numerical Control) machining is a dominant method employed for multiple manufacturing systems across the globe. From healthcare to aerospace, this technology has revolutionized how we manufacture products. One…