Copper C110 vs. Brass C360: Which Metal Wins in Electrical Conductivity and Machinability?

Introduction: Understanding Copper C110 and Brass C360 The comprehensive understanding of the distinct properties of metals is cardinal in various industries, particularly those involving electronics and manufacturing. Among these are two common metal alloys extensively utilized due to their unique characteristics – Copper C110 and Brass C360. On one hand, Copper C110 contains at least […]

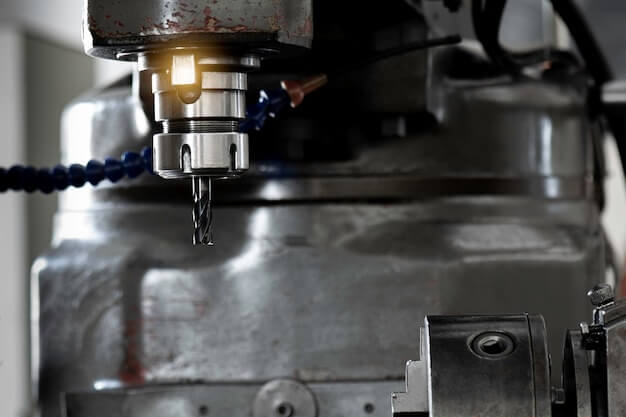

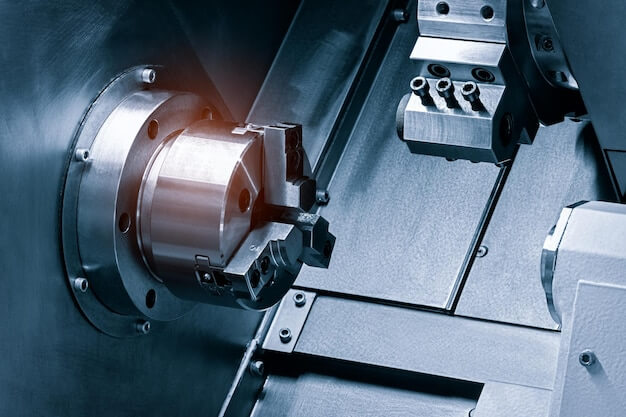

Graphite vs. Steel Tooling in CNC Machining: Which Material Offers Better Precision and Durability?

Introduction: Overview of CNC Machining and Importance of Material Selection in Tooling In the world of Computer Numerical Control (CNC) machining, the choice of tooling material plays a vital role in both precision and durability. This sector utilizes programmed tools to manufacture components with high accuracy and repeatability. The selection of the right materials affects […]

CNC Machining for Aerospace: Titanium vs. Aluminum Alloys – A Critical Comparison?

CNC Machining for Aerospace: Titanium vs. Aluminum Alloys In the world of aerospace engineering, Computer Numerical Control (CNC) machining plays a pivotal role in manufacturing high-precision components needed for modern aircraft. Using this technology provides accuracy and efficiency that manual operations cannot match. Two widely adopted materials in this industry are titanium and aluminum alloys. […]

Ceramic CNC Machining: Advantages and Limitations for Industrial Applications?

Ceramic CNC Machining: Advantages and Limitations for Industrial Applications As the demand for precision in industrial applications continues to rise, manufacturers have turned to advanced solutions like Computer Numerical Control (CNC) machining to meet this need. Specifically, Ceramic CNC Machining has become increasingly vital due to its unique benefits and few limitations. Ceramics are inorganic […]

The Role of Magnesium Alloys in Reducing Weight for Automotive CNC Machined Parts?

The Importance of Weight Reduction in Automotive Manufacturing and the Role of CNC Machining In automotive manufacturing, weight reduction stands as a pivotal factor influencing fuel efficiency and performance. Lighter vehicles facilitate improved mileage and acceleration along with decreased greenhouse gas emission, which makes it an eco-friendly solution. One essential technique that has emerged to […]

The Advantages of Using High-Speed Steel (HSS) in CNC Machining

Introduction to High-Speed Steel (HSS) and CNC Machining High-speed steel, commonly known as HSS, is a type of alloy that boasts superior hardness, toughness, and heat resistance. These characteristics make it the material of choice for various industrial applications such as cutting tools. On the other hand, Computer Numerical Control or simply CNC machining, refers […]

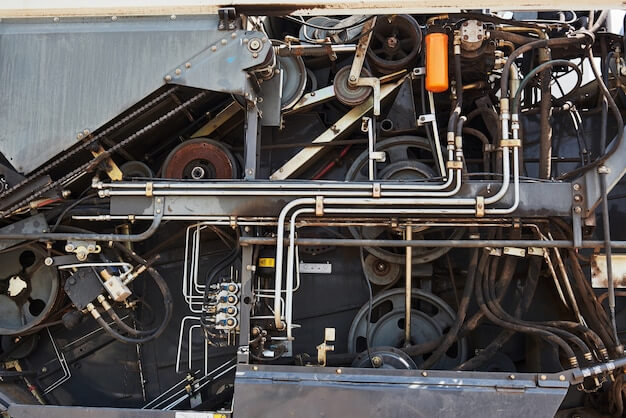

CNC Machining in the Energy Sector: Selecting Materials for Wear Resistance and Longevity

Introduction to CNC Machining in the Energy Sector CNC machining, an acronym for Computer Numerical Control machining, is a manufacturing process where pre-programmed computer software dictates the movement of factory machinery. This technology can manipulate 3D cutting tasks with exceptional precision and enables automatic control of machining tools such as mills, lathes, grinders, and routers. […]

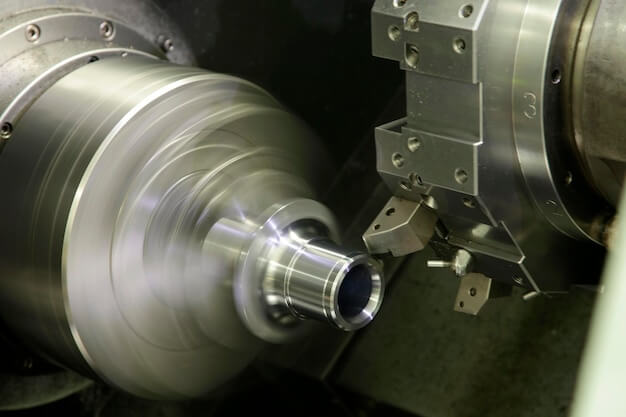

The Impact of Machining Parameters on the Performance of Titanium Alloys in Aerospace Components

Introduction: Titanium and its uses in Aerospace Components Titanium, a metallic element known for its strength and light weight, plays a significant role in the aerospace sector. Stronger than steel yet lighter in weight, titanium alloys exhibit excellent resistance to corrosion, endure extreme temperatures and withstand high pressures; characteristics which make them ideal for critical […]

Enhancing Optical Components with CNC Machining: Glass vs. Polycarbonate

Introduction to CNC Machining CNC (Computer Numerical Control) machining stands as a pivotal technology in the manufacturing of optical components, enabling the precise shaping of materials with minimal human intervention. This process is crucial for creating intricate parts used in various optical applications, from lenses to mirrors. Focusing on materials like glass and polycarbonate, CNC […]

The Role of Titanium in CNC Machining: Benefits and Challenges Explained

Introduction: CNC Machining and the Role of Titanium In the realm of Computer Numerical Control (CNC) machining, each metal utilized possesses distinctive characteristics that cater to specific applications. An essential player in this diverse matrix is Titanium – a high-strength, lightweight metal known for its exceptional corrosion resistance. Often favored in industries such as aerospace […]

Material Choices for High-Volume CNC Machining: Balancing Cost and Performance

Introduction to CNC Machining CNC machining stands as a cornerstone in modern manufacturing, offering precision and repeatability that are unmatched by manual processes. At its core, CNC (Computer Numerical Control) machining involves the use of computers to control machine tools, which shape and form materials into desired parts. The challenge often faced in this field […]

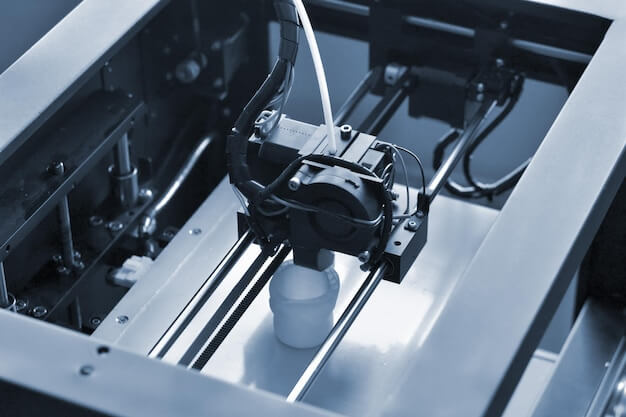

The Evolution of CNC Machining: 3D Printing Metals vs. Traditional Machining Materials

Introduction to CNC Machining and 3D Printing CNC machining and 3D printing stand as pivotal technologies in the manufacturing sector, each playing a unique role in how objects are created. CNC (Computer Numerical Control) machining is a process where pre-programmed computer software dictates the movement of factory tools and machinery, allowing for the precise cutting, […]