Blog

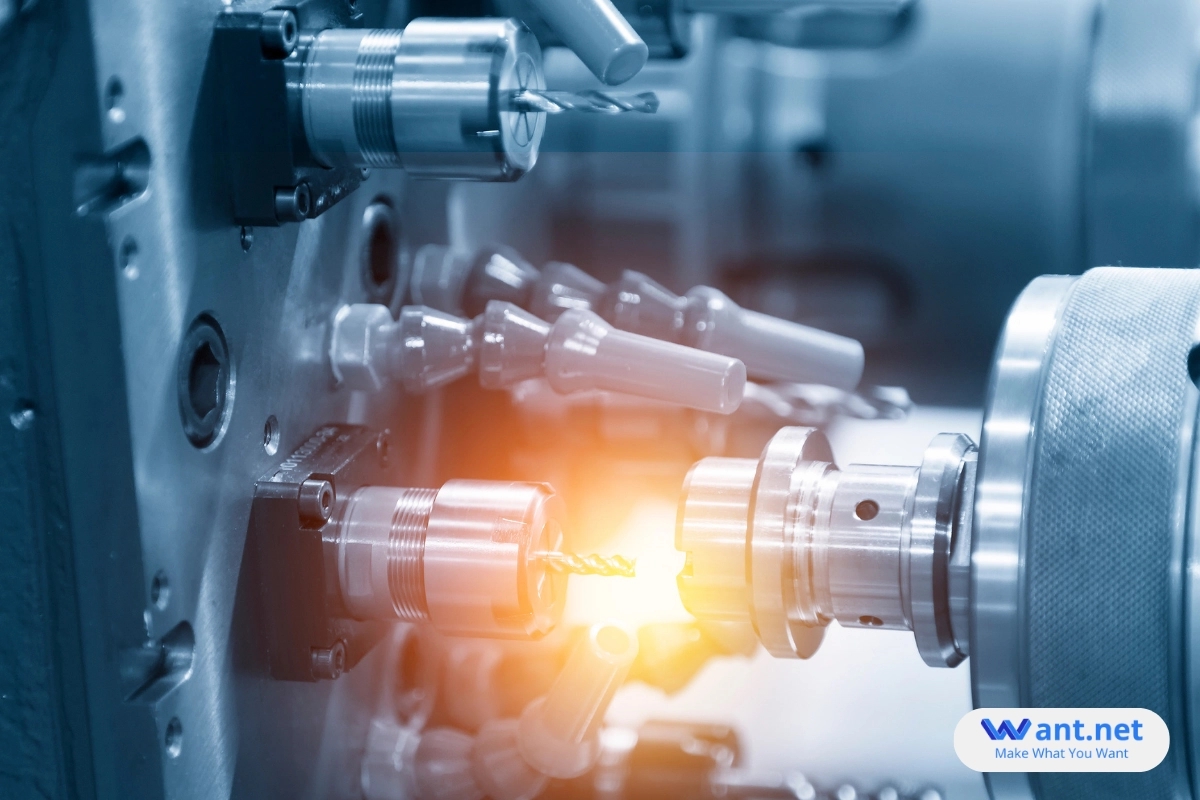

Top 10 CNC Turning Centers in the USA in 2023

There are many factors to take into account while selecting a CNC turning center. The most important factors are the machine’s quality, warranty, and manufacturer

What Is Metal CNC Machining Service Cost? (2023)

CNC machining is a modern and demanding industry nowadays. CNC machining is primarily used to produce speedy prototypes, exact CNC machined parts, technical instruments, and

The Application of Machining Parts in New Energy Vehicles

As the new energy vehicle market grows more global, efforts to include data-driven manufacturing technologies and modern machining tools will grow in order to satisfy

10 Advantages of CNC Machining for Custom Parts

CNC machining services produce high-quality parts with accuracy and efficient production. These CNC machines use computer numerical control machining tools to cut and shape materials

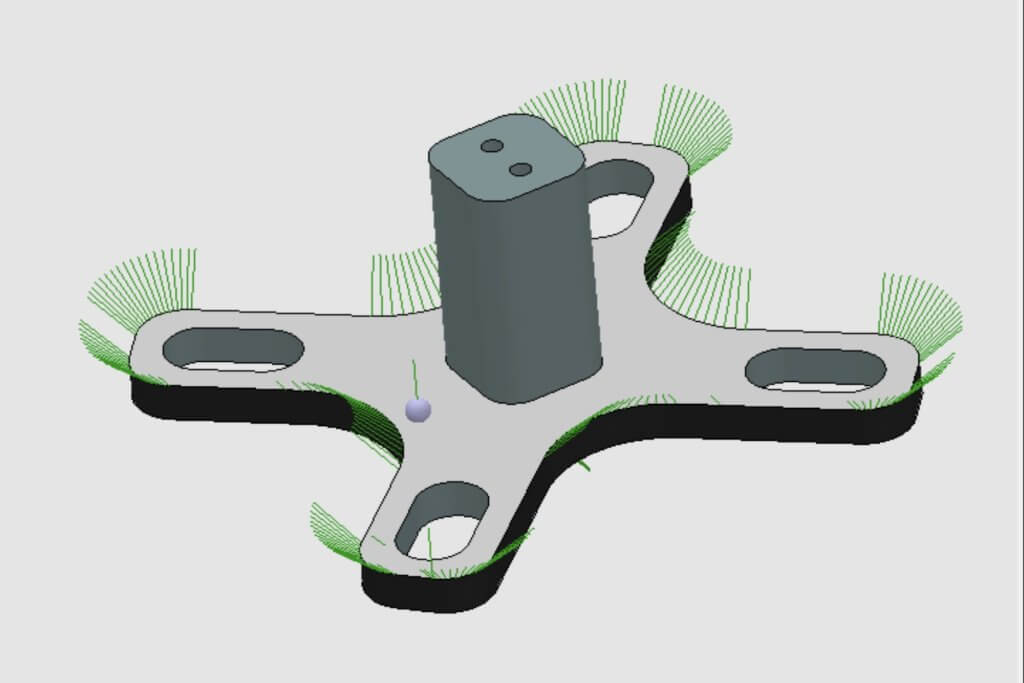

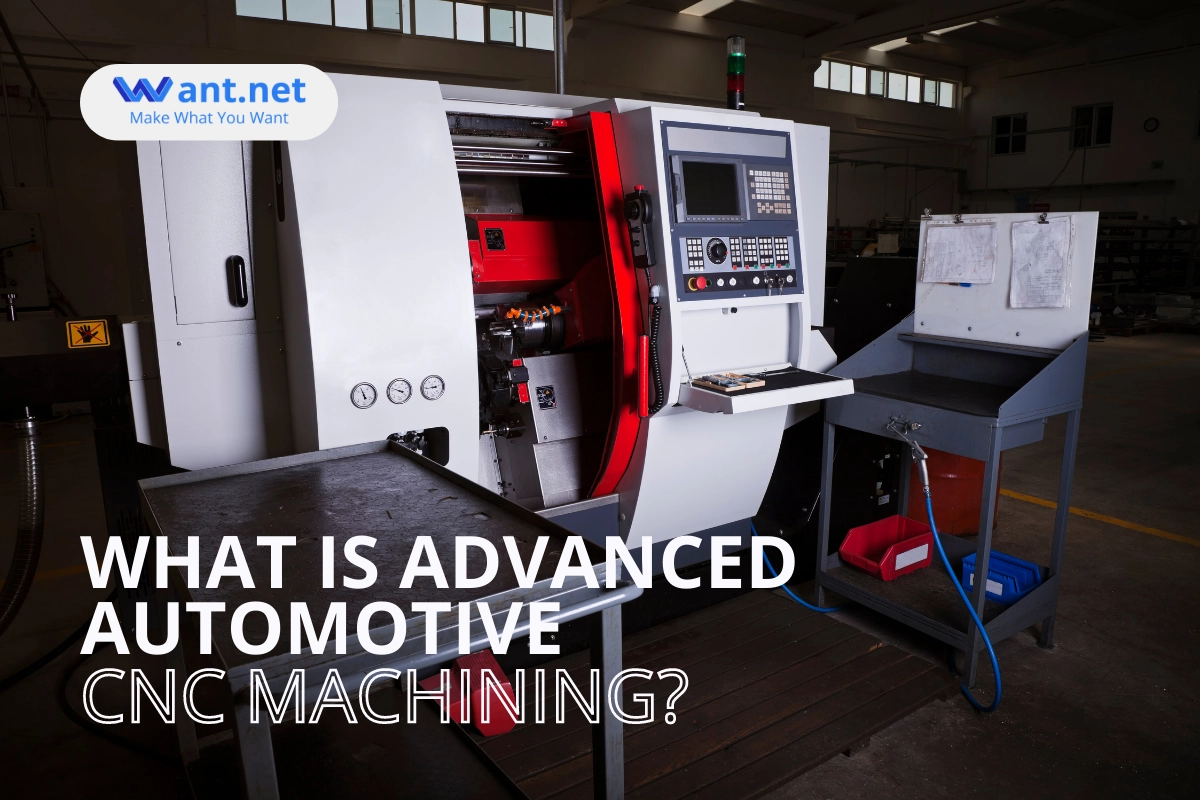

What is Advanced CNC Automotive Machining?

An advanced CNC machine works with a computer numerically controlled machine capable of accurately performing drilling, milling, turning, and grinding operations. Advanced CNC machining has altered

Hire CNC Machining Shop for Custom Parts: 10 Tips

Custom CNC machining is expected to reach US$ 31790 million by 2028 with a CAGR of 6.1%. It can be challenging to choose a CNC machining

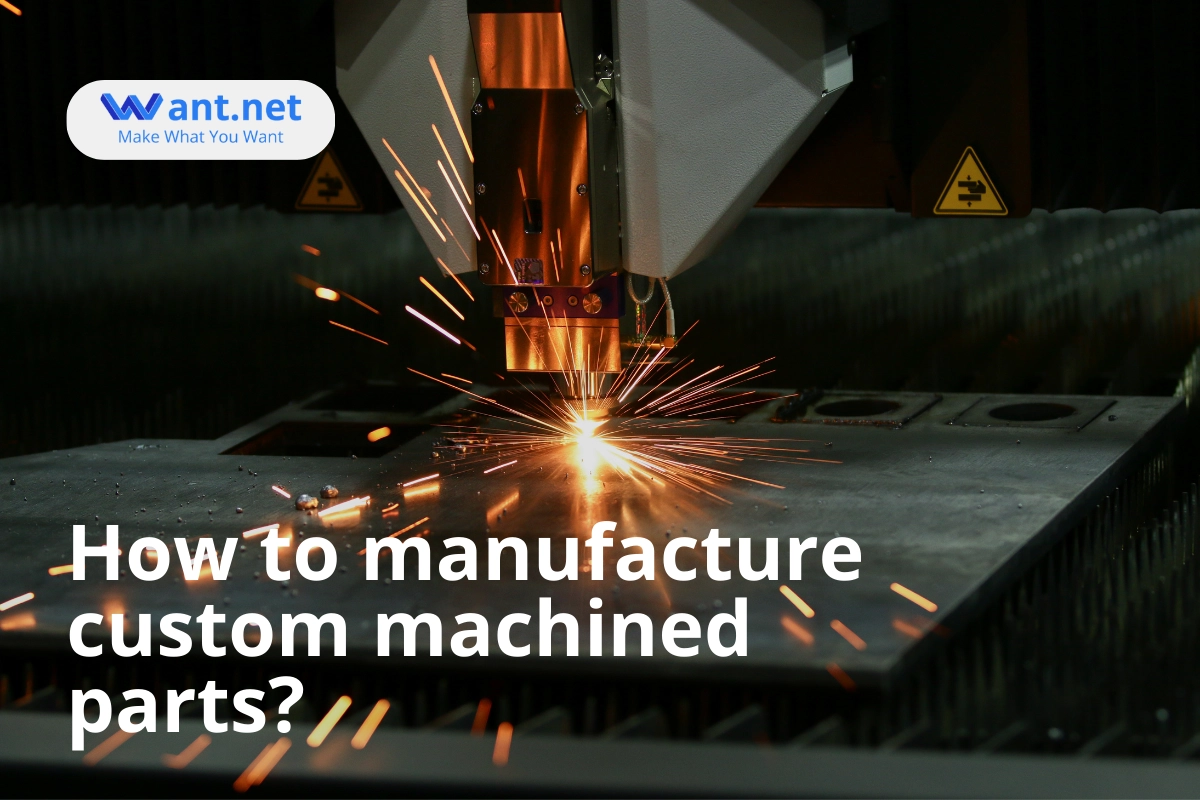

How to manufacture custom CNC machined parts?

CNC machining is a versatile process that can produce custom parts in various materials, including metals, plastics, and composites. If you need to manufacture custom

7 CNC Machining Advantages: Trends & Cost in 2023

Precision CNC Machining Introduction According to Precedent Research, there will be a massive expansion of the CNC industry by 2030. There will be 5 major

Injection Molding Vs 3D Printing: Cost | Pros & Cons (2023)

Injection molding is expected to develop at a compound annual growth rate of roughly 6.2% over the next five years. Its growth is primarily driven

3 Axis Vs 5 Axis CNC Machining: Custom Precision Parts Cost

In modern custom CNC machining services, the need for high precision customized machining parts is rising. No doubt, COVID-19 has also put an impact on the

CNC Milling Definition | Types | Process for Custom Metal Parts (2023)

According to a report published on 30 January 2023, CNC milling services requirement will cross US$ 110,203 millions by 2033. It is due to the

What Is Surface Finish in CNC Machining? Pros & Cons | Applications 2023

Surface finish is the texture, roughness, and precision of a machined surface on a part in CNC machining. It impacts the part’s appearance and performance and

Top CNC Machining Companies in China 2024 Guide

It won’t be wrong if we say that 2024 is the year of CNC machining companies because, according to the Global NewsWire the CNC machining industry is

Plastic Injection Molding in Medical Manufacturing: Advantages & Disadvantages

Plastic injection molding is used to make many medical products. This manufacturing process is proven reliable and can produce large quantities at low costs per

Selecting the Ideal Material for Injection Molding Tooling

When developing injection molding part designs, engineers and product designers often focus on selecting the right grade of plastic. Equally important, but sometimes overlooked, is

Zirconium vs. Titanium: Comparing CNC Machinability and Corrosion Resistance?

CNC Machinability and Corrosion Resistance: Zirconium vs Titanium The manufacturing industry often has to juggle a plethora of considerations while selecting materials for product manufacture.

The Use of Bronze Alloys in CNC Machining for Maritime Engineering: Corrosion Resistance and Durability

Bronze Alloys and CNC Machining in Maritime Engineering Maritime engineering, a field associated with the design, building and maintenance of structures used at sea, frequently

Titanium Grade 5 vs. Grade 23 for CNC Machining: Understanding the Differences and Applications?

Understanding CNC Machining and Titanium Grades CNC (Computer Numerical Control) machining is a fundamental manufacturing process in many industries. It utilizes automated controls and cutting

Zinc Alloys in CNC Machining: Benefits and Limitations

Introduction – CNC Machining and Zinc Alloys Computer Numerical Control (CNC) machining is a highly precise manufacturing process widely utilized in various industries to create

The Significance of Thermal Expansion in CNC Machining Materials

Introduction to CNC Machining and Thermal Expansion In the realm of manufacturing, Computer Numerical Control (CNC) machining stands as a modern innovation that utilizes computer

CNC Machining of Glass-Filled Plastics: Considerations for Strength and Finish

CNC Machining of Glass-Filled Plastics: An Introduction Computer Numerical Controlled (CNC) machining is a high precision manufacturing process whereby parts are rapidly milled, drilled, and

CNC Machining: Acrylic vs. Polycarbonate for Transparent Components

CNC Machining and Transparent Components Computer Numerical Control (CNC) machining is a manufacturing process in which pre-programmed computer software directs the motion of factory machinery

CNC Machining in Microelectronics: Material Precision for Component Miniaturization

Introduction to CNC Machining in Microelectronics CNC (Computer Numerical Control) machining stands as a cornerstone in the realm of microelectronics, offering unparalleled precision in the

Machinability of Invar vs. Kovar: Which Alloy Is Best for Precision Parts?

Machinability of Invar and Kovar Alloys for Precision Parts The alloys, Invar and Kovar are two materials widely used in the precision parts industry. To

Titanium Grade 5 vs. Grade 23 in CNC Machining: Which is More Efficient?

Introduction: Titanium Grade 5 vs. Grade 23 in CNC Machining In the realm of Computer Numerical Control (CNC) machining, the use of titanium-based materials is

Choosing Between 304 and 316 Stainless Steel for CNC Machining Applications

Introduction to 304 and 316 Stainless Steel in CNC Machining Applications The selection of the right grade of stainless steel is vital in Computer Numeric

Hastelloy vs. Stainless Steel in Chemical Processing Equipment: CNC Machining Perspectives?

Hastelloy vs. Stainless Steel in Chemical Processing Equipment: An Introduction In the realm of chemical processing equipment, two commonly used materials include Hastelloy and stainless

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- bits

- blasting

- bolts

- brake

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- cnc turning

- coating

- composite

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

- EDM

- electroplating

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- HDPE

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- NDT

- nipple

- nuts

- Nylon

- PCB

- PEEK

- pewter

- Plastic

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- Stainless Steel

- Steel

- stl

- stp

- Strain

- stress

- stud

- supplier

- surface finishes

- Teflon

- tempering

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- urethane

- VMCs

- washer

- Waspaloy

- watch

- yield

- Zinc

- Zirconium

Thinking of Using Satin Anodized Aluminum for CNC Parts

What Exactly Is Satin Anodized Aluminum, and Why Might You Choose It? I’ve worked with aluminum in a lot of …

Blind Rivet Installation Guide: CNC Drilling, Sizing, and Fixing Tips

Introduction When I first got into mechanical design, blind rivets were just something I saw used on factory floor panels. …

Clear Anodized Aluminum Explained: Material Benefits, Use Cases and Buying Tips

Introduction When I first came across clear anodized aluminum, I was designing a custom electronics enclosure for a client in …

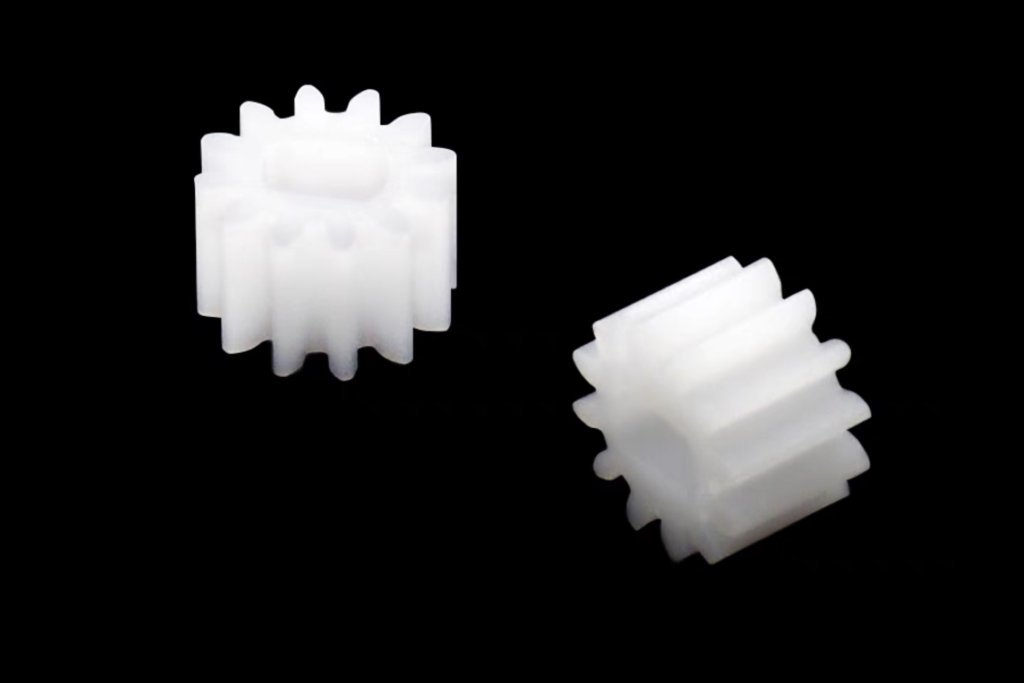

Plastic Gears Machining Guide: From Material Selection to Precision Cutting

I. Why Machine Plastic Gears Instead of Molding? Plastic gears have become essential in a wide range of industries, from …

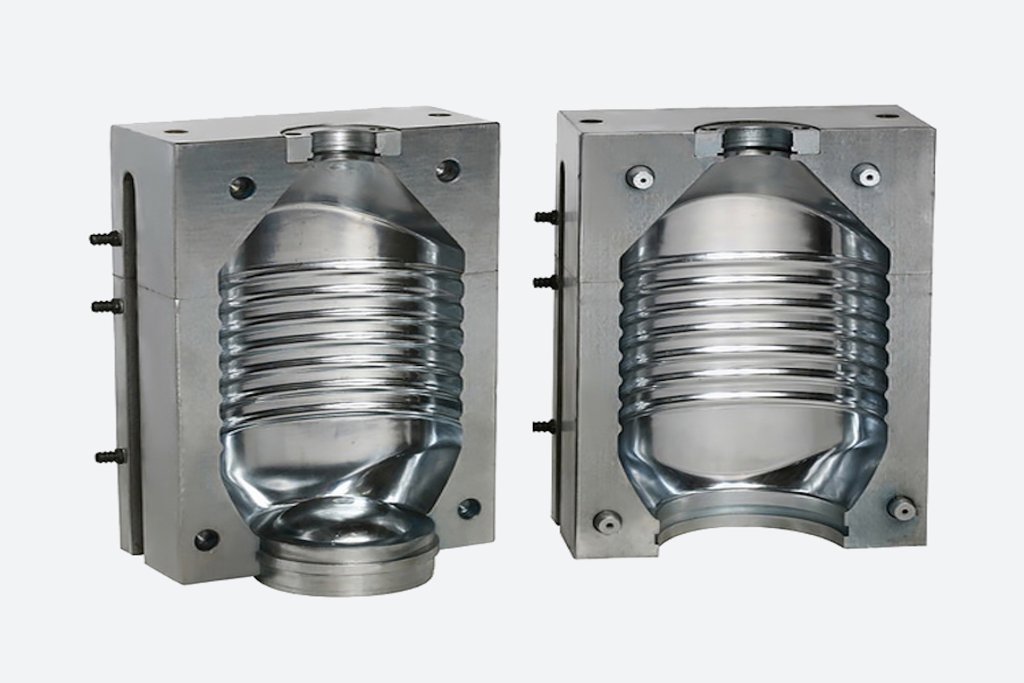

Blow Mold Machining with CNC: Precision, Speed, and Repeatability

I. Introduction Blow molding is everywhere, even if we don’t always notice it. From plastic bottles and oil cans to …

Metal Rivets and CNC Machining: From Hole Design to Final Assembly

I. Introduction Metal rivets have been around for centuries. Even in today’s high-tech, precision-engineered world, they’re still everywhere. From aircraft …

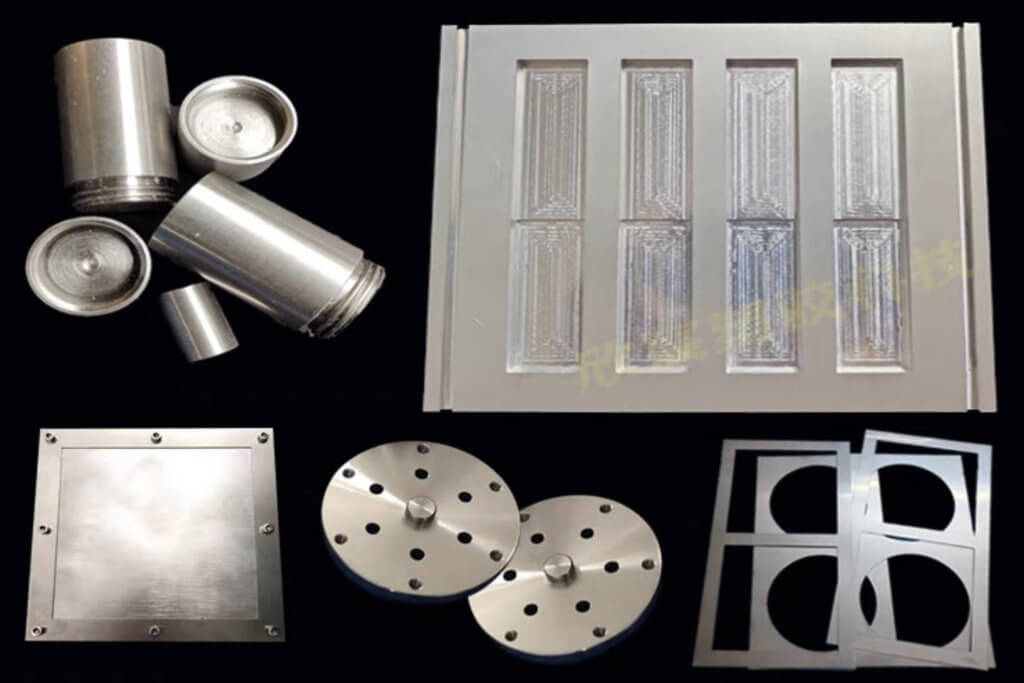

How to Make High-Precision Resin Molds : A Complete Guide for Creators

I. Introduction Creating resin molds has become one of my favorite ways to turn unique ideas into physical reality. Resin …

Plastic Rivets Prototyping and Production machining: A Modern Solution for Complex Fasteners

Understanding Plastic Rivets: Types, Uses, and Materials Plastic rivets are versatile fasteners used to join materials in various applications. Unlike …

CNC Router Bits – Selection, Use, and Buying Guide

I. Introduction to CNC Router Bits If you’ve ever worked with a CNC router, you already know the bit you …

Acetal vs Delrin for Machining: A Complete Guide for Engineers and Designers

Introduction When I first started working with plastics in CNC machining, one question kept coming up: Acetal vs Delrin – what’s …

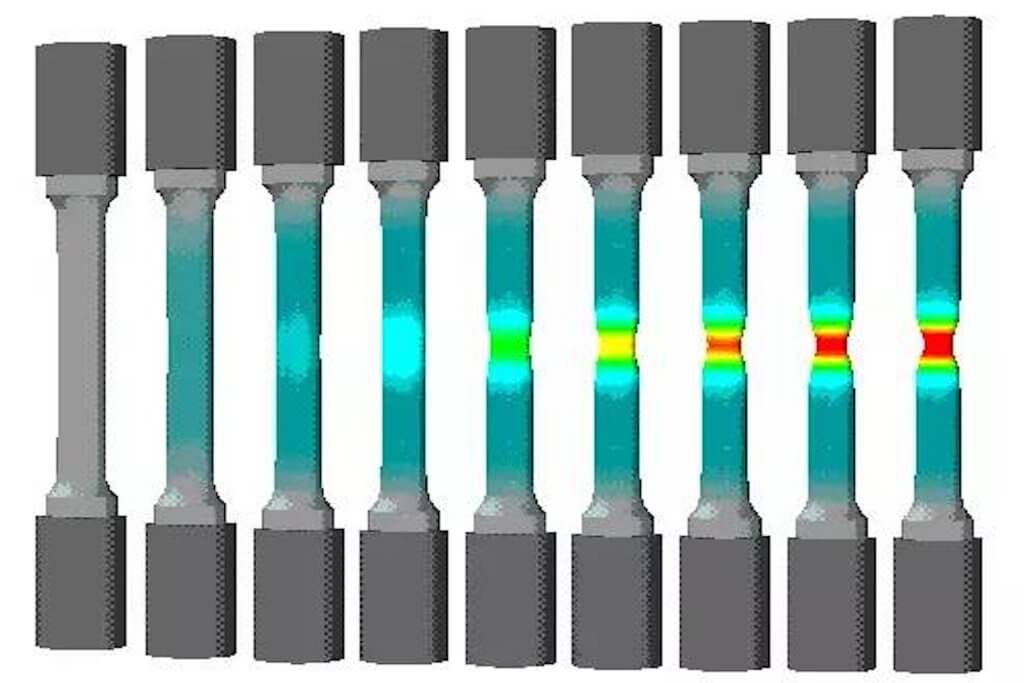

Tensile Strength of Steel Explained for Engineers and Machinist

Introduction The tensile strength of steel is the heartbeat of engineering and machining. It’s the maximum stress a steel part …

Master STL File Creation for Machining Success

Introduction STL files are the heart of CNC machining, turning digital designs into tangible parts. An STL file, short for …