Blog

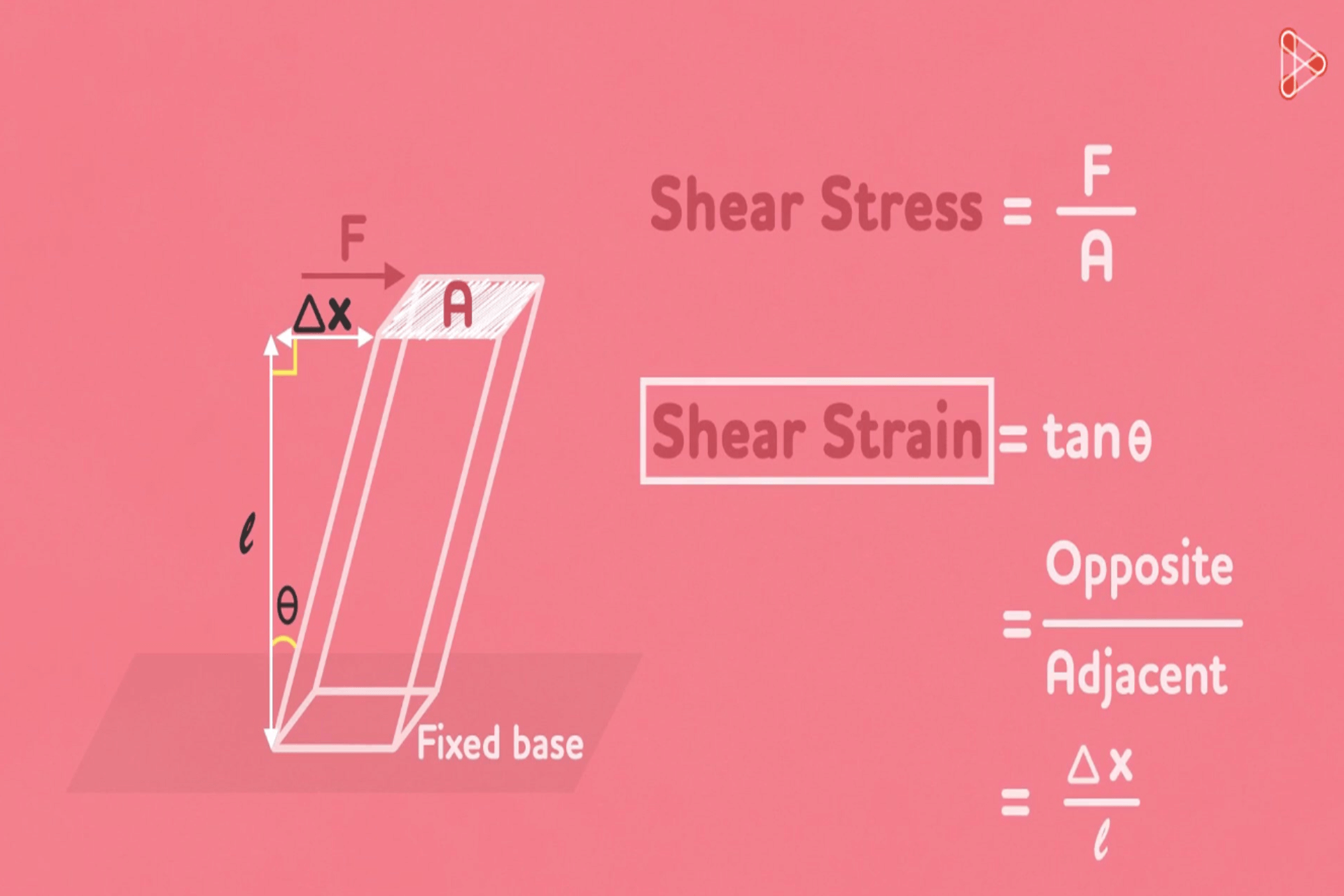

Mastering the Cut: A Definitive Guide to Shear Force in CNC Machining

Introduction As a machinist who’s spent years honing my craft in CNC machining, I’ve learned that shear force is the heartbeat of every precise cut.

Polyamide vs. Nylon: The Ultimate Engineer’s Guide to Properties, Types, and Applications

Introduction As an engineer with over a decade of experience in polymer applications, I’ve frequently tackled the polyamide vs. nylon confusion, especially when selecting materials

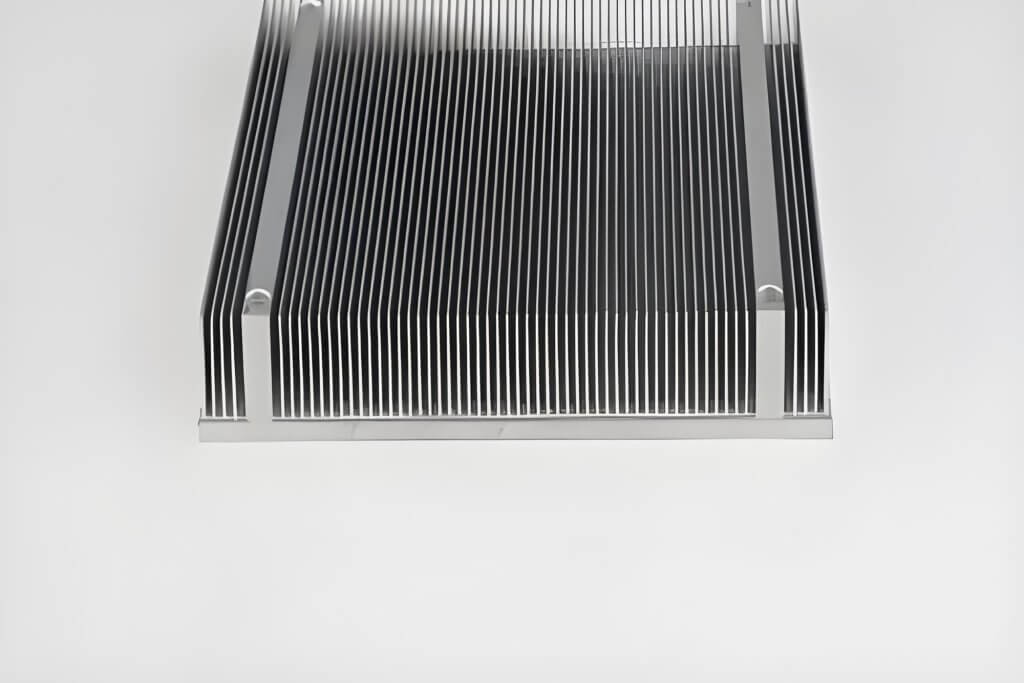

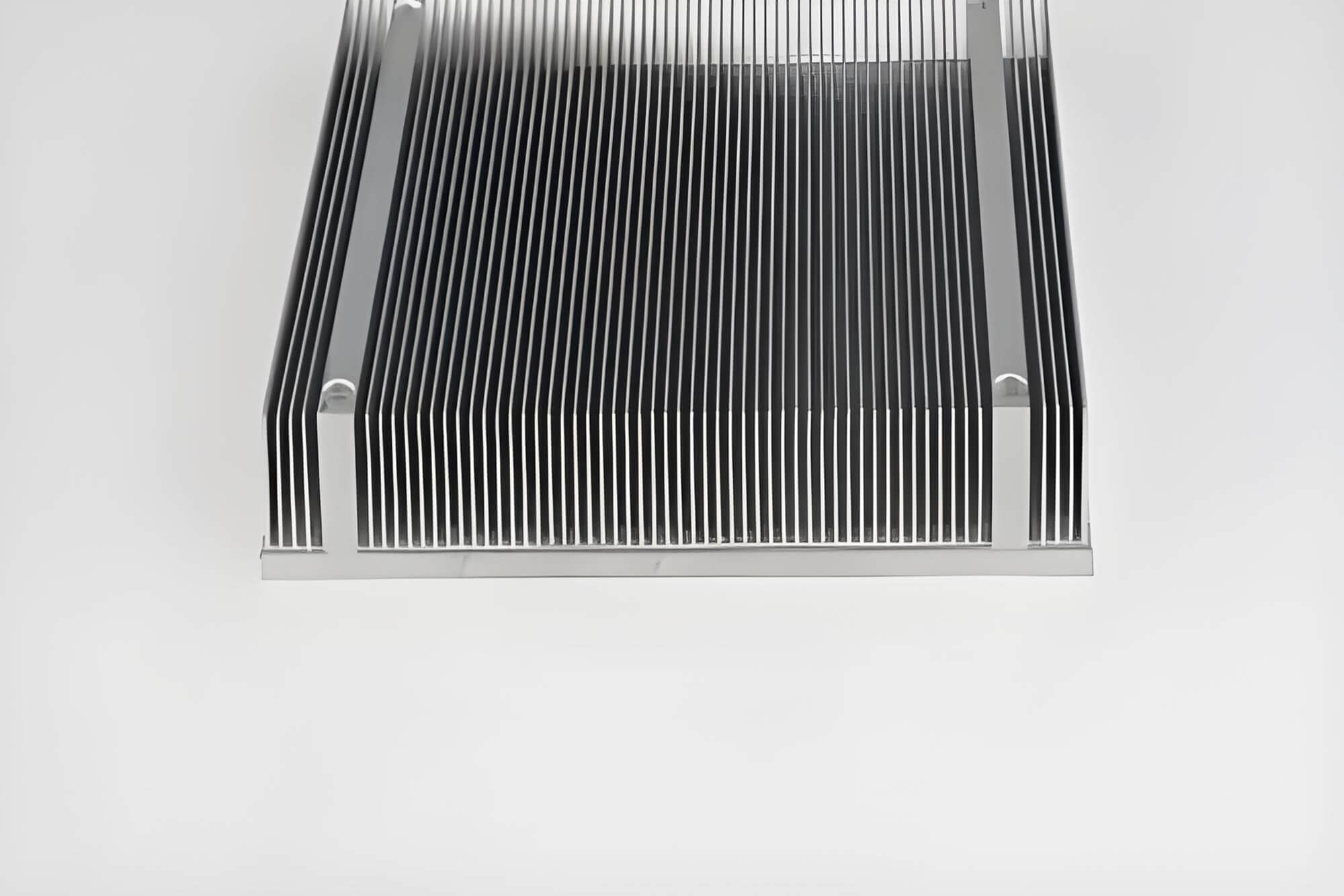

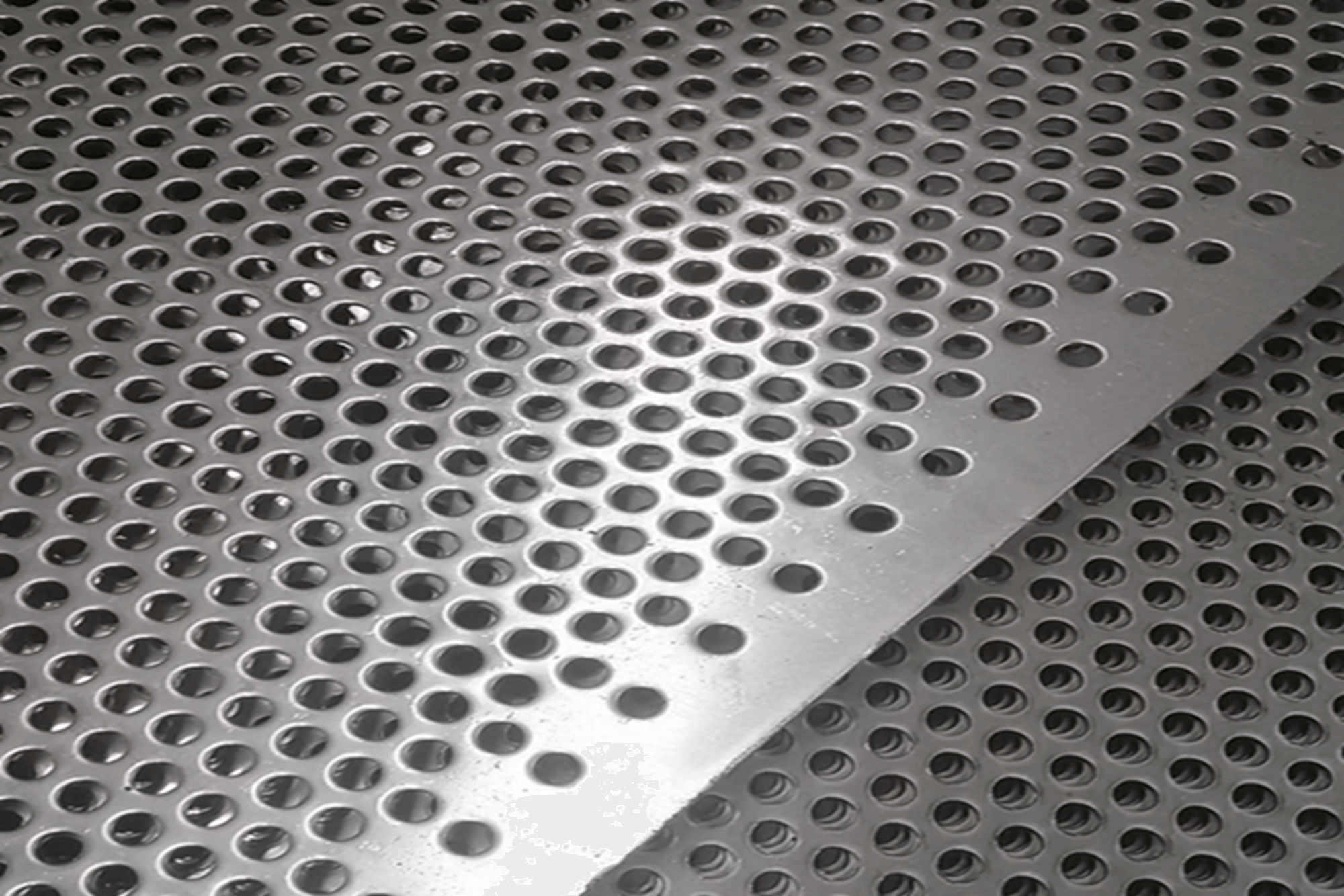

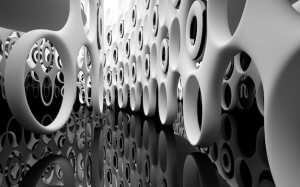

High-Performance Thermal Management: A Deep Dive into Large Heat Sinks

Introduction: As an engineer who’s spent years designing thermal solutions for data centers and renewable energy systems, I’ve seen firsthand how a large heat sink

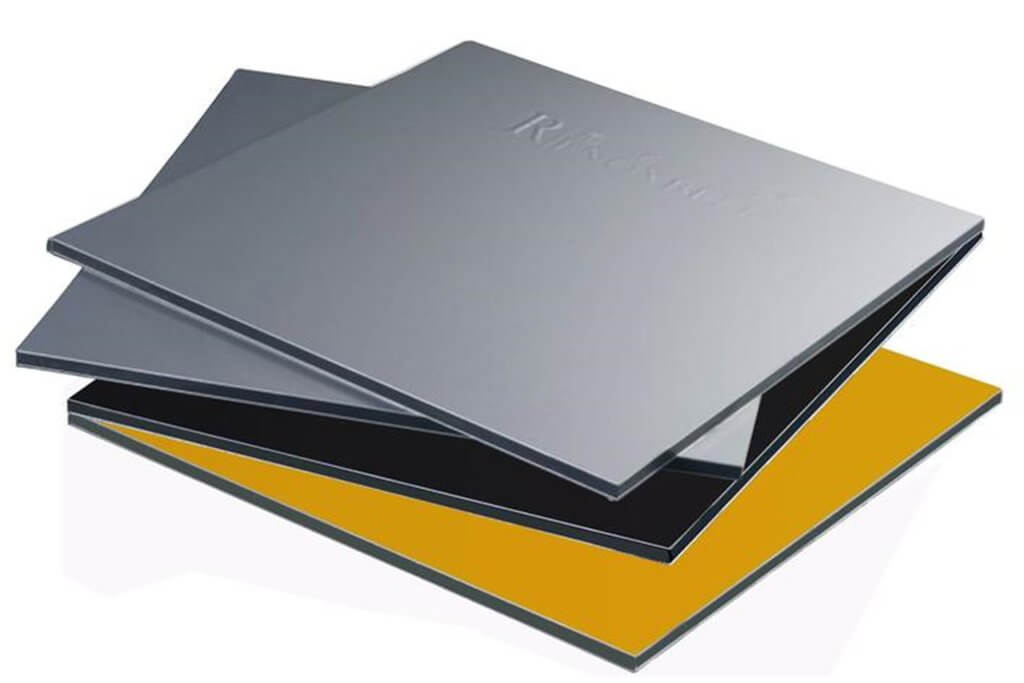

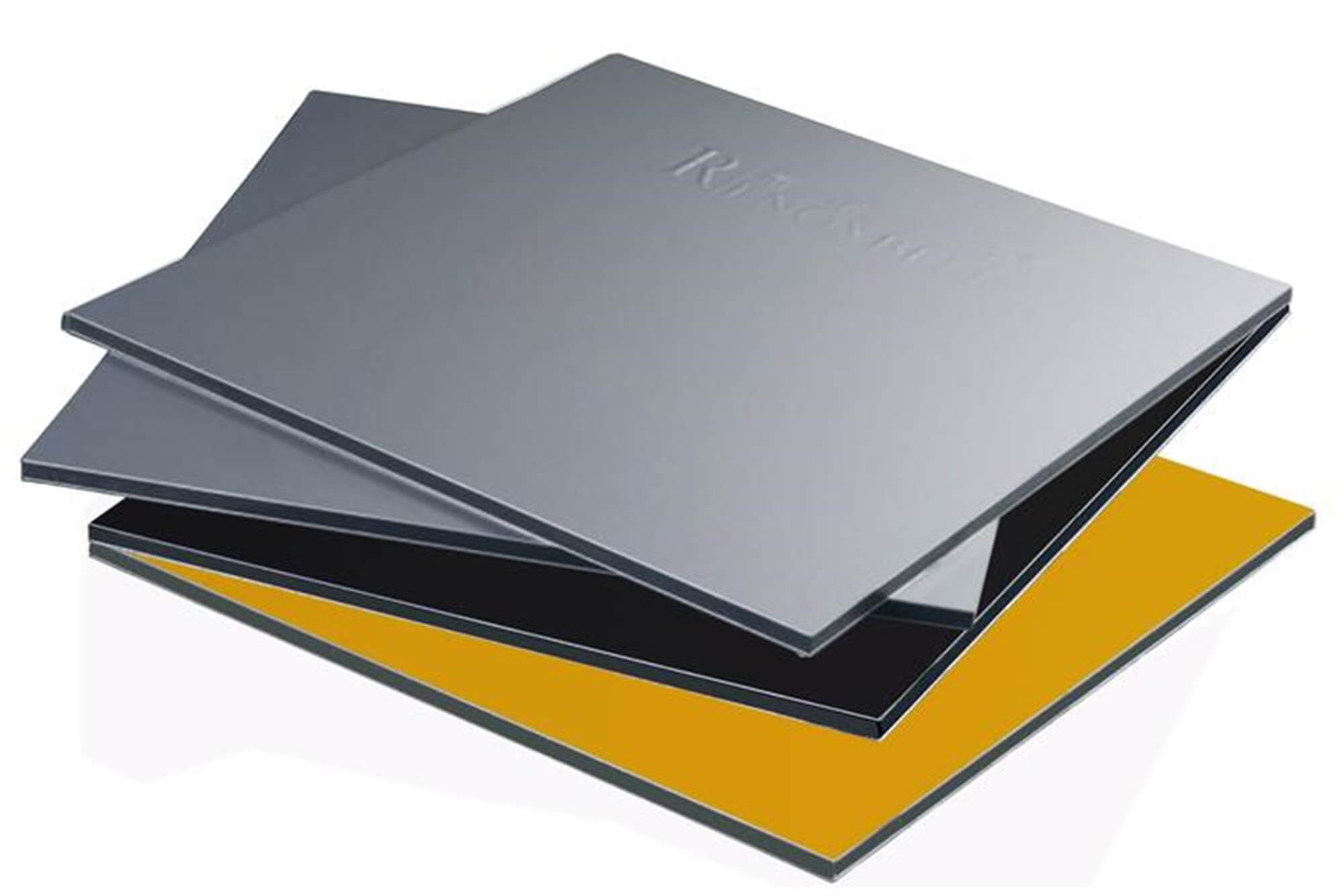

Modern Aluminum Siding: Durability, Cost, and Style for Today’s Home

The Resurgence of a Modern Classic: An Introduction to Aluminum Siding When I embarked on the journey to revamp my home’s exterior, I sought a

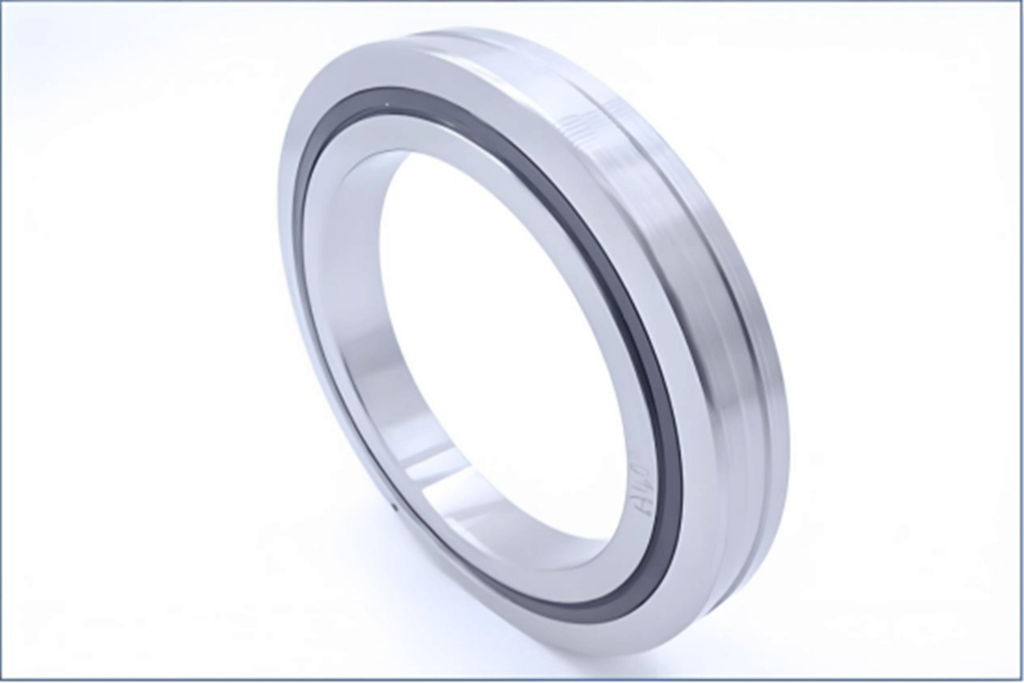

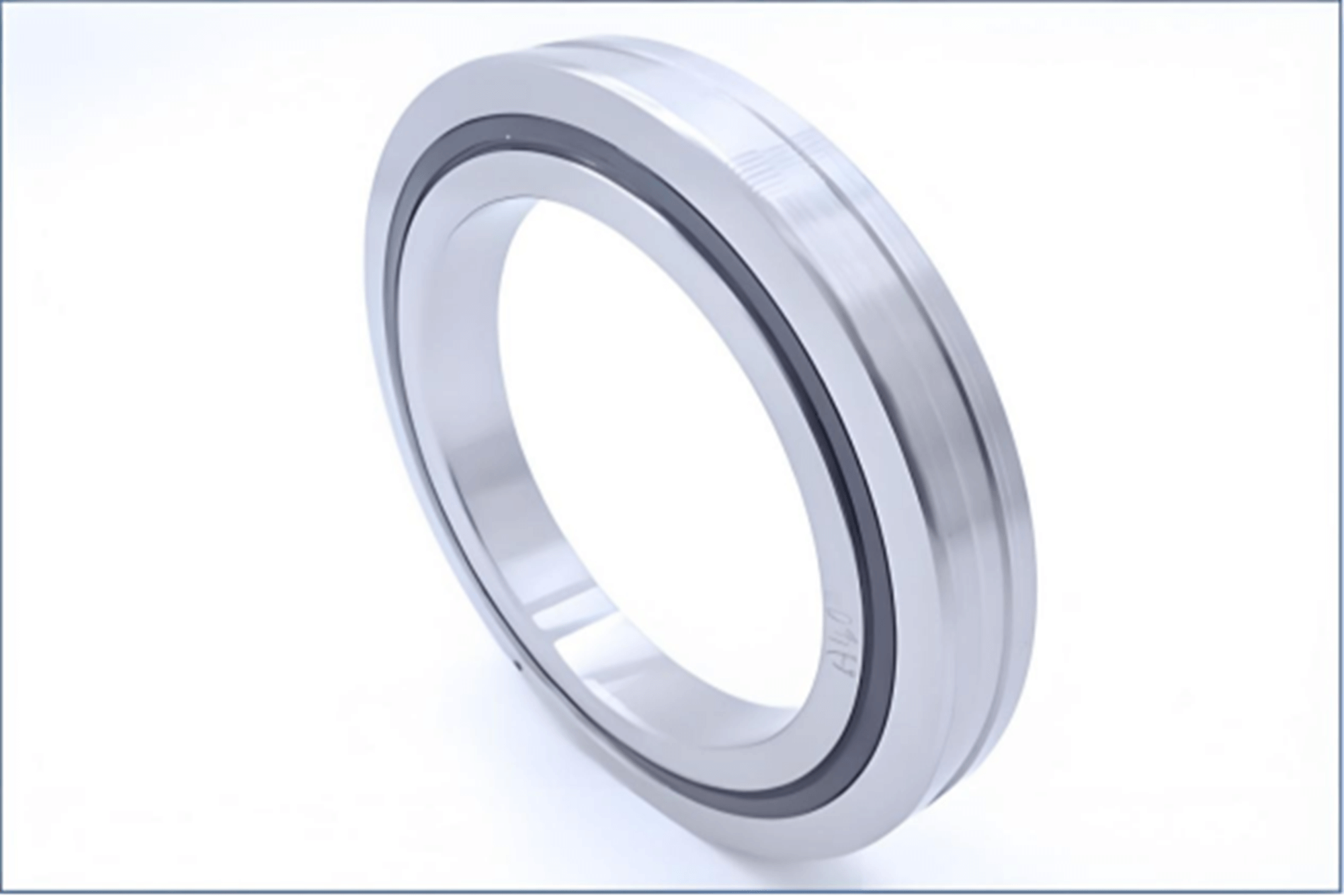

The Definitive Engineer’s Guide to Crossed Roller Bearings: Precision, Rigidity, and System-Level Integration

Introduction In the pursuit of precision, rigidity, and compact designs, crossed roller bearings are pivotal in advancing engineering fields like robotics, medical imaging, and machine

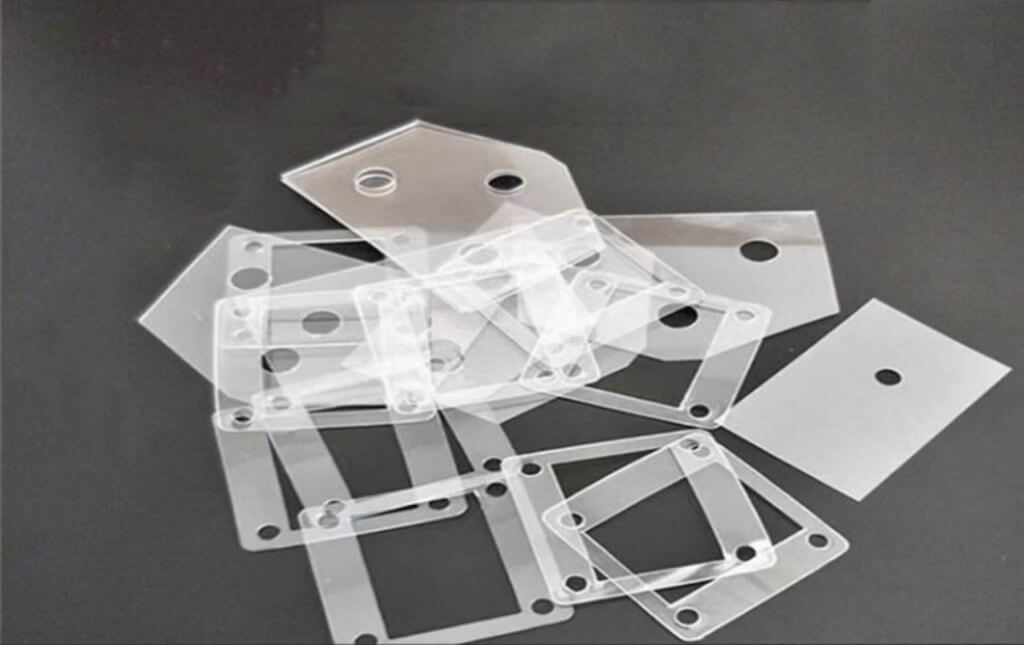

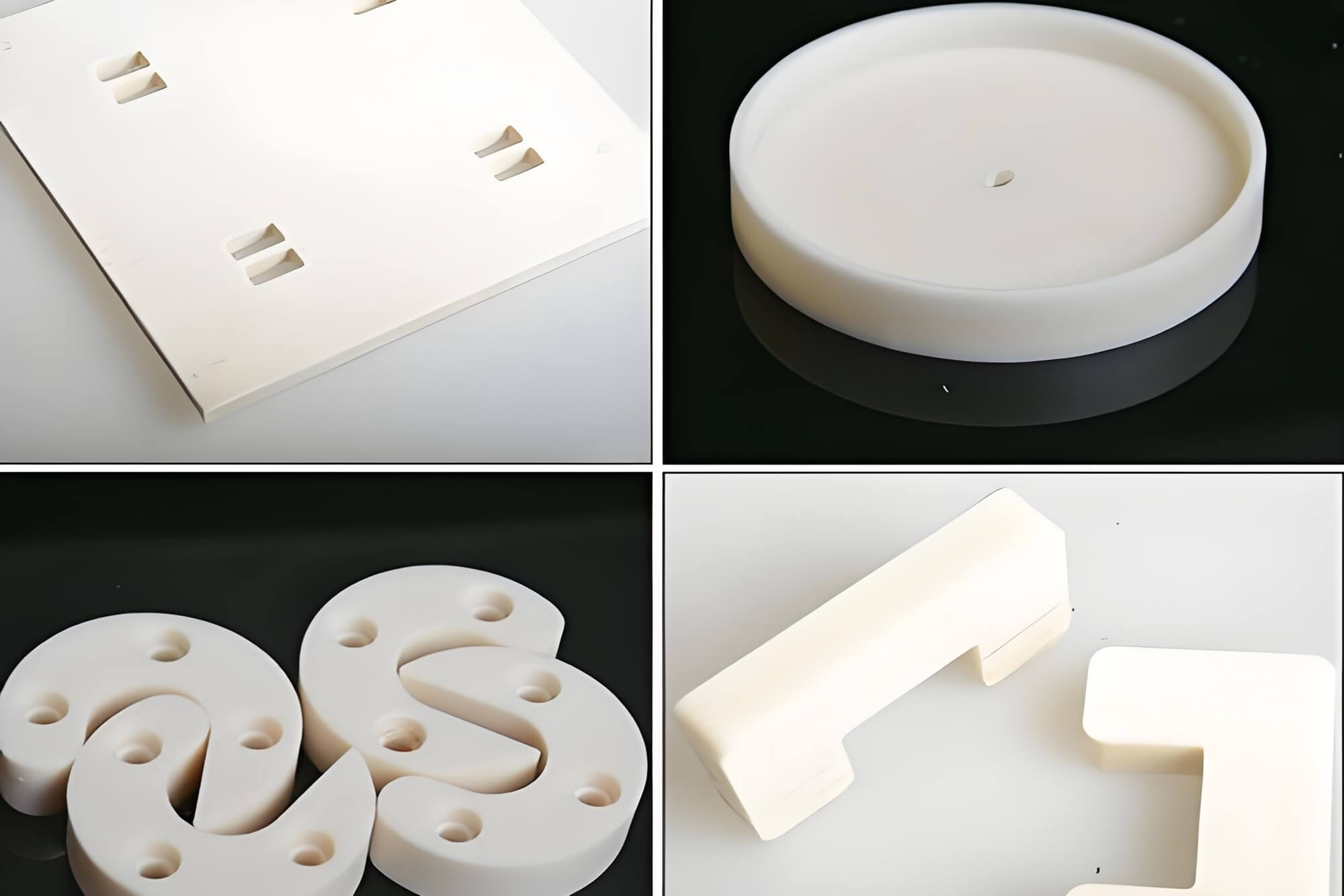

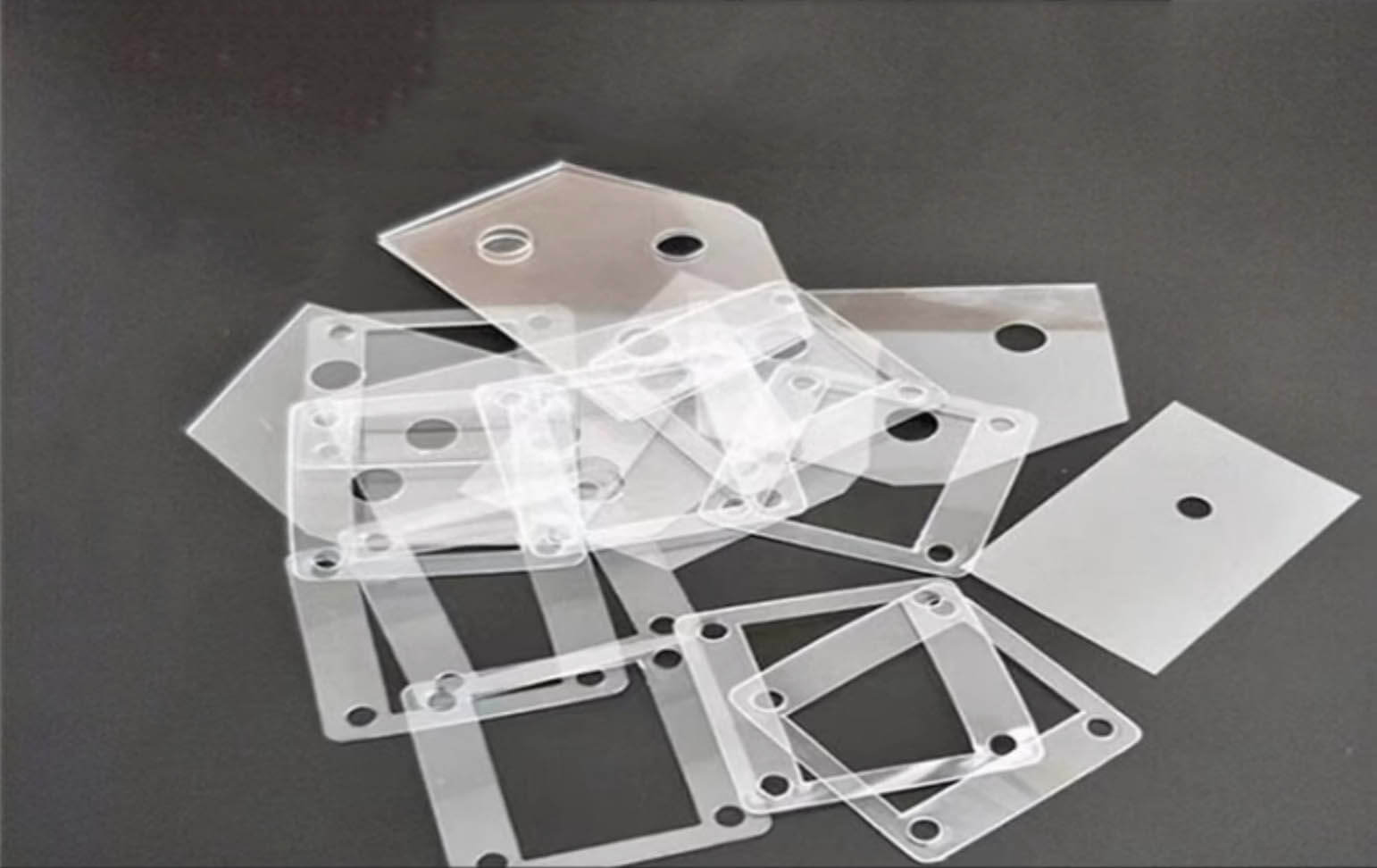

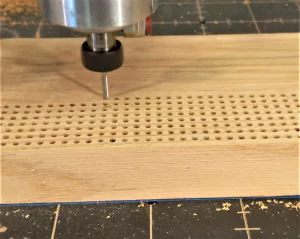

Plastic Shims: How to Make Custom Parts with CNC Machines

Introduction Plastic shims are one of those components you don’t think much about—until you really need them. I first got into making custom plastic shims

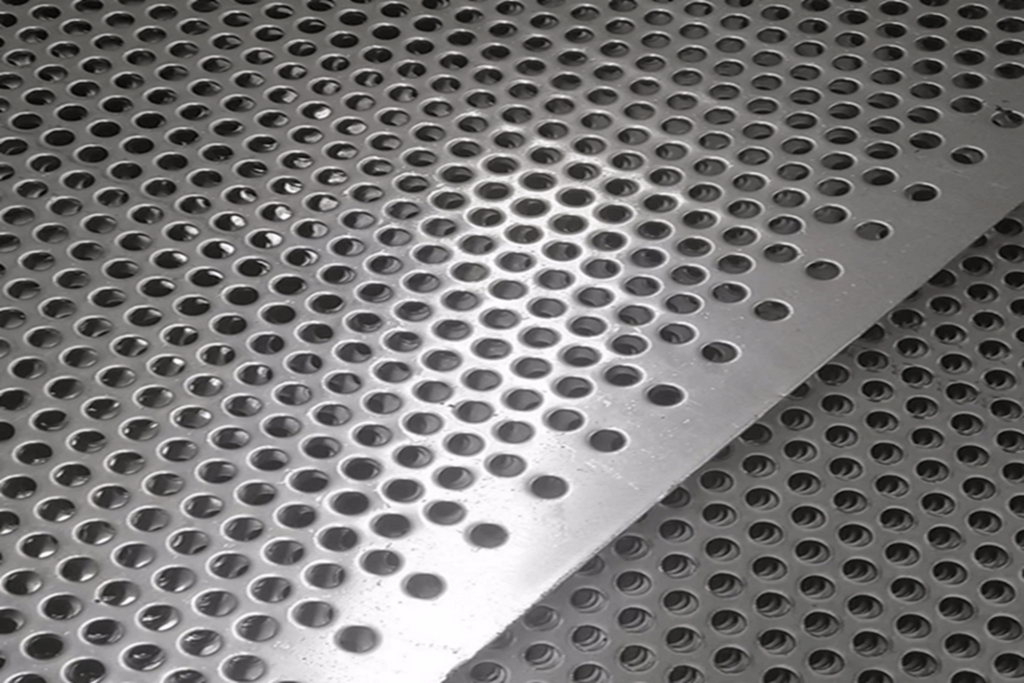

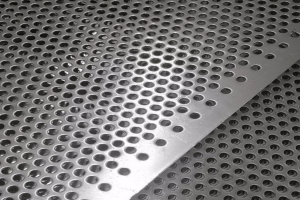

The Definitive Guide to Sheet Metal: My Comprehensive Journey from Raw Material to Finished Component

I. Introduction: Why Sheet Metal Captivates Me As an engineer who’s spent years designing and building everything from car bodies to skyscraper facades, I’ve come

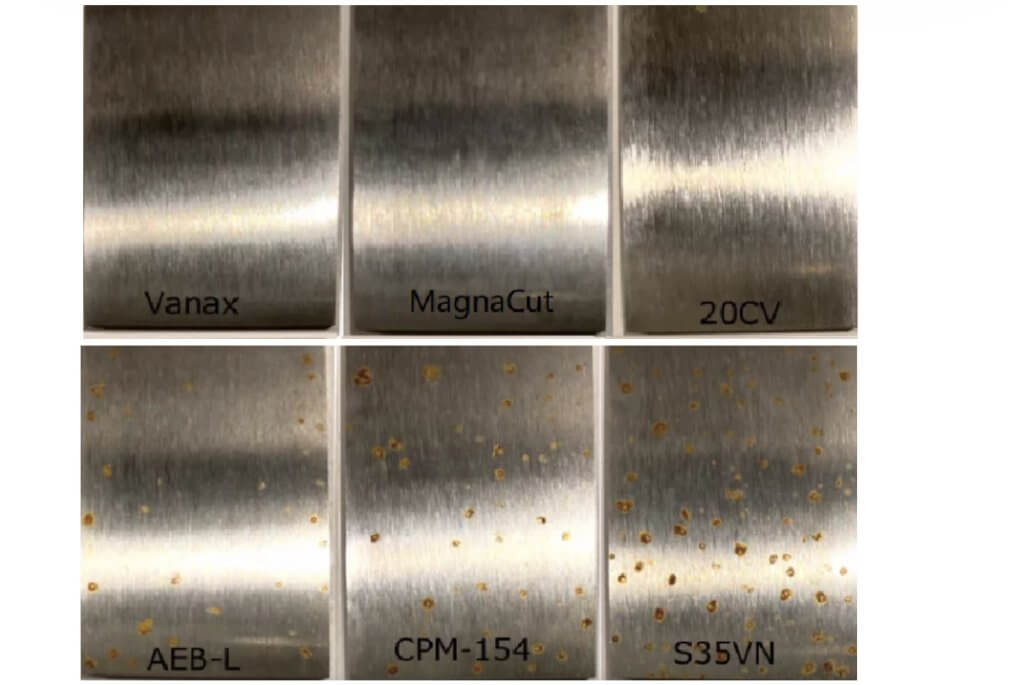

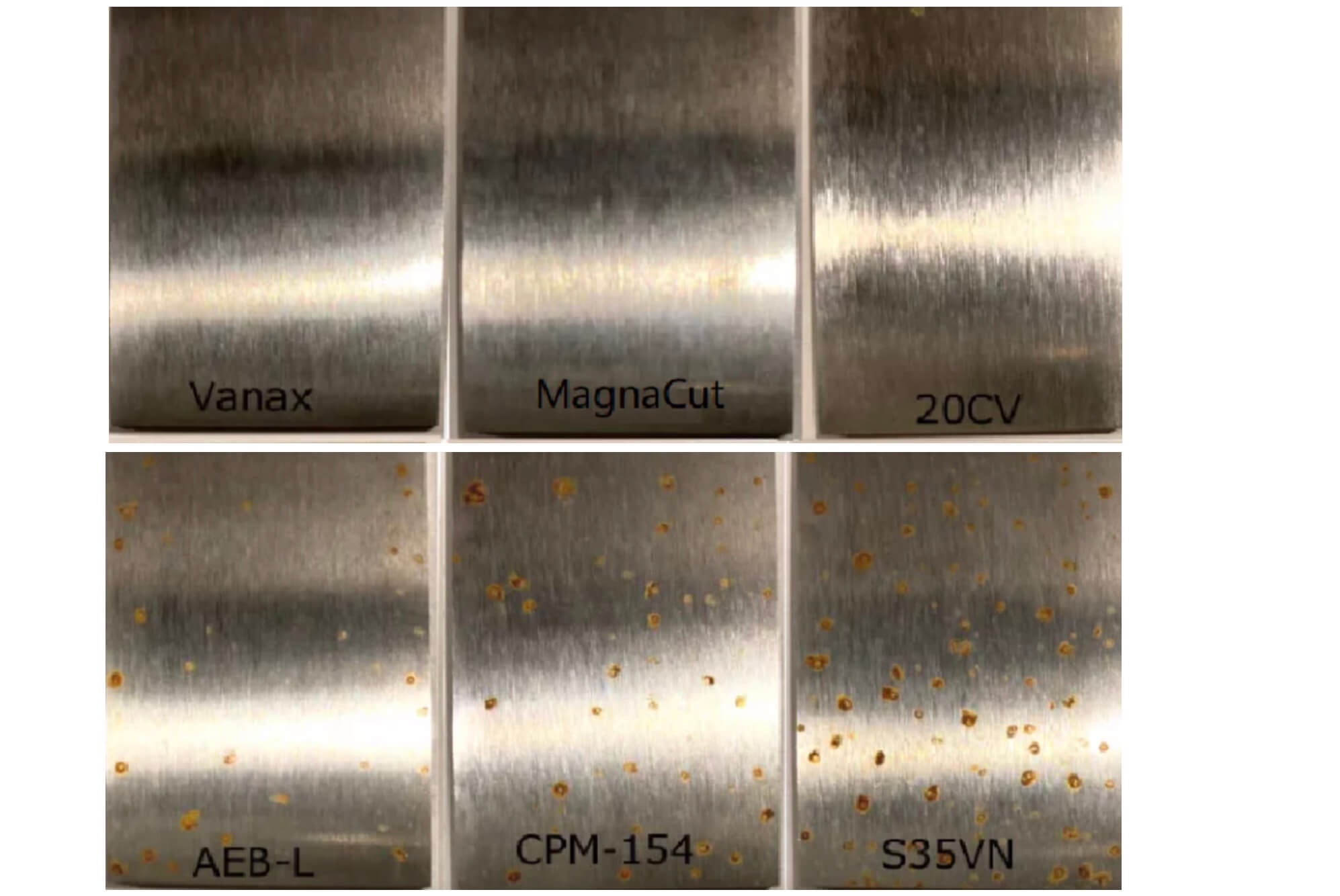

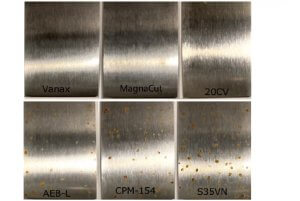

Mastering MagnaCut Steel with CNC: Tips for Precision Knife Crafting

Introduction MagnaCut Steel has taken the knife-making world by storm, and for good reason. This powder metallurgy stainless steel offers an incredible balance of hardness,

The Ultimate Guide to HSS Steel Cutting Tools in CNC Machining

I. Introduction: What is HSS Steel Cutting Tool? Understanding HSS Steel and Its Role in CNC Machining HSS Steel (High-Speed Steel) is a specialized alloy that’s

Best Cutting Tools and Feeds for HSS Steel Machining

I. Introduction: What is HSS (High-Speed Steel)? High-speed steel (HSS) is an alloy designed to withstand the intense heat generated during cutting operations. It’s not

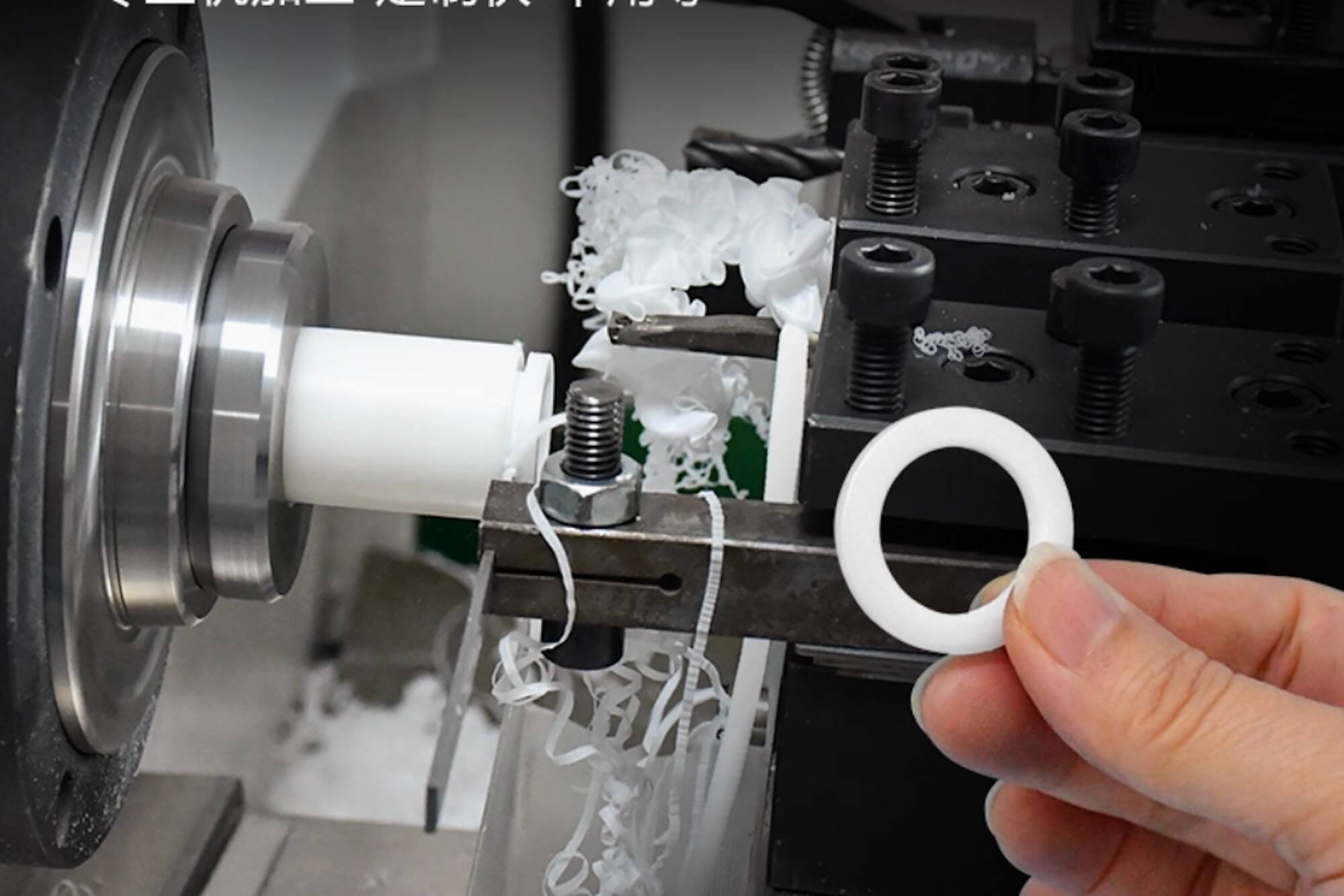

Plastic Washers Too Specific for Off-the-Shelf? CNC Machining Has the Answer

Introduction (Brief) Plastic washers often seem like simple, minor parts. I used to think the same—until I faced an issue where standard off-the-shelf plastic washers

S30V Steel CNC Machining Guide: Tools, Techniques, and Real-World Tips

Introduction When I first started working with S30V steel, I thought I knew what I was doing. I had years of CNC machining experience, a decent

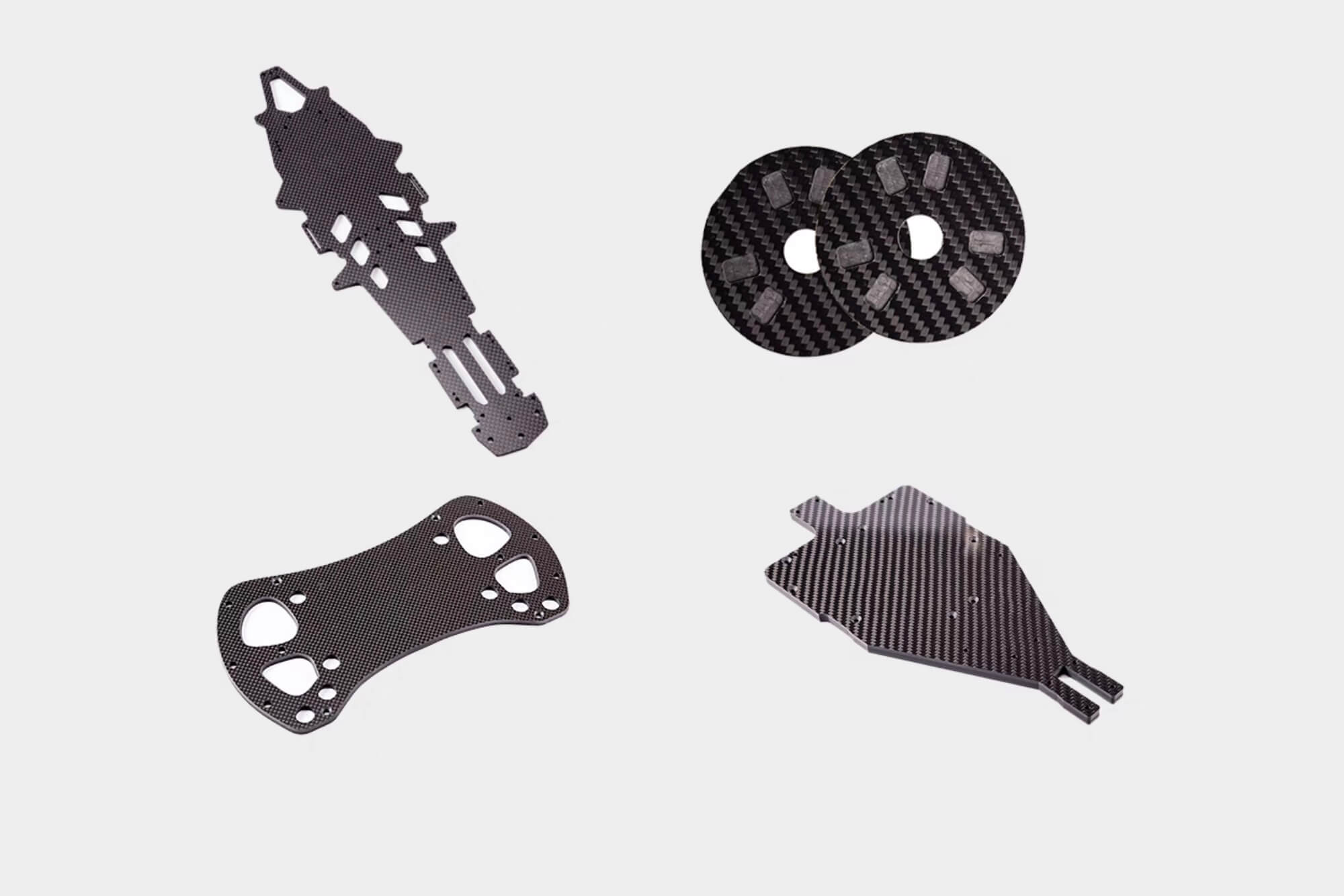

The Ultimate Carbon Fiber Case CNC Machining Manual for Custom Enclosures

Chapter 1: Introduction If you’ve ever held a carbon fiber case, you probably noticed how ridiculously light it feels—yet somehow, it feels tougher than metal. That’s

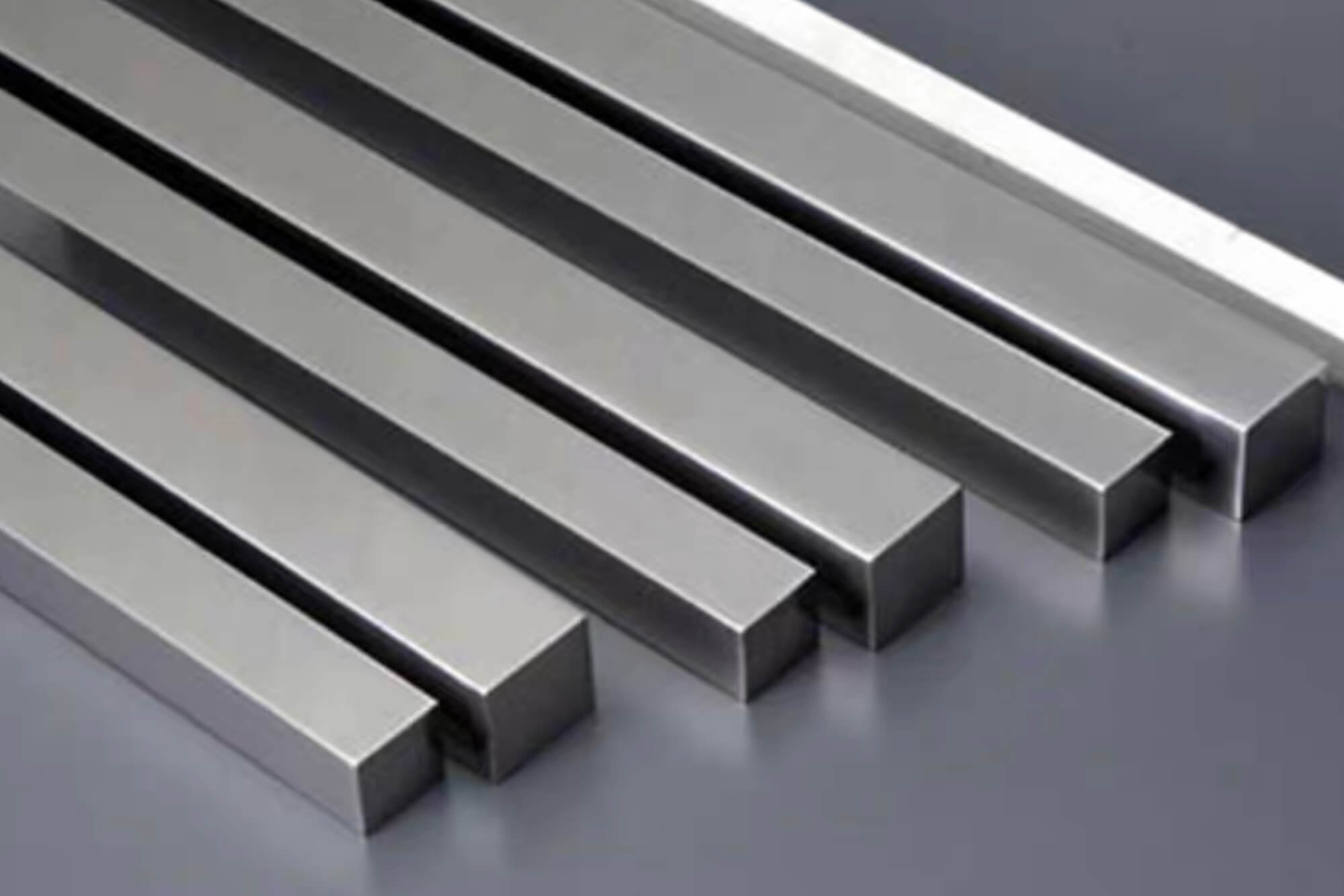

Which Titanium Plate to Choose for Machining? Material Grades, Machinability, and Supplier Tips

Why Choosing the Right Titanium Plate Matters When I first got involved in custom manufacturing, I underestimated just how significant the choice of material—especially titanium plate—could

Precision Meets Performance: A Comprehensive Guide to CNC Machining of M390 Steel

Introduction When I first encountered M390 steel, I wasn’t aware of the challenges and possibilities this remarkable metal offered. My experience began in a CNC workshop,

Engineering Drawings: A Practical Guide from Blueprint to Digital Twin

Introduction: The Language of Innovation Engineering drawings are the backbone of every engineering marvel, from towering skyscrapers to intricate medical devices. As a mechanical engineer

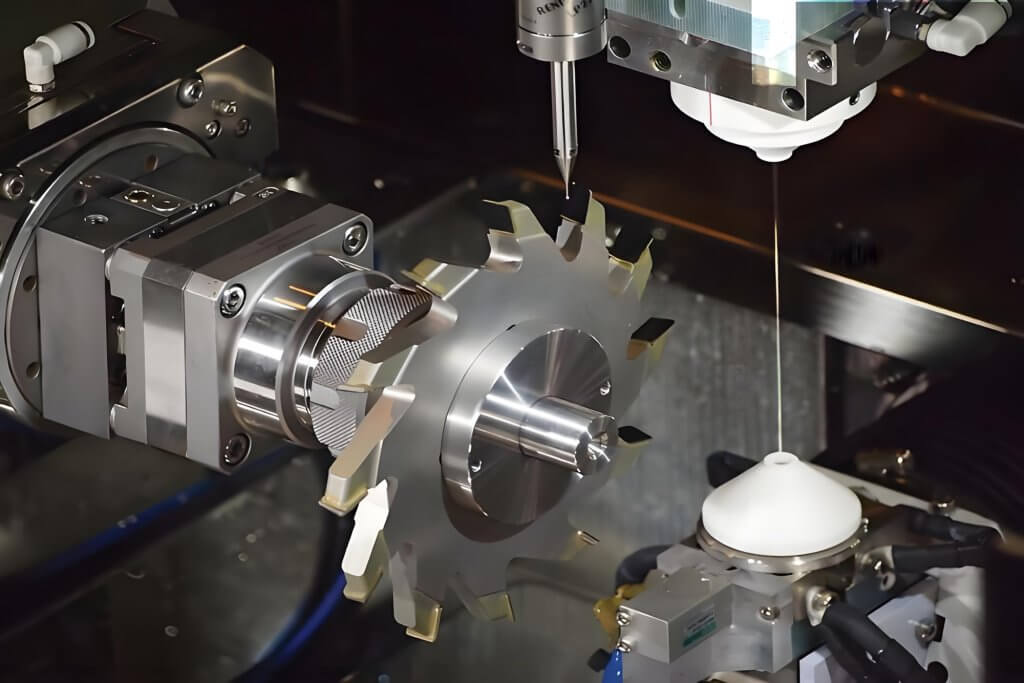

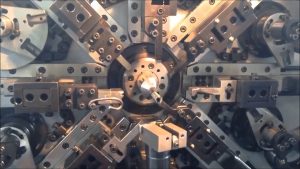

CNC Machine Shops: A Practical Guide to Precision Manufacturing

Turning a digital design into a tangible, high-precision component is a challenge I’ve encountered countless times in my career as an engineer. Whether you’re a

Machining the Impossible: An In-Depth Look at Wire EDM Technology

Introduction to Wire EDM: In my years working with advanced manufacturing, I’ve seen countless machining challenges—parts too intricate, materials too hard, or tolerances too tight

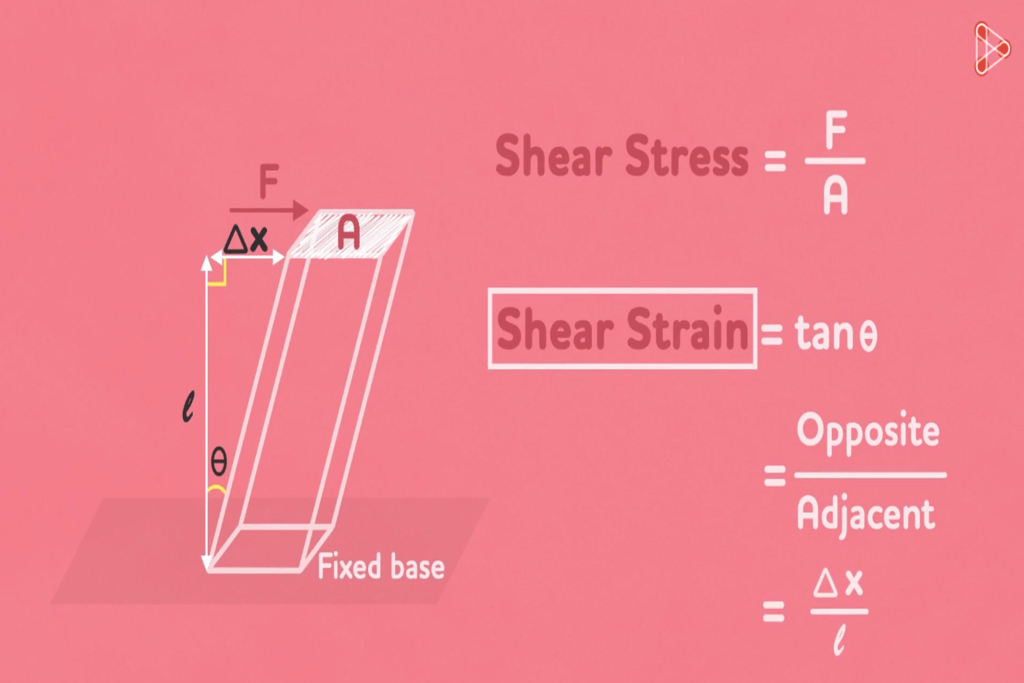

Mastering the Cut: A Definitive Guide to Shear Force in CNC Machining

Introduction As a machinist who’s spent years honing my craft in CNC machining, I’ve learned that shear force is the heartbeat of every precise cut.

Polyamide vs. Nylon: The Ultimate Engineer’s Guide to Properties, Types, and Applications

Introduction As an engineer with over a decade of experience in polymer applications, I’ve frequently tackled the polyamide vs. nylon confusion, especially when selecting materials

High-Performance Thermal Management: A Deep Dive into Large Heat Sinks

Introduction: As an engineer who’s spent years designing thermal solutions for data centers and renewable energy systems, I’ve seen firsthand how a large heat sink

Modern Aluminum Siding: Durability, Cost, and Style for Today’s Home

The Resurgence of a Modern Classic: An Introduction to Aluminum Siding When I embarked on the journey to revamp my home’s exterior, I sought a

The Definitive Engineer’s Guide to Crossed Roller Bearings: Precision, Rigidity, and System-Level Integration

Introduction In the pursuit of precision, rigidity, and compact designs, crossed roller bearings are pivotal in advancing engineering fields like robotics, medical imaging, and machine

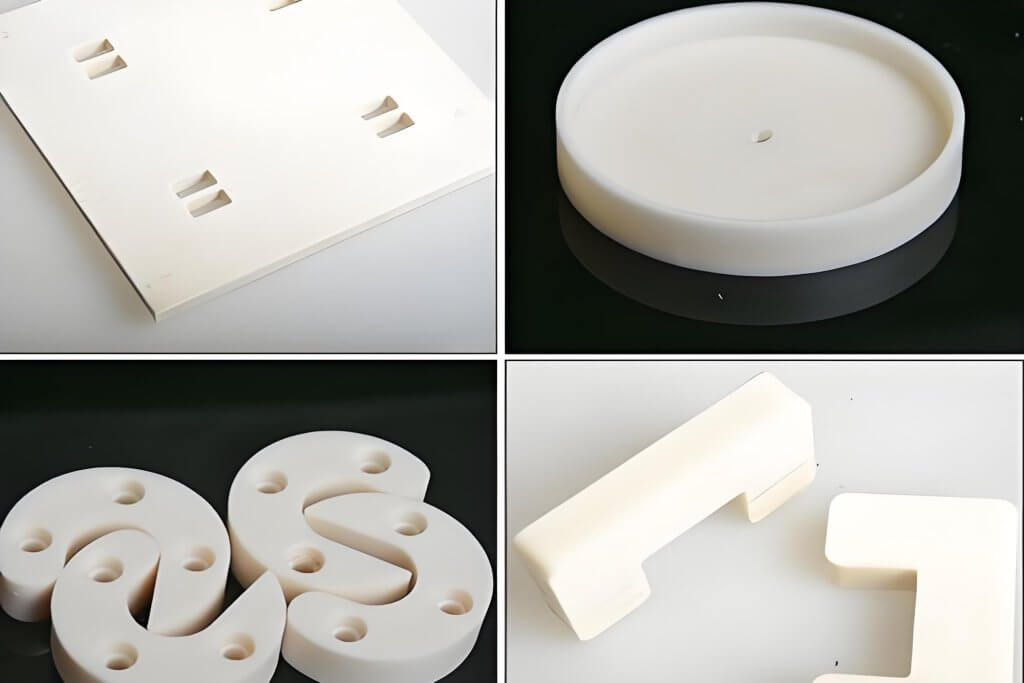

Plastic Shims: How to Make Custom Parts with CNC Machines

Introduction Plastic shims are one of those components you don’t think much about—until you really need them. I first got into making custom plastic shims

The Definitive Guide to Sheet Metal: My Comprehensive Journey from Raw Material to Finished Component

I. Introduction: Why Sheet Metal Captivates Me As an engineer who’s spent years designing and building everything from car bodies to skyscraper facades, I’ve come

Mastering MagnaCut Steel with CNC: Tips for Precision Knife Crafting

Introduction MagnaCut Steel has taken the knife-making world by storm, and for good reason. This powder metallurgy stainless steel offers an incredible balance of hardness,

The Ultimate Guide to HSS Steel Cutting Tools in CNC Machining

I. Introduction: What is HSS Steel Cutting Tool? Understanding HSS Steel and Its Role in CNC Machining HSS Steel (High-Speed Steel) is a specialized alloy that’s

Know Your Materials: Delrin

Introduction to Delrin Delrin, Polyoxymethylene (POM), known for its high tensile strength and durability, stands out in the realm of thermoplastics. Its molecular structure showcases

what are the different types of springs

Importance and Function of Springs Springs are indispensable mechanical components utilized in a myriad of applications to store energy, cushion impacts, maintain tension or compression

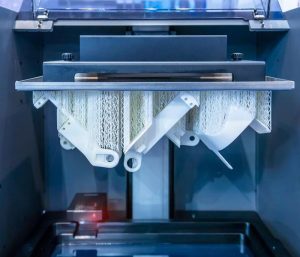

design for 3d printing how to reduce your cost

Relevance and Benefits of Cost Reduction in 3D Printing In an era where innovation is pivotal, 3D printing emerges as a transformative force across numerous

Delrin in CNC machining technology

Delrin, a trademarked name for polyoxymethylene (POM), is an engineering thermoplastic known for its high strength, rigidity, and resistance to friction and wear. This semi-crystalline

What Is the Difference Between Acetal Plastic and Delrin?

Brief Overview of Engineering Plastics Engineering plastics are a group of plastic materials that have better mechanical and thermal properties than the more widely used

Aerospace CNC Machining: Precision Engineering for the Skies

CNC (Computer Numerical Control) machining stands as a cornerstone in the production of aerospace components, where its application spells the difference between success and catastrophic

Delrin vs Nylon: Comparing the Properties and Applications of Two Popular Engineering Plastics

Engineering plastics have become foundational materials in the design and manufacturing of an array of components, owing to their mechanical strength, durability, and flexibility. Critical

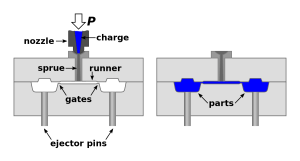

what is insert molding

Insert molding is a manufacturing technique where components, often metal parts, are placed into a mold and encapsulated by molten plastic to create a final

Precision Micro Injection Molding: Essential Advantages and Versatile Applications

Micro injection molding is a specialized form of manufacturing that enables the production of small and intricate plastic parts with high precision. It stands as

Ultimate Guide to CNC Drilling: Mastering Techniques, Varieties, and Practical Uses

CNC drilling is a precision machining process utilized extensively in the manufacturing sector where holes of various sizes and depths are created in metal, plastic,

CNC Milling vs CNC Drilling? which one to Choose?

In the context of manufacturing and industrial applications, Computer Numerical Control (CNC) processing plays a crucial role. Two such techniques integral to these operations are

Understanding the Different Types of Plastic for CNC Machining

Title: Understanding the Different Types of Plastic for CNC Machining Introduction CNC machining, a revered and precise manufacturing process, is not limited to metals and

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- bits

- blasting

- bolts

- brake

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- CNC Plasma

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- CNC Router

- cnc turning

- coating

- composite

- concentricity

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

- EDM

- electroplating

- elongation

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- gunmetal

- HDPE

- Heat Sinks

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- MagnaCut

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- NDT

- nipple

- nuts

- Nylon

- obj file

- PCB

- PEEK

- pewter

- Plastic

- pmma

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- shim

- silicone

- spring steel

- Stainless Steel

- Steel

- stl

- stp

- Strain

- strength

- stress

- stud

- supplier

- surface finishes

- Teflon

- tempering

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- urethane

- VMCs

- washer

- Waspaloy

- watch

- wire edm

- yield

- Zinc

- Zirconium

Engineering Drawings: A Practical Guide from Blueprint to Digital Twin

Introduction: The Language of Innovation Engineering drawings are the backbone of every engineering marvel, from towering skyscrapers to intricate medical …

CNC Machine Shops: A Practical Guide to Precision Manufacturing

Turning a digital design into a tangible, high-precision component is a challenge I’ve encountered countless times in my career as …

Machining the Impossible: An In-Depth Look at Wire EDM Technology

Introduction to Wire EDM: In my years working with advanced manufacturing, I’ve seen countless machining challenges—parts too intricate, materials too …

Mastering the Cut: A Definitive Guide to Shear Force in CNC Machining

Introduction As a machinist who’s spent years honing my craft in CNC machining, I’ve learned that shear force is the …

Polyamide vs. Nylon: The Ultimate Engineer’s Guide to Properties, Types, and Applications

Introduction As an engineer with over a decade of experience in polymer applications, I’ve frequently tackled the polyamide vs. nylon …

High-Performance Thermal Management: A Deep Dive into Large Heat Sinks

Introduction: As an engineer who’s spent years designing thermal solutions for data centers and renewable energy systems, I’ve seen firsthand …

Modern Aluminum Siding: Durability, Cost, and Style for Today’s Home

The Resurgence of a Modern Classic: An Introduction to Aluminum Siding When I embarked on the journey to revamp my …

The Definitive Engineer’s Guide to Crossed Roller Bearings: Precision, Rigidity, and System-Level Integration

Introduction In the pursuit of precision, rigidity, and compact designs, crossed roller bearings are pivotal in advancing engineering fields like …

Plastic Shims: How to Make Custom Parts with CNC Machines

Introduction Plastic shims are one of those components you don’t think much about—until you really need them. I first got …

The Definitive Guide to Sheet Metal: My Comprehensive Journey from Raw Material to Finished Component

I. Introduction: Why Sheet Metal Captivates Me As an engineer who’s spent years designing and building everything from car bodies …

Mastering MagnaCut Steel with CNC: Tips for Precision Knife Crafting

Introduction MagnaCut Steel has taken the knife-making world by storm, and for good reason. This powder metallurgy stainless steel offers …

The Ultimate Guide to HSS Steel Cutting Tools in CNC Machining

I. Introduction: What is HSS Steel Cutting Tool? Understanding HSS Steel and Its Role in CNC Machining HSS Steel (High-Speed Steel) …