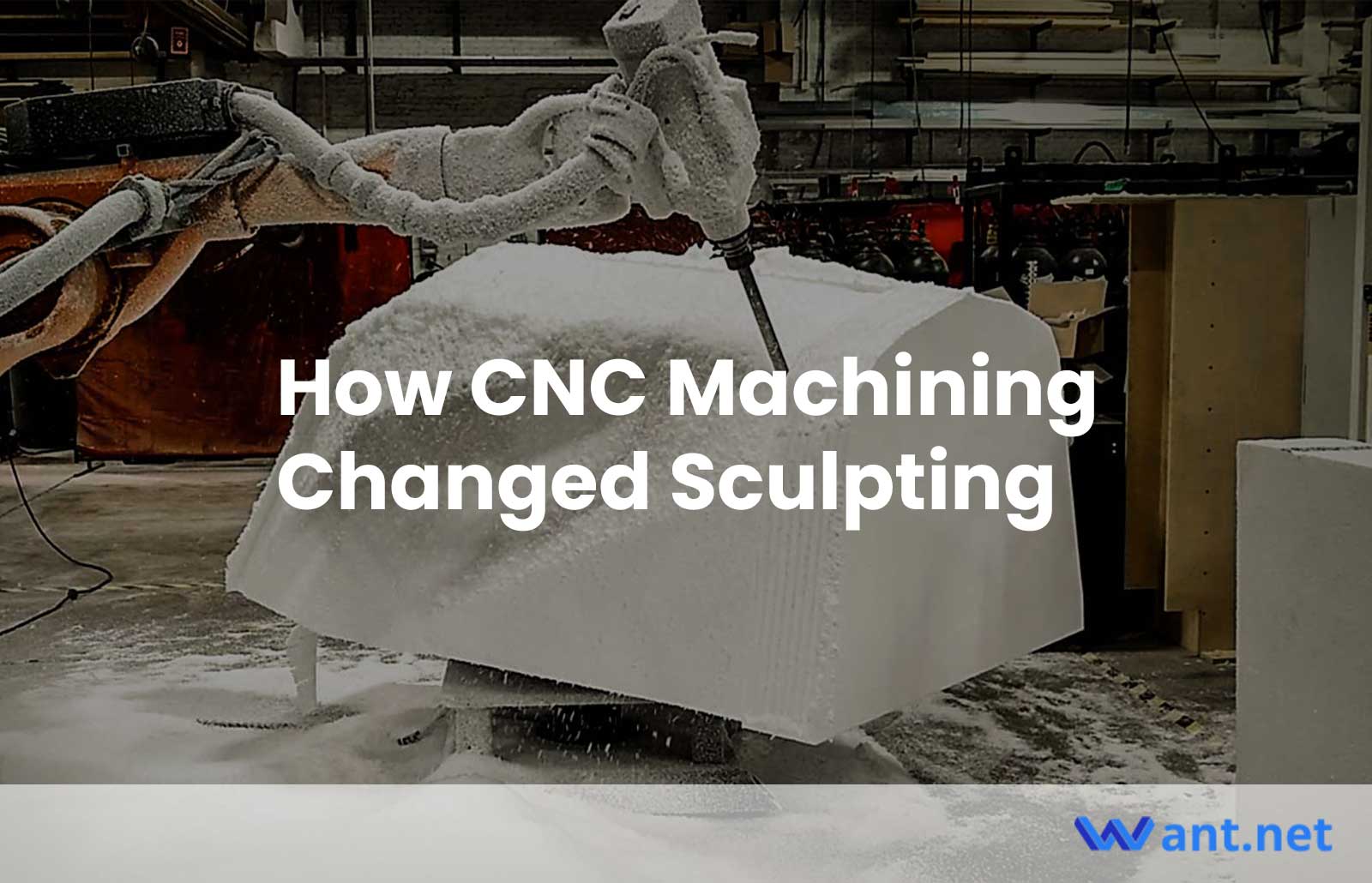

Art is a profound expression of human creativity, offering us a unique lens through which to view the world. Artists, whether painters or sculptors, leave a piece of their essence in their creations. However, the art of sculpting, in particular, required not only boundless imagination but also immense skill to shape and chisel a form from a solid block of stone. Thankfully, the advent of modern technology has democratized the art world, providing a unique opportunity for aspiring artists to unleash their creativity through custom manufacturing. This transformation has been made possible by the remarkable rise of CNC machining techniques.

The Evolution of CNC Machining in Art

CNC machining, an abbreviation for Computer Numerical Control machining, is a technology that enables cutting tools to move with exceptional precision based on a programmed program. Initially associated with industrial parts manufacturing, CNC machining has gradually found its place in various domains, including the realm of art.

Throughout history, the possibilities of art were often limited by two factors: human imagination and manual dexterity. However, CNC machining has broken through the barriers imposed by the latter. Its ability to effortlessly create intricate and freeform surfaces has proven invaluable in the field of sculpting. What was once considered unattainable or demanded decades of toil using manual tools can now be actualized within a matter of hours through the use of CNC machining centers.

Unleashing the Creative Potential

CNC machining bestows upon artists the power to bring their visions to life swiftly. Once the numerical control (NC) program is completed, artists can produce an infinite number of sculptures, provided they have the requisite raw materials. This not only provides a newfound sense of creative freedom but also unlocks unique opportunities for product manufacturing. CNC machining has elevated ordinary everyday objects into awe-inspiring works of art. By comparing a vintage car from the 20th century with its modern counterpart, one can be astounded by how machining technology has revolutionized the aesthetics of automobiles. Similarly, the transformative impact of CNC machining can be witnessed across a myriad of domains.

The Artistic Potential of CNC Materials

Art objects are intended to stand the test of time, often displayed outdoors and subject to the elements. Consequently, corrosion resistance becomes a paramount consideration when selecting materials for sculpting. Fortunately, CNC machining offers a diverse range of materials that can be expertly handled. Among the most prevalent materials for CNC sculpting are aluminum, copper, bronze, and wood.

These materials possess favorable machinability, making them ideal choices for sculpting using CNC machines. However, traditional sculptures often feature marble, granite, and other rock-based materials, which present unique challenges due to their hardness and brittleness. Cutting such materials necessitates specialized tools and coolants to prevent chattering and achieve the desired results. Precious metals like silver and gold also find their place in CNC sculpting, albeit primarily in the production of exquisite jewelry.

The Artistry of Cutting Tools

The selection of cutting tools in CNC sculpting is guided by two primary considerations: the desired surface outcome and the material being worked upon. Sculptures, with their organic forms and intricate details, often demand the use of machine tools capable of maneuvering complex freeform surfaces. Consequently, 3-axis and 5-axis milling machine tools are typically the sculptor’s tool of choice. These versatile tools require multiple mills and follow a meticulous approach. The initial step involves removing as much material as possible using an end mill, resulting in a stepped structure approximating the final geometry of the art piece. Subsequently, a ball-nose mill or CNC engraving mill takes center stage, meticulously refining the smaller and more complex features through a series of passes. It is crucial to approach the milling process from one side only, ensuring a superior surface finish.

When working with wood, specific tools featuring two flutes prove effective, as they effortlessly remove chips during the machining process. For steel, copper, and aluminum sculptures, high-speed machining metal cutters excel due to their robustness and rigidity, offering enhanced precision when compared to their wooden counterparts. However, when dealing with marble or granite, diamond tools reign supreme, effortlessly withstanding the hardness of these rocky materials.

Making Art Accessible: Translating Ideas into Reality

We find ourselves in a remarkable era where ideas hold greater value than the mastery of specific skills. With CNC machining, one need not possess the expertise of a machinist or the mastery of a seasoned sculptor to create art. Instead, all that is required is an idea and a willingness to invest. Let us consider a scenario where you have conceived a design for a CNC machined sculpture. What steps should you take to transform it into a physical masterpiece?

The first essential step is to create a detailed 3D model of your design. The level of detail in this model significantly influences the final outcome of your art piece. Depending on your preference, you can either sketch your design and engage the services of a specialist to bring your model to life, or you can embark on a journey to master 3D software, learning the tools necessary to create your own digital model. Although learning 3D modeling may initially appear daunting, it is undoubtedly more accessible and less arduous than traditional stone sculpting methods.

Once your 3D model is complete, the next phase involves manufacturing your art piece. CNC machine tools employ 3D models to execute their programs, shaping your design into reality. Although mastering the intricacies of the machining process itself may prove more challenging than 3D modeling, a multitude of CNC machine shops exist, offering their services at reasonable prices to help transform your vision into a tangible creation.

Exploring the Boundaries: Sculptural Possibilities in CNC Machining

While CNC machining has undeniably revolutionized the field of sculpting, it does have certain inherent limitations. Not all types of art objects can be effectively created using this technology. However, there are several prevalent examples of art forms that lend themselves particularly well to CNC machining:

1. Engravings:

As the name suggests, engravings involve creating patterns or low-depth carvings on plates. CNC machining excels in this domain, as the tools effortlessly reach the desired patterns, resulting in intricate and precise engravings.

2. Sliced Separate Sculptures:

A relatively new trend in wall art involves multiple planks positioned parallel to one another, with each plank contributing a portion of the overall design. CNC machining is exceptionally suited to this type of sculpture, as the planks can be installed and machined together as a cohesive unit, ensuring a seamless end product.

3. Marble Conventional Statues:

While machining marble statues can present considerable challenges due to their intricate details and hard-to-reach features, the production setup and techniques, when perfected, can yield exceptional results. Although more labor-intensive, the production of marble statues through CNC machining can be a worthwhile endeavor.

4. Art Implemented in Everyday Objects:

Artistic forms incorporated into everyday objects, such as doorknobs, spoons, forks, and boxes, often require complex sculptural elements. CNC machining empowers artists to realize their artistic vision, enabling the creation of functional yet captivating objects.

CNC machining has brought about a paradigm shift in the world of sculpting, enabling artists to push the boundaries of their creative expression. With its precision, efficiency, and versatility, this transformative technology has become an indispensable tool in the hands of artists and manufacturers alike, democratizing the world of art and fostering boundless innovationand ingenuity. As CNC machines continue to evolve and advance, we can only anticipate even more groundbreaking possibilities in the realm of programmed art.

In conclusion, the advent of CNC machining has revolutionized sculpting, ushering in a new era of artistic exploration and production. Artists, regardless of their traditional sculpting skills, now have the opportunity to turn their ideas into tangible art pieces with the help of this technology. By harnessing the precision and versatility of CNC machines, artists can create intricate and complex sculptures that were once deemed unattainable. Moreover, the wide range of materials that can be used in CNC machining allows for endless artistic possibilities.

While CNC machining has its limitations and not all types of art objects can be created using this technique, its impact on the art world cannot be understated. Engravings, sliced separate sculptures, marble conventional statues, and art implemented in everyday objects are just a few examples of the art forms that have found a natural fit with CNC machining.

As technology continues to advance, we can expect CNC machining to further expand the horizons of sculpting, pushing the boundaries of artistic expression. It is an exciting time for artists and art enthusiasts alike as the fusion of creativity and technology opens up new avenues for artistic exploration. With CNC machining as a powerful tool in the hands of artists, the future of programmed art looks incredibly promising.

Recommended Reads:

- 7 Amazing Projects You Can Create with CNC Mills

- Top 5 Materials Best Suited for CNC Milling

- 10 Key Features of CNC Mills You Should Know

- Understanding CNC Software: 8 Must-Know Tools for Success

- 5 Main Types of CNC Machines: A Comprehensive Guide

Related Posts

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Bead Blasting: The Secret to Quality CNC Machining(cnc machining tools Mavis)

The world of manufacturing has witnessed revolutionary changes with the advent of Computer Numerical Control (CNC) machining. It is a process used in the manufacturing sector that involves the use…

- Understanding CNC Machining: The Bead Blasting Process(cnc machining tools Valentina)

In the world of manufacturing, precision is paramount. One widely adopted method known for its precision is CNC machining. An integral subcomponent in the broader spectrum of CNC (Computer Numerical…