Threaded holes play a crucial role in the world of machining. They enable the creation of screw threads that are essential for fastening materials and components together securely.

You’ll find threaded holes in a wide range of manufactured products, from automobiles to aircraft. Their versatility and ease of use make them a common feature in various industries.

However, tapping threaded holes is not as simple as it may seem. To make the best choice for your projects, it’s important to understand the different threading technologies available. In this article, we’ll provide you with valuable information to enhance your understanding of tapped holes.

What is a Threaded Hole?

A threaded hole, also known as a tapped hole, refers to a hole with internal threads. It serves as a circular hole for the tapping and drilling processes. By using the tapping process, threads are created along the walls of the drilled hole. Threaded holes are typically used to connect two parts together using fasteners such as screws or bolts. These threads provide resistance, preventing the fastener from loosening over time and facilitating easy removal if necessary.

Understanding Tapped Holes

A tapped hole is a specific type of hole used to create internal threads. It involves drilling a hole in the material and then cutting threads into the walls using a tap. Tapped holes are commonly found in metal components that require secure fastening, such as those involving nuts and bolts.

Tapped holes share similarities with pilot holes, as both are used to create threads in a workpiece for the insertion of screws or bolts. However, the key difference lies in the fact that a tapped hole already has threads and only requires a tool to create the mating thread. On the other hand, a pilot hole needs to be drilled first before tapping can occur.

The Significance of Tapped Holes

Tapped holes are essential for machine parts, and CNC machines are commonly employed to create them. By tapping a hole, you can add threads to the walls of a drilled hole. Unlike machine screws, which cannot create their own threads, a tapped hole enables you to easily drive a screw or bolt into metal materials. This process is integral to CNC machining, ensuring that threaded elements are added effectively.

Why Create a Tapped Hole?

Let’s explore the importance of creating tapped holes for your projects:

- Enhanced Connection: Tapping a bolt or screw into metals allows for a more reliable attachment between two parts. The threading process enables a permanent connection, securing bolts, nuts, and screws to metal surfaces.

- Simplified Assembly: Tapped holes facilitate the easy assembly of small parts and products, streamlining the shipping process and reducing labor costs significantly.

- Ease of Use: By providing a designated space for screw fasteners, tapped holes enable the straightforward attachment of screws or bolts to metal materials without the need for pilot holes. Compared to the process of drilling bolts, nuts, or screws into wood, tapping a hole is a quicker alternative. It caters to project requirements, whether you need a through-hole or a blind hole.

Preparing for Tapping: Creating the Hole

Before tapping a hole, it’s crucial to ensure that the hole-making process results in straight, high-quality holes of the correct size. While modern machinery minimizes the need for oversizing factors in drilling, it remains essential to understand the proper technique for creating a hole before tapping.

A tapped hole is formed using a tap drill bit and a drill bit. The initial hole is made with a pilot drill bit, and the threads are then cut using a tap drill. The outer threads of a screw can be inserted into the internal threads created in the tapped hole. Some machinists still follow traditional rules and tap drill charts when creating threaded holes. However, it is important to carefully understand thread standards and the use of various tapping tools before initiating the tapping process.

Differentiating Blind Holes and Through Holes

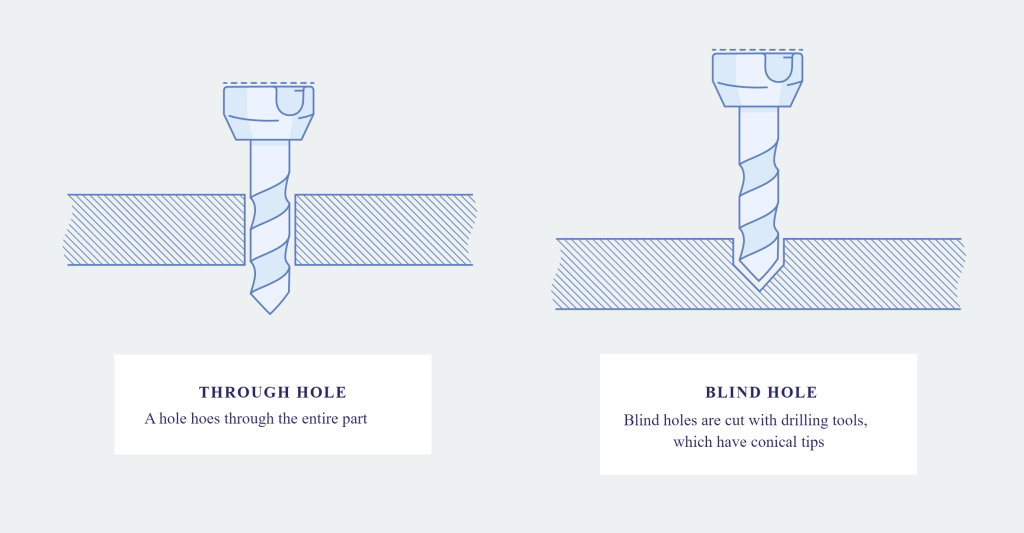

Threaded holes fall into two main categories: blind holes and through holes. Each type requires specific considerations to ensure easy machining.

Blind Hole

A blind hole has a specified depth and does not pass through the entire workpiece. The depth of the hole can end on a flat surface or taper into a cone. When creating a blind hole using an end mill, it will end on a flat surface. However, if a traditional mill is used, it may end with a cone shape. If it is required to extend the full thread to the bottom of the blind hole, a bottoming tap is used.

Dimensioning of a blind hole involves specifying the hole diameter and controlling the depth. The remaining material or the specified hole depth helps control the depth accurately.

Through Hole or Clearance Hole

A through hole extends completely through a part. Threaded holes are present on both sides of the part or workpiece. The thickness of the part determines whether the cutting tool or tap can thread the entire depth of the hole.

If the cutting tool or tap cannot thread a single side of the hole, several options can be considered:

- Add threads until allowed by the cutting tool or tap, noting that there will be no threads in a portion of the hole.

- Add threads on both sides until allowed by the cutting tool or tap, with the understanding that the threads from both sides may not align perfectly.

Drilling vs. Tapping: Understanding the Differences

The primary distinction between drilling and tapping lies in the sequence of operations and the tools used. Drilling is the initial process of creating a round and smooth hole using a drill bit. Tapping, on the other hand, involves using a tap drill bit and a drill bit to form threads on the interior of the hole. This process allows for the creation of threads by applying a tap to the hole’s interior.

Additionally, threads can also be created on the exterior of cylindrical objects using a die-cut process with a die. Bolts with threads serve as an example of a die-cut.

Three Types of Taps for Threading

There are three main types of taps designed to perform specific functions when it comes to threading:

- Plug Tap: The plug tap lies between the taper tap and the bottom tap and is often referred to as the “second tap.” Plug taps require more force to turn, as they cut more threads at once. They are commonly used to repair threads that need slight fixing and are suitable for tapping holes deeper than taper taps can reach.

- Taper Tap: Taper taps feature a conical tip with threads that have a slight angle, also known as a chamfer. The initial seven to ten threads are usually not fully formed. The tapered angle makes it easier to start the threads compared to using a bottom tap. Taper taps are primarily used to initiate new threads in a hole. However, they are not recommended for use in blind holes or when dealing with large holes or hard materials.

- Bottom Tap: A bottom tap is designed to start from the bottom of a hole when there is insufficient space to begin tapping from the top. It enables the cutting of threads throughout the entire depth of a through-hole. Bottom taps are useful for fixing mistakes made during tapping from the top and are commonly employed for threading shallow blind holes, deep threads in shallow holes, or creating new holes.

Tips and Considerations for Tapped Holes

To ensure the successful creation of tapped holes, it’s essential to consider the following tips and factors:

- Cutting vs. Forming: There are two methods for creating threaded holes—cutting and forming. The choice between these methods depends on factors such as hole size, machine lathes, material hardness, and whether it is a blind or through-hole. Cutting taps or traditional cutting methods are suitable for hole sizes up to M6, while larger tap sizes are needed for cutting threads requiring more machine power. Forming taps are recommended for non-ferrous soft metal materials, such as brass, lead, steel, and aluminum, as they prevent damage due to slower and more controlled cutting action.

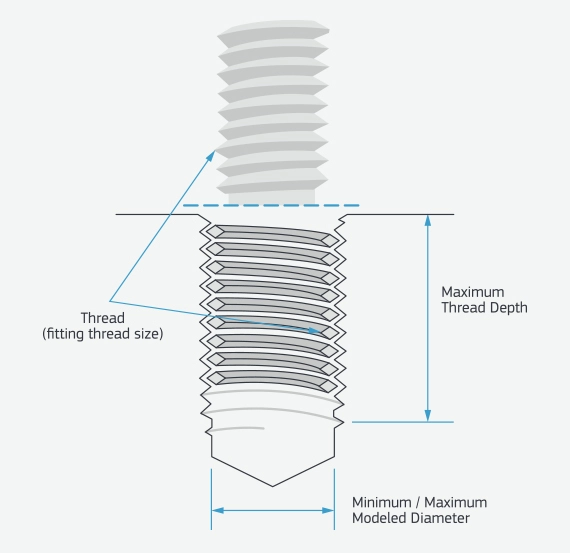

- Standard Thread Sizes: Whenever possible, it is advisable to use standard thread sizes for CNC machining. Standard sizes, such as 1/4-20, 3/8-16, and 1/2-13, ensure compatibility and reduce lead time and material usage. Metric thread sizes, such as M6 x 1.0, M8 x 1.25, and M10 x 1.5, are also commonly used. Working with standard thread sizes eliminates the need for specialized machining tools or materials, making the process more cost-effective.

- Appropriate Hole Diameter: It is crucial to ensure that the diameter of the threaded hole is suitable for the workpiece or part. The outer diameter of the threaded hole should be larger than the internal diameter, meaning that the internal diameter will be smaller. Placing a threaded hole too close to the edge of a part may result in thread breakage, as it could extend through the part’s side. This breakage can cause damage to cutting tools or taps and compromise the surface finish.

- Consider Angled Surfaces: Machining threaded holes into angled surfaces can pose challenges. One approach is to create a flat surface by machining pockets, allowing the addition of a threaded hole. However, if no angled surface exists, the threaded hole must be added to the part before machining the angled surface. It’s crucial to ensure that the depth of the threaded hole aligns with the design after incorporating the angled surface.

- Types of Threaded Holes: Threaded holes can be classified into two types: blind threaded holes and through holes. Both types require careful consideration during part design to ensure successful threading and prevent interference with other components. Blind threaded holes do not pass completely through the part, while through holes traverse the entire workpiece. It’s important to account for these variations during the design phase to achieve the desired threaded holes without alignment issues.

- Depth of Hole: Machining deep threaded holes presents unique challenges compared to shallower holes. The increased depth results in more contact time between the cutting tool and the workpiece, generating additional heat and requiring greater cutting force. These factors increase the risk of tool breakage. To overcome this, it’s crucial to select appropriate cutting tools, closely monitor the machining process, and ensure tool breakage is avoided.

Conclusion

When it comes to tapping threaded holes, it is important to have a complete understanding of the manufacturing process. This way, you can ensure that the parts you produce are of high quality. While it may seem a little complicated, it is best to consult with experts in threading techniques.

At Want.Net, we boast two decades of experience in machining and a team of skilled engineers proficient in various threading techniques. We prioritize our clients’ needs and provide exceptional services. If you have any questions or require assistance with tapping or machining threads, don’t hesitate to reach out to us!

Recommended Reads:

- Logo & Character Processing: How to Choose for Your Prototype

- Using the Right Milling Technique: Down Milling vs. Back Milling

- 3 Effective Strategies for Cost Optimization in CNC Prototyping

- Working with CNC Machining Tolerances: Achieving Precision and Accuracy

- A Comprehensive Guide to CNC Milling of Curved Surfaces

Other Articles You Might Enjoy

- Enhancing CNC Machining with Smart Alloys: Shape Memory Metals vs. Traditional Alloys

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated shaping of materials. This technology relies heavily on the…

- Custom Aluminum CNC Machining: Quick Prototyping Solutions

Introduction to Custom Aluminum CNC Machining Custom Aluminum CNC machining, where CNC stands for Computer Numerical Control, is a subtractive manufacturing process that employs computerized controls to operate and manipulate…

- Applications and Advantages of Bronze CNC Machining

1. Introduction: The Enduring Allure of Bronze in CNC Machining In this opening section, we explore the timeless appeal of bronze as a material for CNC machining. From its rich…