In recent years, CNC machining centers have continuously evolved through innovation, resulting in the development of three-axis, four-axis, and five-axis machining centers, as well as turning-milling composite CNC machining centers. Today, we will discuss the distinct characteristics of three-axis, four-axis, and five-axis CNC machining centers.

Three-Axis CNC Machining:

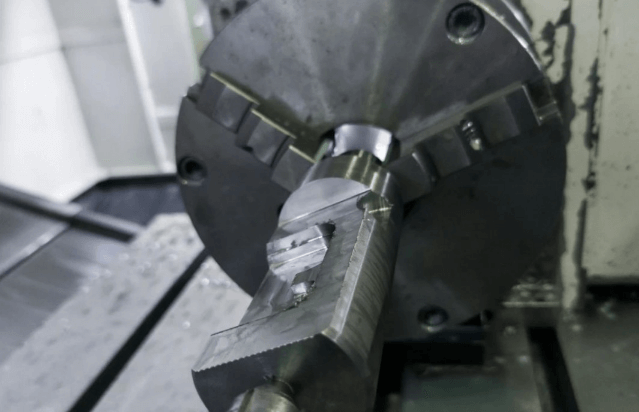

This typically involves three axes of movement in different directions, such as left-right, up-down, and front-back. Three-axis machining can handle one surface at a time, making it suitable for processing disc-like components.

Four-Axis CNC Machining:

In addition to the three linear axes, a rotational axis is added, which usually allows the base plane to rotate 360 degrees. However, it cannot operate at high speeds. This type of machining is more suitable for processing box-like components.

Five-Axis CNC Machining:

This includes an additional rotational axis beyond the four-axis setup, typically allowing the vertical plane to rotate 360 degrees. Five-axis machining centers enable comprehensive machining, allowing for single-clamp processing, which reduces clamping costs and minimizes the risk of scratching the product. They are especially suitable for processing components with multiple positions and surfaces, high precision requirements, and particularly strict shape accuracy.

Although five-axis machining centers have a significant competitive advantage over four-axis and three-axis centers, not all products are suitable for five-axis machining. Products suitable for three-axis machining may not be suitable for five-axis machining. Using a five-axis machining center for products that can be processed with a three-axis center can increase production costs and may not necessarily improve the outcome.

Related Posts

- Impeller five-axis CNC precision machining technology

The impeller is the most important part on the rotor, and is generally composed of a wheel disc, a wheel cover and a blade. An integral impeller is an impeller…

- From Two-Axis to Six-Axis: Evolution and Innovation in CNC Machining Parts

When you step into a modern machine shop, you can’t help but be amazed by the array of CNC machines at work. From simple two-axis lathes to complex six-axis turning…

- Comparing 3-Axis, 4-Axis, and 5-Axis CNC Machining Techniques

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry, enabling precise and efficient production of complex parts. One of the key differentiating factors in CNC machining is the number…

- Precision 5-Axis CNC Machining in the Automotive Industry

The automotive industry is an integral part of our daily lives, shaping our work commutes and leisure activities. Within this industry, CNC automotive technology plays a pivotal role, transforming the…

- Precision Rotor Blade Prototypes through 5-Axis Machining

Rotor blades are essential components in aero engines, responsible for converting the energy of a flowing medium into mechanical work. While many may find rotor blades mysterious, passionate engineers dedicate…

- Diversity in CNC Machining Parts: From Standard Lathes to Multi-Axis Turning Centers

Walk into any machine shop, and you'll likely see a variety of lathes humming away. These versatile machines are the backbone of many manufacturing processes, especially when it comes to…

- Impeller five-axis CNC precision machining technology

The impeller is the most important part on the rotor, and is generally composed of a wheel disc, a wheel cover and a blade. An integral impeller is an impeller…

- From Two-Axis to Six-Axis: Evolution and Innovation in CNC Machining Parts

When you step into a modern machine shop, you can’t help but be amazed by the array of CNC machines at work. From simple two-axis lathes to complex six-axis turning…

- Comparing 3-Axis, 4-Axis, and 5-Axis CNC Machining Techniques

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry, enabling precise and efficient production of complex parts. One of the key differentiating factors in CNC machining is the number…

- Precision 5-Axis CNC Machining in the Automotive Industry

The automotive industry is an integral part of our daily lives, shaping our work commutes and leisure activities. Within this industry, CNC automotive technology plays a pivotal role, transforming the…

- Precision Rotor Blade Prototypes through 5-Axis Machining

Rotor blades are essential components in aero engines, responsible for converting the energy of a flowing medium into mechanical work. While many may find rotor blades mysterious, passionate engineers dedicate…

- Diversity in CNC Machining Parts: From Standard Lathes to Multi-Axis Turning Centers

Walk into any machine shop, and you'll likely see a variety of lathes humming away. These versatile machines are the backbone of many manufacturing processes, especially when it comes to…

- 5 Axis CNC Machining of Titanium: Revolutionizing Aerospace Component Manufacturing?

5 Axis CNC Machining: Catalyzing Innovation in Aerospace Component Manufacturing In the realm of aerospace component manufacturing, 5 Axis CNC machining is a groundbreaking technology. Fundamentally, it refers to computer…

- Choosing Between 3- and 5-Axis CNC Machining for Complex Aluminum Parts

Introduction to CNC Machining CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed computer software to control the movements of factory tools and machinery. This technology plays…

- Evolution of Mills and Machining Centers: The Future of CNC Machining Parts

Stepping into the world of CNC machining, you quickly realize how pivotal mills and machining centers are in crafting precise parts. Over time, these machines have evolved significantly, transforming from…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Smart Choice for CNC Machining Parts: Comprehensive Analysis of Horizontal Machining Centers

When it comes to CNC machining parts, the type of machining center you choose can significantly impact the efficiency and quality of your work. Horizontal CNC machining centers (HMCs) are…

- 3 Axis Vs 5 Axis CNC Machining: Custom Precision Parts Cost

In modern custom CNC machining services, the need for high precision customized machining parts is rising. No doubt, COVID-19 has also put an impact on the cost of parts ranging from…

- Maximizing Efficiency with 5-Axis CNC Machining: A Closer Look

Introduction to 5-Axis CNC Machining and Its Efficiency The innovative world of production has introduced 5-axis CNC machining, a pivotal technology poised to revolutionize manufacturing processes. Short for Computer Numerical…

- 5-Axis CNC Machining of Titanium: Maximizing Precision and Efficiency in Aerospace Applications

Introduction to 5-Axis CNC Machining in Aerospace Applications The 5-axis Computer Numerical Control (CNC) machining is a technological innovation critical to the aerospace industry that brings about improved precision and…

- 5-Axis CNC Machining of Titanium: Exploring Cost and Production Efficiency?

Introduction to 5-Axis CNC Machining and its Role in Manufacturing Industry The revolutionary technique of Five-axis Computer Numeric Control machining, or simply 5-axis CNC machining, plays an integral role within…

- What is Micro Milling?

The ever-changing needs of the market necessitate constant updates and advancements in manufacturing technology. In order to maintain a competitive edge, manufacturers must keep pace with these changes or risk…

- Diving into Vertical CNC Machining Centers: From Programming to Specifications

When you step into a machine shop, the hum of CNC machines is a familiar sound. Among these, the vertical CNC machining center is a workhorse, particularly when it comes…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- What is Diamond Machining

Diamond machining has emerged as a game-changer in the realm of precision manufacturing. While traditional cutting methods have their limitations, the relentless development of new techniques and equipment has paved…

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…

- Why should I choose CNC multi-axis machining in China? What are the advantages?

I usually choose Chinese CNC machining factories when I need to custom manufacture parts in large quantities. These factories not only have advanced technology and equipment but also provide high-quality…

- Nickel vs. Cobalt Alloys in High-Temperature CNC Machining: A Detailed Analysis?

Nickel and Cobalt Alloys in High-Temperature CNC Machining Both Nickel and Cobalt alloys play an essential role in high-temperature CNC machining. These metal alloys are popular choices due to their…

- CNC Machining for Medical Applications: Compliance and Material Selection?

Introduction to CNC Machining in Medical Applications CNC or Computer Numerical Control machining is a manufacturing process wherein pre-programmed computer software dictates the movement of factory tools and machinery. This…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Custom CNC Machining for High-Tech Security Systems

Introduction to CNC Machining for High-Tech Security Systems Custom Computer Numerical Control (CNC) machining plays an integral role in the production of high tech security systems. It is a manufacturing…